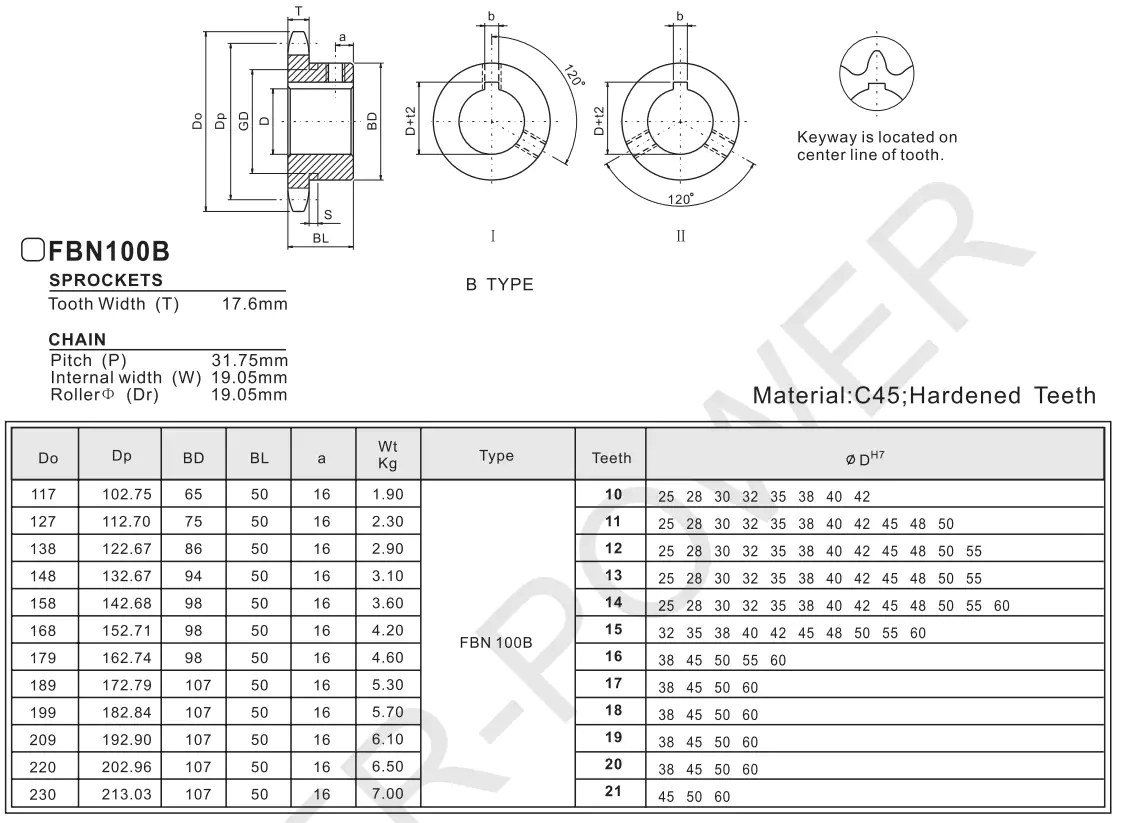

FBN100B Asian Standard Finished Bore Sprocket

The FBN100B Asian Standard Finished Bore Sprocket is designed for high-performance applications, ensuring durability and reliability in various industrial settings. Constructed from premium materials, this sprocket features precision engineering for enhanced efficiency and reduced wear. Its standard finished bore allows for easy installation and compatibility with a wide range of chains. Perfect for manufacturers seeking quality and performance, the FBN100B is an essential component in any machinery setup. Our company, GBC, proudly offers this product in Australia, ensuring local access to top-quality sprockets.

Specifications of FBN100B Asian Standard Finished Bore Sprocket

Introduction to Finished Bore Sprocket

A finished bore sprocket features a pre-machined hole designed to fit onto a specific shaft size. The FBN100B Asian Standard finished bore sprocket is one of the most prevalent types of sprockets utilized across various industries. It is recognized for its precision, durability, and straightforward installation.

Materials and Manufacturing Process

The FBN100B Asian Standard finished bore sprocket is constructed from high-quality materials, including high-carbon steel, alloy steel, or stainless steel. Material selection is contingent on the specific application and working conditions. The manufacturing process consists of material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, rust prevention, and quality testing.

