Bolter Miner Scraper Chain

The Bolter Miner Scraper Chain by GBC is a key transmission chain used in coal mines and other mining equipment. It is a transmission system that transcribes ores and coal from the mining face to the outside of the mine through scrapers. Due to its stability and durability under high-pressure and long-term operating conditions, this type of chain is widely used in coal mining equipment.

The scraper chain for coal mining of GBC is precisely designed to withstand extremely high tensile and impact forces, ensuring the smooth operation of continuous mining equipment in high-intensity working environments. The bolter miner chain we provide can effectively enhance production efficiency and reduce the failure rate.

Introduction

In the process of coal mining, the bolter miner scraper chain, as a key piece of equipment, bears the high-intensity load in mining operations. Whether in the complex underground working environment or in long-term heavy-load work, choosing a high-quality scraper chain for bolter miner is the key to ensuring efficient operation. The mining chains we provide feature outstanding wear resistance and high load capacity, meeting diverse mining demands and helping mining enterprises enhance productivity.

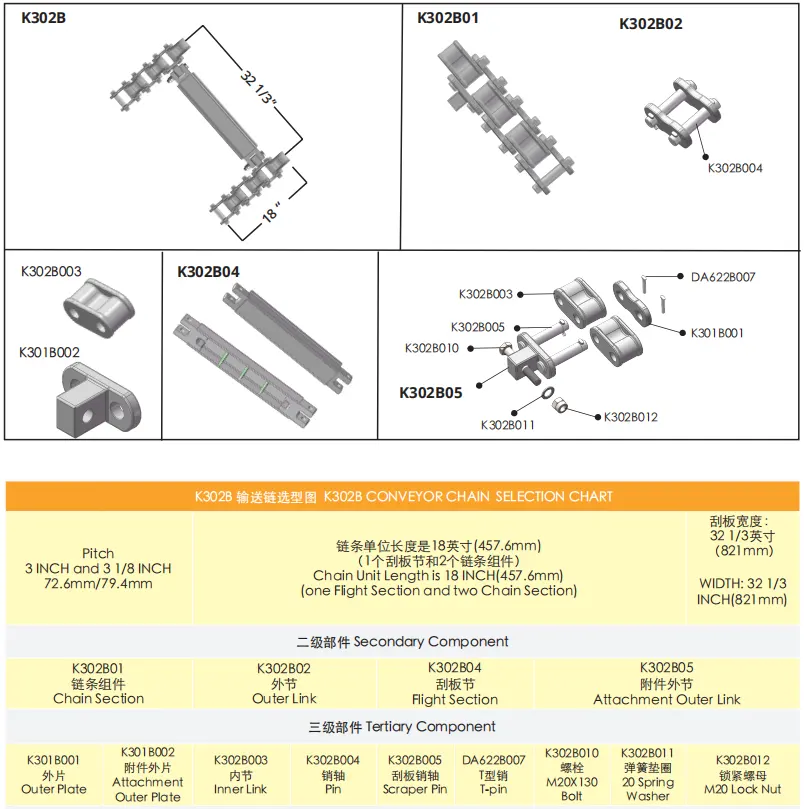

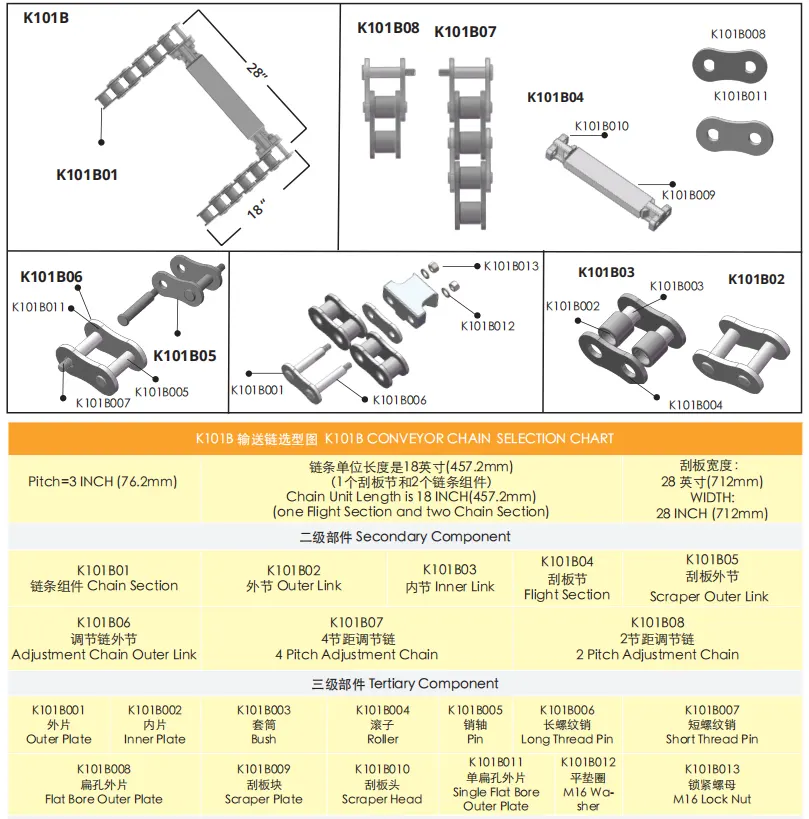

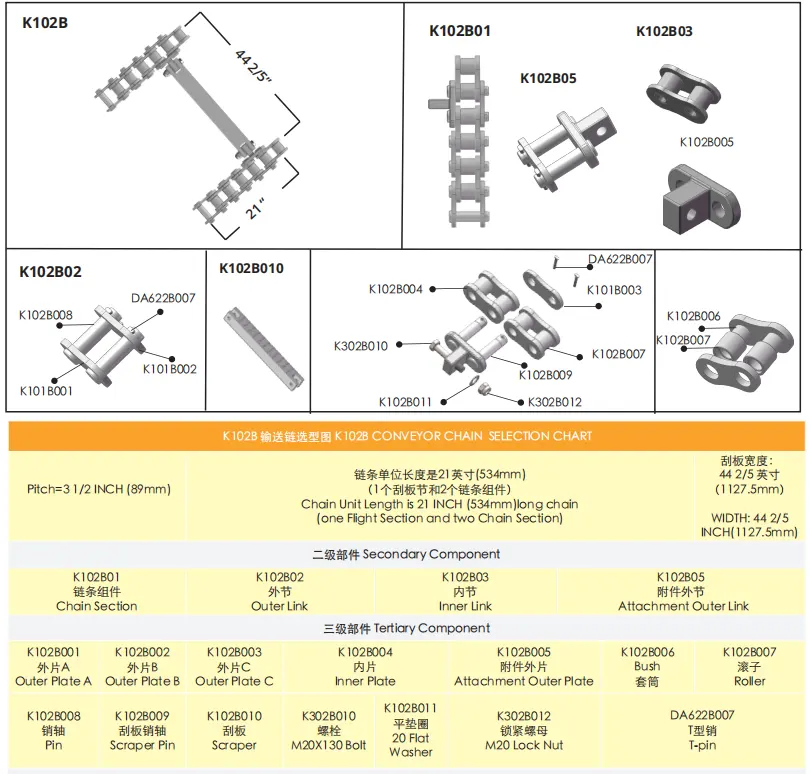

Product Information

Product Features

Choosing high-quality bolter miner scraper chain means choosing more efficient productivity and a longer service life. The chains of GBC have the following features:

- High wear resistance: Made of advanced materials, it can withstand high temperatures, corrosion and long-term wear.

- High load capacity: Applicable to Heavy Equipment, such as Bolter Scraper Chain for Heavy Equipment, ensuring the stable operation of mining equipment.

- Customized design: Provide Custom Bolter Miner Scraper Chain service according to customer requirements to ensure adaptation to different working environments.

We are committed to providing customers with the best solutions that meet their operational needs, helping them save maintenance costs and improve efficiency.

