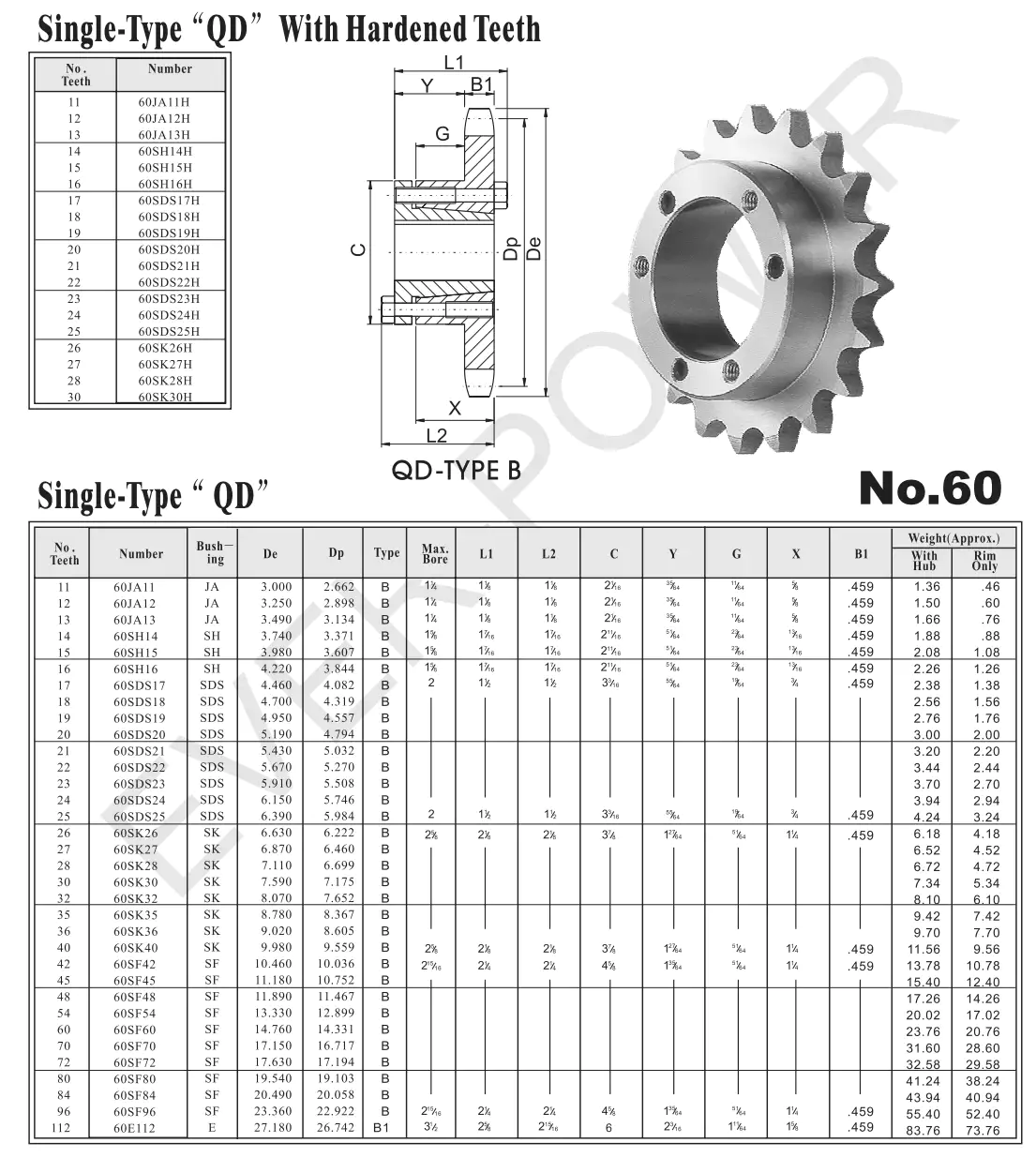

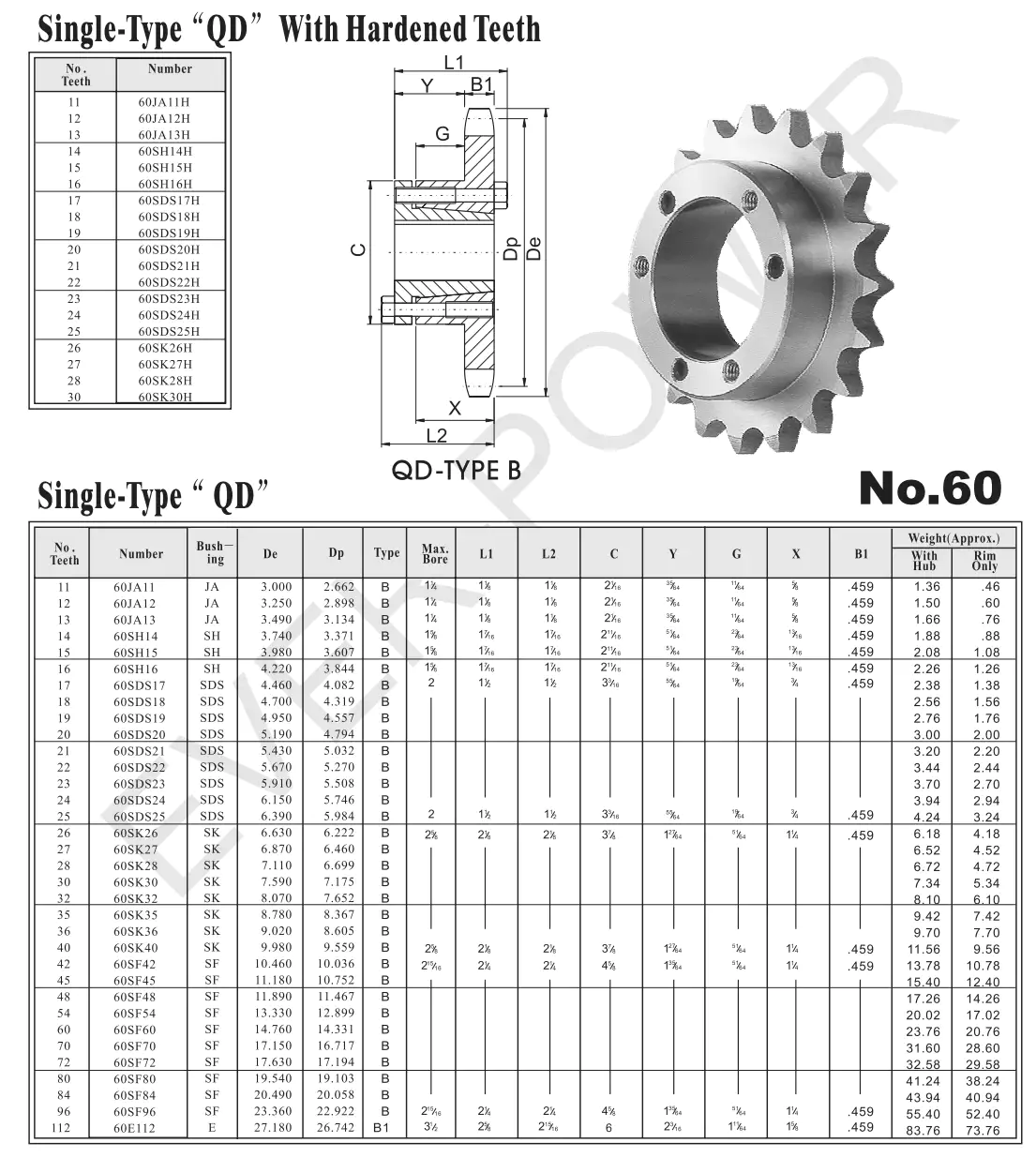

#60 3/4" Pitch QD Sprocket Specifications

QD Sprocket No.60 Single Type is a type of sprocket that belongs to the QD sprocket series. QD sprockets are widely used in various transmission systems. They are key components in power transmission systems, providing a reliable and efficient means of transferring torque and rotation between shafts.

