Excavator-Anchor Integrated Machine Transport Chain

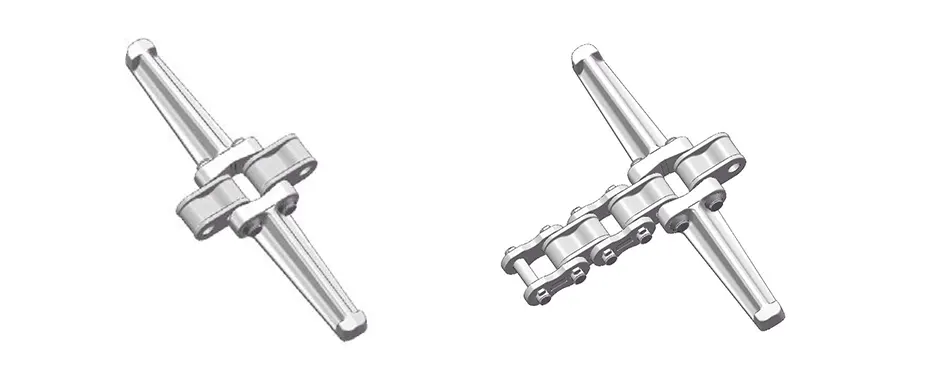

As a Excavator-Anchor Integrated Machine Transport Chain specifically designed for heavy machinery transportation, GBC’s DA644, DA646 and DA622 series products stand out with outstanding performance. Made of high-strength alloy steel and with precise manufacturing processes, the product can withstand tensile force and impact under extreme working conditions, ensuring the stable operation of excavator logistics chain in scenarios such as mining and road construction.

Introduction

- Integrated design reduces equipment switching time and enhances operational efficiency

- Compatible with the requirements of construction machine transport solution, and adaptable to continuous tunnel boring machines, drilling equipment, etc

- Extend the service life of heavy-duty transport chain through special heat treatment processes