Bolter Scraper Chain Maintenance

Scraper chain maintenance for bolter miner is the key to extending the lifespan of the equipment and ensuring efficient operation. Proper maintenance can effectively reduce equipment failures and enhance the durability of the chain. We suggest regularly checking the wear of the chain and promptly lubricating and replacing it.

| Maintenance Item | |

|---|---|

| Regular Inspection | Inspect the wear and tension of the Bolter Miner Scraper Chain. |

| Proper Lubrication | Maintain proper lubrication of the chain to reduce wear. |

| Timely Replacement | Replace the chain immediately if cracks or severe wear are detected to prevent failures. |

The correct maintenance method can extend the service life of the Bolter Scraper Chain for Heavy Equipment, reduce the downtime of the equipment, and ensure the continuity and stability of the operation.

About Us

As a professional bolter miner scraper chain manufacturers, we have rich industry experience and advanced production facilities. Our factory adopts a strict quality management system to ensure that every bolter miner scraper chain meets the highest standards.

We offer bolter mining chain wholesale services. Our products are exported worldwide, including markets in Europe, America, Asia and Africa, and are highly trusted by customers. Our after-sales service team is committed to solving customer problems and ensuring the efficient operation of the equipment.m GBC is the sales agent of Ever-power Group in Australia. The chains we offer at discounted prices are very popular in Australia. Currently, they are sold in states such as New South Wales, Victoria, and Queensland, covering cities like Sydney, Melbourne, Brisbane, Adelaide, and Perth.

Our mission is to become the most reliable scraper chain supplier for bolter miner in the mining industry, providing customers with high-quality products and excellent services.

FAQs

1. How to choose the appropriate bolter miner scraper chain?

Selecting the appropriate Bolter Mining Chain requires considering the requirements of the mining operation environment, including the type of ore, the load capacity of the equipment and the frequency of use. We offer professional consulting services to help you choose the best chain solution.

2. How long is the maintenance cycle of bolter miner scraper chain?

We recommend checking the condition of the chain every three months. According to the usage frequency and working environment, lubrication and maintenance should be carried out regularly to ensure the optimal performance of the scraper chain for continuous mining equipment.

3. Do you offer customized services?

Yes, we offer the Custom Bolter Miner Scraper Chain service, which can customize specific chains according to customer requirements to adapt to different mining operation environments.

Product Reviews

Our bolter miner scraper chain for sale has been adopted by numerous mining enterprises worldwide and has received unanimous praise from customers. The following are the feedback from some customers:

|

James Wilson, Mining Supervisor |

Liam Harris, Maintenance Engineer |

Thomas Bennett, Site Foreman |

|

The bolter miner scraper chain we installed performs reliably under tough conditions. Its durable alloy links reduce wear significantly, extending maintenance intervals. The chain’s smooth operation minimizes jams, improving productivity. Installation was straightforward, though initial alignment took some tweaking. Overall, it’s a solid component for our longwall setup, handling abrasive materials well. |

This scraper chain is robust, with chromium-carbide overlay plating that resists corrosion effectively. It handles heavy loads without excessive strain on the conveyor system. The dual sprocket design ensures stable performance during high-output shifts. We noticed some initial lubricant residue buildup, but regular cleaning sorted it. It’s a dependable choice for underground coal operations. |

The scraper chain’s integrated design with our Sandvik MB670 bolter miner boosts efficiency. The large bearing area in journals minimizes wear, even with constant use. It’s easy to maintain, with accessible adjustment mechanisms for chain slack. We had a small issue with debris accumulation, but the cleaning system handles it well. A reliable product overall. |

Contact Us Immediately for More Information

If you are interested in our bolter miner scraper chain or need a customized solution, please contact our sales team at any time. We will offer you professional advice and quotations. Our online consultation service is available 24/7 to support you. We look forward to cooperating with you to make your mine production more efficient and safer!

The Bolter Miner Scraper Chain by GBC is a key transmission chain used in coal mines and other mining equipment. It is a transmission system that transcribes ores and coal from the mining face to the outside of the mine through scrapers. Due to its stability and durability under high-pressure and long-term operating conditions, this type of chain is widely used in coal mining equipment.

The scraper chain for coal mining of GBC is precisely designed to withstand extremely high tensile and impact forces, ensuring the smooth operation of continuous mining equipment in high-intensity working environments. The bolter miner chain we provide can effectively enhance production efficiency and reduce the failure rate.