Definition and Basic Structure

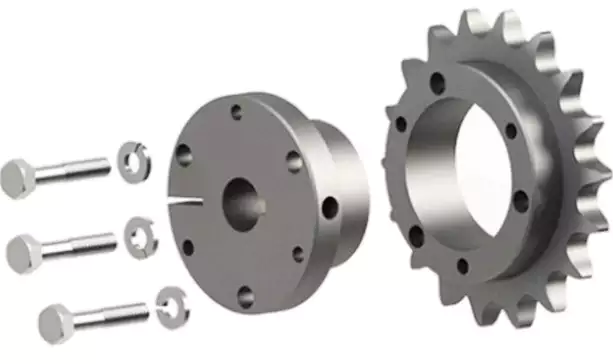

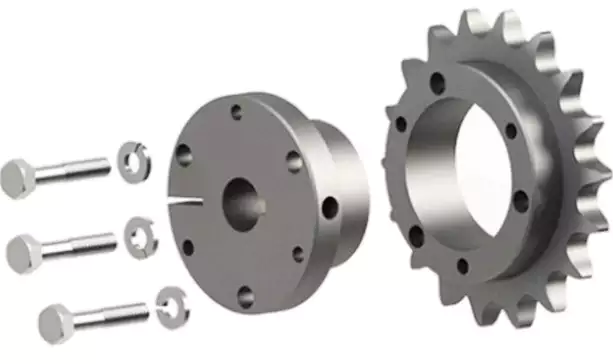

QD sprockets are designed with a durable and robust construction to ensure long-lasting performance. They consist of a hub, which is the central component, and teeth that engage with the chain. The hub is typically made of high-quality steel, ensuring strength and durability. The teeth are precisely machined to ensure smooth and efficient power transmission.

Characteristics and Functions of QD Bushing

- Easy Installation: QD bushings are designed for quick and easy installation, allowing for efficient assembly and disassembly of the sprockets.

- High Load Capacity: QD bushings can withstand high loads and ensure reliable power transmission.

- Standardized Design: QD bushings are available in standard sizes, allowing for easy interchangeability and compatibility with various sprocket types.

- Compact Design: QD bushings have a compact design, minimizing the space required for installation.

- Low Maintenance Cost: QD bushings require minimal maintenance, reducing maintenance costs and downtime.

One of the key advantages of QD bushings is their easy installation and removal process. This makes them highly convenient for applications where frequent sprocket changes or maintenance are required.

Installation and Disassembly Process of QD Bushing

- Prepare Tools and Materials: Gather the necessary tools and materials required for the installation or disassembly process, such as wrenches and lubricants.

- Clean Shaft and Sprocket Surface: Ensure the shaft and sprocket surfaces are clean and free from any dirt or debris that may affect the installation or disassembly process.

- Position the Sprocket: Position the sprocket on the shaft, aligning the keyway with the key on the shaft.

- Install QD Bushing: Slide the QD bushing onto the shaft, ensuring it is properly aligned with the sprocket and keyway.

- Secure the Sprocket: Tighten the QD bushing's locking screws to securely attach the sprocket to the shaft.

- Inspect: After installation, inspect the sprocket and QD bushing to ensure proper alignment and secure attachment.

Manufacturing Process of QD Sprocket

- Raw Material Preparation: Select high-quality steel as the raw material for the sprocket manufacturing process.

- Cutting: Cut the raw material into the desired shape and size to form the sprocket blank.

- Forging or Casting: Heat the sprocket blank and shape it through forging or casting to achieve the required strength and structure.

- Machining: Precisely machine the sprocket to create the teeth and other necessary features.

- Teeth Rolling: Roll the teeth to ensure accurate tooth profiles and enhance the sprocket's performance.

- Heat Treatment: Heat treat the sprocket to improve its hardness, strength, and wear resistance.

- Surface Treatment: Apply surface treatment, such as coating or plating, to enhance the sprocket's corrosion resistance and appearance.

- Quality Inspection: Perform rigorous quality inspections to ensure the sprocket meets the required standards and specifications.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing a wide range of high-quality sprockets and related products to meet the needs of various industries.

Introduction to QD Sprocket No.60 Single Type

QD Sprocket No.60 Single Type is a type of sprocket that belongs to the QD sprocket series. QD sprockets are widely used in various transmission systems. They are key components in power transmission systems, providing a reliable and efficient means of transferring torque and rotation between shafts.

