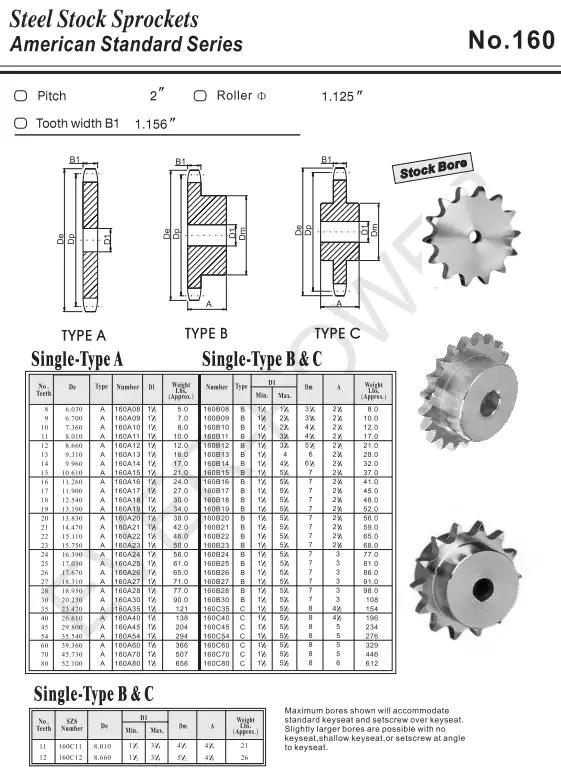

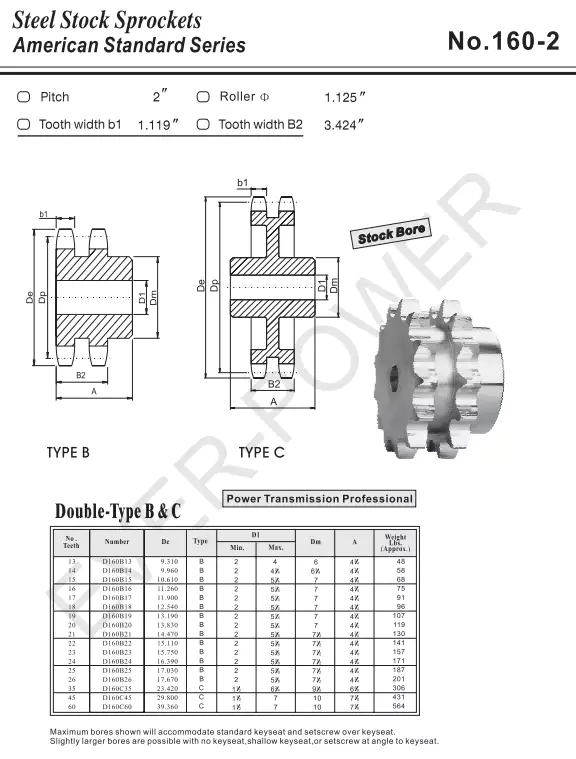

Machinable Bore Sprocket for ANSI 160 Roller Chain (2″ Pitch)

The Machinable Bore Sprocket for ANSI 160 Roller Chain (2″ Pitch) is designed for versatility and precision. Crafted from durable materials, it ensures optimal performance in various applications. This sprocket allows for easy customization to fit specific needs, making it an ideal choice for engineers and manufacturers alike.

GBC provides high-quality Machinable Bore Sprockets in Australia, ensuring reliability and performance in every product.

Specifications for Machinable Bore Sprocket for ANSI 160 Roller Chain (2" Pitch)

A machinable bore sprocket is a specialized mechanical component utilized across various sectors to facilitate motion transfer between two shafts using a roller chain. This type of sprocket features a circular disc equipped with precisely spaced teeth that engage with roller chain links, ensuring effective power transmission and seamless operation. The machinable bore allows for customization to fit different shaft diameters, enhancing versatility in applications.

Key Factors for Customizing Sprockets

- Material: Machinable bore sprockets can be crafted from high carbon steel, alloy steel, or stainless steel, tailored to meet specific application requirements.

- Tooth Profile: The design of the sprocket's teeth is crucial as it influences the engagement and smooth performance of the roller chain.

- Number of Teeth: The total teeth count on a sprocket directly impacts both the speed ratio and the torque transmission efficiency.

- Dimensions: Available in various sizes, careful selection of sprocket dimensions is essential for the intended mechanical application.

- Bore Size: The central hole in the sprocket must align with the shaft diameter for correct installation and function.

- Keyway: A keyway in the sprocket ensures a secure connection to the shaft, preventing any unwanted rotation.

- Surface Treatment: Often, sprockets undergo surface treatment processes, such as rust prevention, to boost durability and operational performance.

Applications of 2" bore sprocket

- Heavy Machinery and Equipment: Machinable bore sprockets are extensively used in industries such as construction, mining, and agriculture, where they enable power transmission in demanding heavy-duty applications.

- Food Processing and Packaging: In the food industry, these sprockets are integral to conveying systems, ensuring efficient production and packaging processes.

- Chemical and Pharmaceutical: The chemical and pharmaceutical sectors employ machinable bore sprockets in various machinery for their smooth and dependable operation.

- Assembly Lines: Vital components in assembly line frameworks, sprockets facilitate the movement of products throughout the production process.

- Logistics and Warehousing: Utilized in material handling equipment, conveyor systems, and storage solutions, sprockets enhance the efficient movement and storage of goods.

Maintenance and Troubleshooting

- Daily Inspection: Regular inspections should be performed to identify any signs of wear, damage, or misalignment in the sprocket.

- Cleaning: It's essential to maintain the sprocket’s cleanliness from debris and lubricant residues to ensure optimal functioning.

- Lubrication: Proper lubrication should be applied to reduce friction and significantly extend the lifespan of the sprocket.

- Adjustment and Calibration: Periodic adjustments of the roller chain’s tension and alignment with the sprocket are necessary for seamless operation.

Common Problems and Solutions

- Skipping Teeth: If teeth are skipping, inspect for worn teeth on the sprocket or inadequate tension in the roller chain. Replace the sprocket or adjust the tension as needed.

- Breakage: Check the sprocket for fatigue or overload signs. It may be necessary to replace it with a more suitable option for your application.

- Wear: Any significant wear could disrupt the chain’s engagement. Replacement of the sprocket may be required if it shows excessive wear.

- Excessive Noise: Unusual noise may suggest misalignment or improper lubrication, so inspect and rectify the issue accordingly.

- Chain Slack: If the chain consistently slips off the sprocket, it could be due to inadequate tension. Adjust this or replace the chain if necessary.

Plain 2" Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top sprocket suppliers in Australia. Our range includes high-quality machinable bore sprockets designed for ANSI 160 roller chains with a 2" pitch. These sprockets are manufactured with precision, ensuring optimal performance and durability in various applications.

At GBC, we prioritize quality in every product we offer, and our dedicated team provides exceptional pre-sales and after-sales support to ensure customer satisfaction. We understand the importance of responsive service and are always available to assist with any inquiries or concerns.

Additionally, we offer non-standard customization options to meet specific customer requirements, ensuring that you get the perfect sprocket for your needs.

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 160 Roller Chain (2″ Pitch) is designed for versatility and precision. Crafted from durable materials, it ensures optimal performance in various applications. This sprocket allows for easy customization to fit specific needs, making it an ideal choice for engineers and manufacturers alike.

GBC provides high-quality Machinable Bore Sprockets in Australia, ensuring reliability and performance in every product.