Chain Specifications

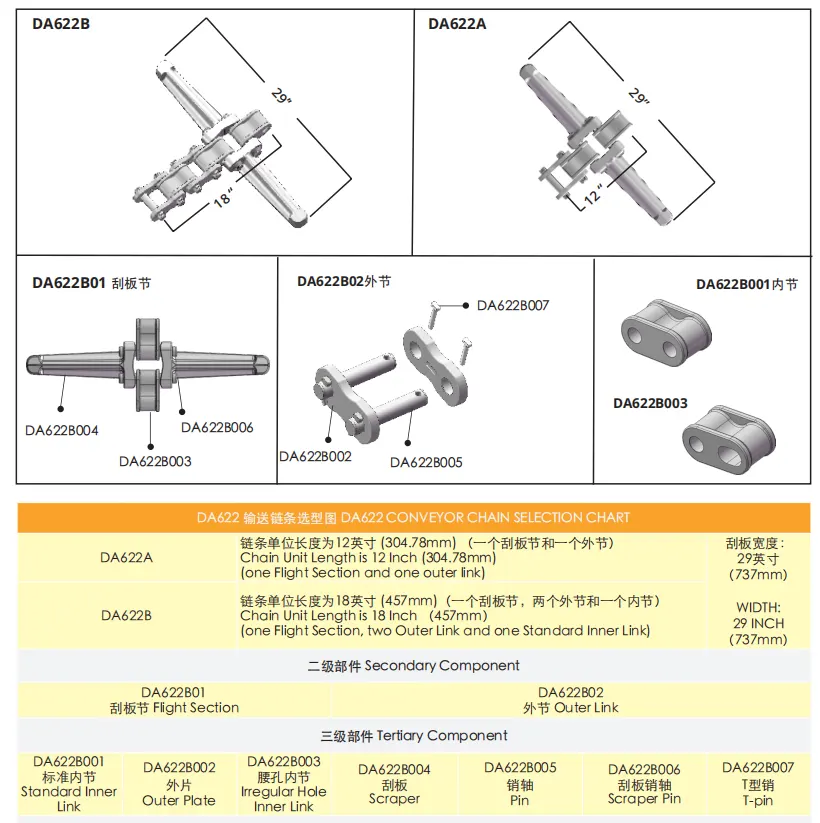

DA622 Conveyor Chain

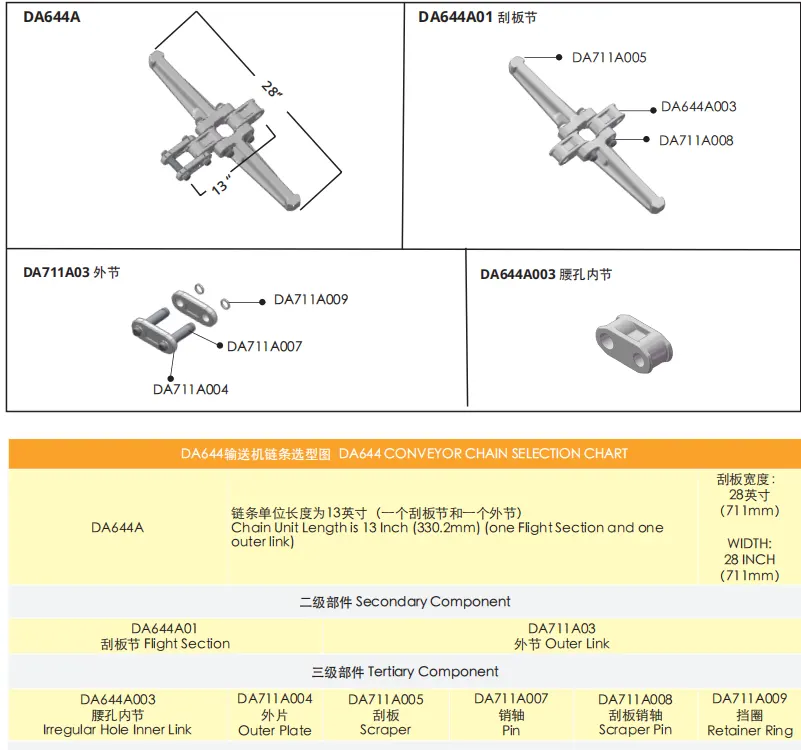

DA644 Conveyor Chain

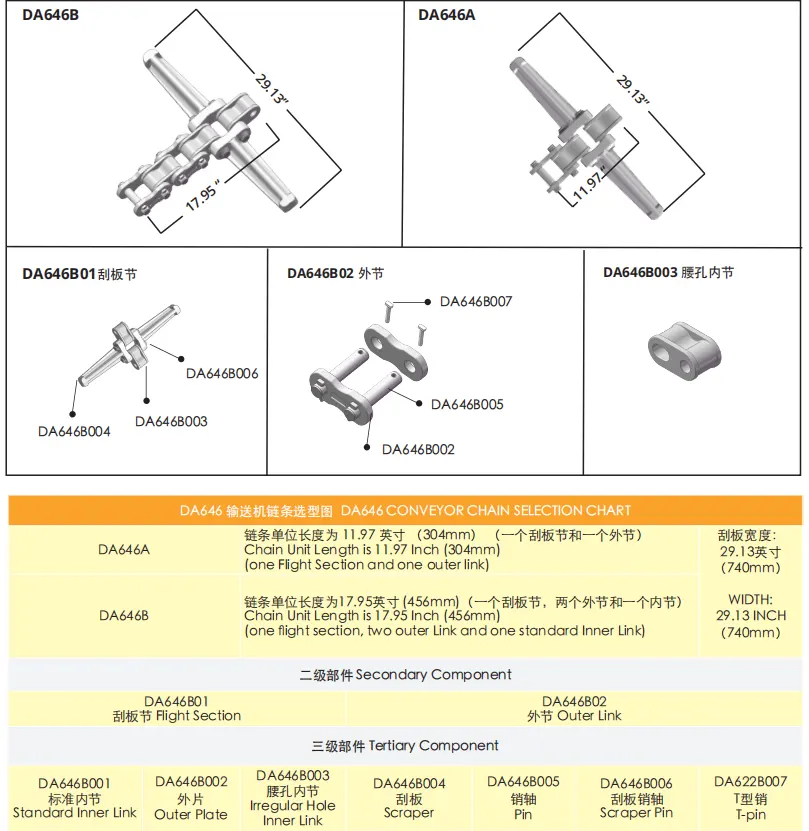

DA646 Conveyor Chain

Product Features

- Ultra-long service life and anti-wear design

The pins have undergone special heat-treated pin strengthening treatment, and their fatigue resistance has been enhanced by 40%

Galvanized anti-corrosion coating on the surface of the chain, suitable for damp and dusty heavy equipment chain for logistics scenarios - Low maintenance and ease of use

The modular structure supports easy installation and disassembly, saving downtime maintenance costs

The smooth chain operation technology reduces noise to below 75dB and improves the operating environment - Customized solutions

Provide custom transport chain for excavators services to match the requirements of equipment of different tonnages

Selected high-quality steel material, passed ISO 9001 quality certification

Applications

Our Excavator-Anchor Integrated Machine Transport Chain is specifically designed for high-intensity tunneling operations and is deeply adapted to the following core scenarios:

| Continuous Miner transportation | Fixation and transportation of Roadheader drilling machines | The road boring machine (Trencher) provides stable traction |

| In narrow Spaces such as coal mines and metal mines, the chain system provides stable chain operation to ensure the precise positioning and efficient transfer of continuous roadheaders. Integrated design reduces equipment switching time and enhances the operational efficiency of mining equipment. |

For rock crushing conditions, the product has enhanced impact resistance through special heat-treated pins, making it suitable for the high-frequency vibration environment of drilling and roadheader machines. The anti-corrosion treatment on the surface of the chain can resist the erosion of underground moisture and dust, and extend the service life of the heavy-duty anchor chain. |

In scenarios such as municipal pipeline laying and tunnel excavation, the chain system fixes the equipment with high tensile strength to prevent the risk of lateral tilt. The low-noise operation technology (≤75dB) complies with the environmental protection standards for urban construction and is suitable for the requirements of sensitive areas in road construction. |