Definition and Basic Structure

QD sprockets are designed with a durable and robust construction to ensure long-lasting performance. They consist of a hub, which is the central component, and teeth that engage with the chain. The hub is typically made of high-quality steel, ensuring strength and durability. The teeth are precisely machined to ensure smooth and efficient power transmission.

Characteristics and Functions of QD Bushing

- Easy Installation: QD bushings are designed for quick and easy installation, allowing for efficient assembly and disassembly of the sprockets.

- High Load Capacity: QD bushings can withstand high loads and ensure reliable power transmission.

- Standardized Design: QD bushings are available in standard sizes, allowing for easy interchangeability and compatibility with various sprocket types.

- Compact Design: QD bushings have a compact design, minimizing the space required for installation.

- Low Maintenance Cost: QD bushings require minimal maintenance, reducing maintenance costs and downtime.

One of the key advantages of QD bushings is their easy installation and removal process. This makes them highly convenient for applications where frequent sprocket changes or maintenance are required.

Installation and Disassembly Process of QD Bushing

- Prepare Tools and Materials: Gather the necessary tools and materials required for the installation or disassembly process, such as wrenches and lubricants.

- Clean Shaft and Sprocket Surface: Ensure the shaft and sprocket surfaces are clean and free from any dirt or debris that may affect the installation or disassembly process.

- Position the Sprocket: Position the sprocket on the shaft, aligning the keyway with the key on the shaft.

- Install QD Bushing: Slide the QD bushing onto the shaft, ensuring it is properly aligned with the sprocket and keyway.

- Secure the Sprocket: Tighten the QD bushing's locking screws to securely attach the sprocket to the shaft.

- Inspect: After installation, inspect the sprocket and QD bushing to ensure proper alignment and secure attachment.

Manufacturing Process of QD Sprocket

- Raw Material Preparation: Select high-quality steel as the raw material for the sprocket manufacturing process.

- Cutting: Cut the raw material into the desired shape and size to form the sprocket blank.

- Forging or Casting: Heat the sprocket blank and shape it through forging or casting to achieve the required strength and structure.

- Machining: Precisely machine the sprocket to create the teeth and other necessary features.

- Teeth Rolling: Roll the teeth to ensure accurate tooth profiles and enhance the sprocket's performance.

- Heat Treatment: Heat treat the sprocket to improve its hardness, strength, and wear resistance.

- Surface Treatment: Apply surface treatment, such as coating or plating, to enhance the sprocket's corrosion resistance and appearance.

- Quality Inspection: Perform rigorous quality inspections to ensure the sprocket meets the required standards and specifications.

Frequently Asked Questions (FAQ)

- Q: What are the advantages of using QD Sprocket No.60 Single Type?

- Q: How do I install a QD bushing?

- Q: What is the manufacturing process of QD sprockets?

- Q: How can I ensure the proper alignment of the sprocket and QD bushing during installation?

- Q: Are QD sprockets compatible with other types of chains?

A: QD Sprocket No.60 Single Type offers easy installation, high load capacity, standardized design, compactness, and low maintenance costs.

A: To install a QD bushing, prepare the necessary tools and materials, clean the shaft and sprocket surface, position the sprocket, slide on the QD bushing, secure the sprocket, and perform a final inspection.

A: The manufacturing process includes raw material preparation, cutting, forging or casting, machining, teeth rolling, heat treatment, surface treatment, and quality inspection.

A: Ensuring the correct alignment is crucial. Proper cleaning of the shaft and sprocket surface, as well as careful positioning and alignment of the keyway and key, are essential steps to achieve proper alignment.

A: Yes, QD sprockets are designed to be compatible with various types of chains, ensuring versatility and flexibility in different applications.

Our company specializes in providing high-quality sprockets, including the #60 3/4" Pitch QD Sprocket, to meet diverse industrial needs. We pride ourselves on our ability to offer not just standard sprockets but also customized solutions tailored to customer specifications. We welcome all customers to provide drawings or samples for non-standard customization to ensure the perfect fit for their applications.

Author: Miya

Additional information

| Edited by | Sylvia |

|---|