Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel(SCM4404) Gear Rack

The GBC Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404) Gear Rack MHTGH Series offers exceptional durability and precision for demanding applications. This gear rack is engineered for high performance, featuring a helical design that reduces noise and enhances efficiency. As a leading manufacturer, GBC ensures top-quality materials and craftsmanship, making it the ideal choice for suppliers seeking reliability and strength in their mechanical systems. With its superior hardness and resistance to wear, this gear rack stands out in the market, providing unparalleled value for industrial use.

Introduction

The Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404) Gear Rack is designed for high durability and precision. Crafted from premium alloy steel, it features a helical tooth profile that ensures smooth operation and reduced noise. This gear rack is ideal for applications in machinery, automotive, and robotics. Our products stand out due to their exceptional strength, resistance to wear, and superior performance in demanding environments, ensuring long-lasting reliability for every project.

Product Parameters

| Manufacturing Description: |

| Precision Grade:DIN6h25 |

| Material:(SCM440 Chromium Molybdenum Alloy Steel)42CrMo4 |

| Type:Helical Rack |

| Treatment of Teeth:Ground |

| Hardness:High Frequency.HRC50~55Degree |

| Sides Ground:included |

| Right Hand Angle:19°31'42” |

| Pressure Angle:20 Degree |

| Total Pitch Error:0.036mm/1000mm |

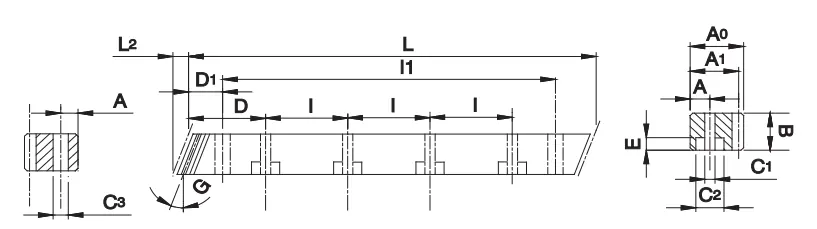

| 型号 Code |

模数 Module |

L | L2 | 齿数 Tooth No. |

B | A0 | A1 | D | I | 孔数 Hole No. |

A | C1 | C2 | E | D1 | I1 | C3 | ||

| MHTGH | 010 | 05 | 1 | 500.00 | 5.35 | 150 | 15 | 15 | 14 | _ | _ | _ | _ | _ | _ | _ | _ | _ | _ |

| MHTGH | 015 | 05 | 1.5 | 500.00 | 6.7 | 100 | 19 | 19 | 17.5 | 62.50 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| MHTGH | 015 | 10 | 1.5 | 1000.00 | 6.7 | 200 | 19 | 19 | 17.5 | 62.50 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| MHTGH | 020 | 05 | 2 | 500.00 | 8.5 | 75 | 24 | 24 | 22 | 62.50 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| MHTGH | 020 | 10 | 2 | 1000.00 | 8.5 | 150 | 24 | 24 | 22 | 62.50 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| MHTGH | 030 | 05 | 3 | 500.00 | 10.3 | 50 | 29 | 29 | 26 | 62.50 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 |

| MHTGH | 030 | 10 | 3 | 1000.00 | 10.3 | 100 | 29 | 29 | 26 | 62.50 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 |

| MHTGH | 040 | 05 | 4 | 506.67 | 13.8 | 38 | 39 | 39 | 35 | 62.50 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 |

| MHTGH | 040 | 10 | 4 | 1000.00 | 13.8 | 75 | 39 | 39 | 35 | 62.50 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 |

| MHTGH | 050 | 05 | 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.50 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 |

| MHTGH | 050 | 10 | 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.50 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 |

| MHTGH | 060 | 05 | 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.50 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 |

| MHTGH | 060 | 10 | 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.50 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 |

| MHTGH | 080 | 05 | 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.00 | 120 | 4 | 25 | 22 | 33 | 21 | 120.0 | 240.0 | 19.7 |

| MHTGH | 080 | 10 | 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.00 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 19.7 |

| MHTGH | 100 | 10 | 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.50 | 125 | 8 | 32 | 33 | 48 | 32 | 125.0 | 750.0 | 19.7 |

Applications

The Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404) Gear Rack is widely used in various industrial applications due to its durability and strength. Key applications include:

- Automotive Industry: Utilized in power transmission systems for smooth operation.

- Robotics: Essential for precise linear motion in robotic arms.

- Machinery: Employed in CNC machines for accurate positioning.

- Aerospace: Used in landing gear mechanisms for reliability under stress.

Assembly Instruction

The Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404) gear rack can be assembled to any desired length by connecting multiple racks together. During assembly, it is crucial to adjust the gap between the two gear racks to ensure proper meshing of the teeth. The installation of the gear racks requires the use of alignment pins to maintain precision and alignment.

- Position and secure the first gear rack using the alignment pins to ensure it is firmly in place.

- Utilize a reverse tooth gauge to position the next gear rack accurately, ensuring the teeth align perfectly for smooth operation.

- Individually check each connection point, using a gauge pin to measure the parallelism of the gear racks to guarantee optimal performance.

Follow these steps carefully to ensure a successful assembly of your gear rack system, maximizing efficiency and functionality.

Gear Rack Engagement

When it comes to the engagement of gears and racks, particularly those made from Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404), there are several critical factors to consider. This high-strength material offers enhanced durability and resistance to wear, which is essential for maintaining efficiency and longevity in mechanical systems.

One of the most important aspects of gear rack engagement is ensuring proper alignment between the gear and the rack. Misalignment can lead to increased wear and tear, reduced efficiency, and potential failure of the components. It is crucial to regularly inspect and adjust the positioning to maintain optimal performance.

Additionally, the precision in manufacturing the gear teeth and rack surfaces is vital. The helical design of the gear teeth allows for smoother and quieter operation compared to straight-cut gears, which can be particularly beneficial in applications requiring high precision and low noise levels.

Both the gear and rack play significant roles in the overall performance of machinery. The gear converts rotational motion into linear motion through the rack, making it an essential component in various applications, from robotics to automotive systems. The use of SCM4404 enhances the strength and reliability of these systems, ensuring they can withstand heavy loads and demanding conditions.

Why Choose GBC Gear Racks

GBC is the Australian sales agent for Ever-power, providing high-quality drive components at competitive prices. Our products are currently sold in New South Wales, Victoria, and Queensland, covering cities such as Sydney, Melbourne, Brisbane, Adelaide, and Perth.

With nearly 20 years of accumulated experience, Ever-power produces gear racks with a precision level that meets the German DIN3962 standard, with a maximum single rack length of 3200mm. We can manufacture straight and helical gear racks in various specifications ranging from 1 to 22 modules based on customer requirements.

Our Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404) gear racks are engineered for superior strength and durability, making them ideal for demanding applications.

Our commitment to customer service ensures that we support our clients throughout the purchasing process and beyond, providing expert guidance and reliable solutions.

The GBC Ground Hardened Helical Tetragonal Chromium Molybdenum Alloy Steel (SCM4404) Gear Rack MHTGH Series offers exceptional durability and precision for demanding applications. This gear rack is engineered for high performance, featuring a helical design that reduces noise and enhances efficiency. As a leading manufacturer, GBC ensures top-quality materials and craftsmanship, making it the ideal choice for suppliers seeking reliability and strength in their mechanical systems. With its superior hardness and resistance to wear, this gear rack stands out in the market, providing unparalleled value for industrial use.