Product Reviews

| Michael Thompson | Emma Johansson | Hiroshi Watanabe |

| We've been using the Excavator-Anchor Integrated Machine Transport Chain for three months. It's significantly reduced setup time and improved the overall stability during transport. The integration with our excavator equipment was smooth. The chain’s strength is reliable under load, especially in rocky terrain. It’s made a noticeable difference in our daily workflow efficiency. | This integrated transport chain simplified how we handle our excavation-anchor setup during transit. The anchoring components are solid and show no signs of fatigue. During our frost drilling work, the chain provided stability, especially helpful on frozen ground. It's a practical tool that fits well with our operational needs. | We used the integrated transport chain on a hillside stabilization project. It handled the equipment’s weight securely, even on sloped terrain. What impressed me most was the chain’s corrosion resistance after extended outdoor use. Our team found the locking mechanism intuitive, saving time during both setup and breakdown. |

Why Choose Us?

As an excavator transport chain supplier with more than 15 years of experience in the industry, we promise:

Technological leadership: Independently developed excavator chain transport system, which has passed the 2000-hour durability test

Localization service: As the Australian sales agent of Ever-power, we sell in large quantities in places such as Sydney and Melbourne, and offer a 48-hour emergency response

Cost optimization: The durable machine transport chain design reduces the replacement frequency by 30% and lowers the total life cycle cost.

As a Excavator-Anchor Integrated Machine Transport Chain specifically designed for heavy machinery transportation, GBC’s DA644, DA646 and DA622 series products stand out with outstanding performance. Made of high-strength alloy steel and with precise manufacturing processes, the product can withstand tensile force and impact under extreme working conditions, ensuring the stable operation of excavator logistics chain in scenarios such as mining and road construction.