- Material Selection: Selecting suitable materials is based on the specific application and working conditions. High-carbon steel is utilized for applications demanding high strength and durability. Alloy steel is preferred for increased wear and corrosion resistance. Stainless steel is chosen for applications requiring rust prevention and hygiene.

- Cutting: This process involves cutting the material into the desired shape and size using various cutting tools, including saws, laser cutters, or water jets.

- Stamping: Stamping entails punching or pressing the material into a specific shape using a stamping die.

- Forging: The forging process shapes the material by applying pressure with a hammer or press.

- Machining: Machining cuts the material to the desired dimensions and shape using various tools such as lathes, milling machines, or drills.

- Heat Treatment: This process involves heating and cooling the material to enhance its mechanical properties. The FBN100B sprocket undergoes quenching and tempering to achieve optimal hardness and toughness.

- Surface Hardening: Surface hardening improves wear resistance by hardening the sprocket's surface, achieved through induction hardening.

- Rust Prevention: Applying a coating or treatment to prevent rust is essential. The FBN100B sprocket receives a rust prevention treatment for extended service life.

- Quality Testing: Ensuring the finished product meets required specifications involves quality testing, including dimensional inspection, hardness testing, and surface inspection before customer shipment.

Applications of Plate Wheel Sprocket

Plate wheel sprockets find applications across various industries such as heavy machinery, food processing, chemical and pharmaceutical, assembly lines, logistics, and warehousing.

- Heavy Machinery and Equipment: Widely used in different types of heavy machinery, including construction, mining, and agricultural machinery.

- Food Processing and Packaging: Employed in food processing and packaging equipment, such as conveyor systems, filling machines, and labeling machines.

- Chemical and Pharmaceutical: Utilized in equipment for chemical and pharmaceutical processing, including mixing machines, drying machines, and tablet presses.

- Assembly Lines: Found in various assembly line equipment, such as conveyor systems, sorting machines, and packaging machines.

- Logistics and Warehousing: Used in logistics and warehousing equipment like conveyor systems, palletizers, and stackers.

Maintenance and Troubleshooting

Ensuring the long-lasting service life of the FBN100B sprocket necessitates proper maintenance and troubleshooting.

- Daily Inspection: Routine inspections include checking the sprocket for wear, damage, or misalignment. Any detected issues should be addressed promptly to prevent further damage.

- Cleaning: Regular cleaning helps eliminate dirt, debris, or contaminants that may lead to damage or wear.

- Lubrication: Adequate lubrication reduces friction and wear between the sprocket and chain, following the manufacturer's recommendations.

- Adjustment and Calibration: Proper adjustments ensure that the sprocket and chain operate correctly, with any misalignment issues addressed immediately.

Common issues with sprockets may include tooth skipping, breakage, wear, noise, and chain derailment, often arising from improper installation, lubrication, or incorrect chain tension. Solutions will vary based on the specific problem.

Other Types of Sprockets and Chains

Besides the FBN100B Asian Standard finished bore sprocket, we also offer various other sprocket types, including taper lock sprockets, QD sprockets, idler sprockets, and an array of chains.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, a renowned manufacturer of high-quality mechanical components. Our product range includes the FBN100B Asian Standard Finished Bore Sprocket, designed for optimal performance and durability in various applications. This sprocket is engineered to meet rigorous industry standards, ensuring reliability and efficiency in your operations.

In addition to our standard sprockets, we also offer custom solutions tailored to meet the unique requirements of our clients. Whether you need specific dimensions or unique designs, our team is ready to assist you with custom orders based on your drawings or samples. We invite all customers to reach out for bespoke sprocket solutions.

Additional information

| Edited by | Sylvia |

|---|

The FBN100B Asian Standard Finished Bore Sprocket is designed for high-performance applications, ensuring durability and reliability in various industrial settings. Constructed from premium materials, this sprocket features precision engineering for enhanced efficiency and reduced wear. Its standard finished bore allows for easy installation and compatibility with a wide range of chains. Perfect for manufacturers seeking quality and performance, the FBN100B is an essential component in any machinery setup. Our company, GBC, proudly offers this product in Australia, ensuring local access to top-quality sprockets.