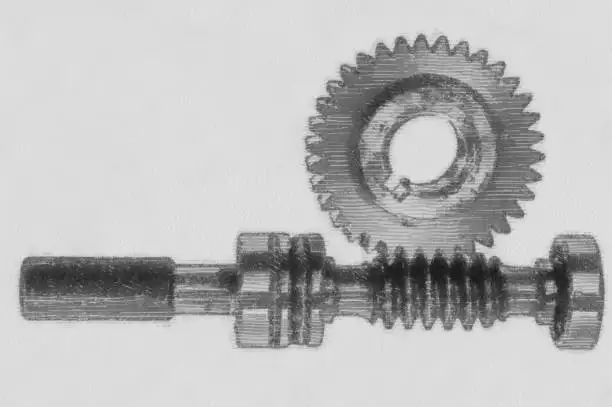

Magnetic Worm Gear

The Magnetic Worm Gear is a precision mechanical component designed to provide efficient power transmission. It consists of a worm gear that meshes with a worm wheel, allowing for high torque and reduced speed applications. Typically made from durable materials like aluminum or high-strength plastics, the worm shaft and worm screw are engineered to minimize friction and enhance performance. This gear system is widely used in robotics, automotive, and industrial machinery for its reliability and compact design.

Specifications of Magnetic Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Material | Aluminum Alloy |

| Max Torque | 50 Nm |

| Operating Temperature | -20°C to +80°C |

| Input Shaft Diameter | 10 mm |

| Output Shaft Diameter | 20 mm |

Features and Advantages of Magnetic Worm Gear

The Magnetic Worm Gear offers several compelling features and advantages:

- High Efficiency: The unique design of the Worm Gear ensures smooth operation, reducing energy loss.

- Compact Design: Its compact size allows for versatile applications, fitting into tight spaces without sacrificing performance.

- Durability: Made with high-quality materials, the Worm Wheel and Worm Shaft resist wear and tear, ensuring long service life.

- Precision Engineering: The integration of a Worm Screw enhances accuracy in motion transmission, making it ideal for precise applications.

- Magnetic Features: The Magnetic Worm Gear provides added stability and alignment during operation.

Applications of Magnetic Worm Gear in Modern Engineering

The Magnetic Worm Gear is an essential component in various mechanical systems, providing efficient power transmission. It features a unique design that includes a Worm Gear paired with a Worm Wheel, allowing for smooth and reliable operation. The Worm Shaft plays a crucial role in ensuring optimal performance, while the Worm Screw enhances the overall functionality. This gear system is widely used in robotics, automation, and other precision applications, demonstrating its versatility and efficiency in powering complex machinery.

Maintenance Tips for Magnetic Worm Gear

- Regular Lubrication: To ensure the optimal performance of your Magnetic Worm Gear, it is crucial to maintain proper lubrication. Using the right type of lubricant reduces friction between the Worm Gear and Worm Wheel, preventing excessive wear. Check the lubrication regularly, especially in high-load applications, as lack of sufficient grease can lead to premature failure of the Worm Shaft and Worm Screw. Aim to apply the lubricant according to the manufacturer's specifications, ensuring that the lubricant penetrates all moving parts effectively. This not only extends the life of the gear but also enhances its efficiency.

- Inspect for Wear: Regularly inspecting your Magnetic Worm Gear for signs of wear can prevent costly repairs and downtime. Look for any signs of damage on the Worm Gear, Worm Wheel, and Worm Shaft. Pay attention to unusual noises or vibrations during operation, as these can indicate wear or misalignment. Early detection of wear on the Worm Screw can allow for timely replacements or adjustments, ensuring the longevity and reliability of the gear system. Implement a routine check-up schedule to monitor the condition of these components and replace damaged parts as necessary.

- Alignment Checks: Proper alignment of the Magnetic Worm Gear system is vital for its longevity. Misalignment can cause additional stress on the Worm Gear and Worm Wheel, leading to accelerated wear and potential failure. Regularly check the alignment of the Worm Shaft and ensure that it is correctly positioned. Use alignment tools or indicators to assess if adjustments are needed. Keeping the gears properly aligned minimizes wear and enhances the overall functionality of the system, allowing for smoother operation and longer service life.

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in various mechanical systems, providing high torque in a compact design. Selecting the right supplier for worm gears is essential to ensure reliability and performance in your applications. GBC is proud to be the sales agent for Ever-power Group in Australia, establishing ourselves as one of the leading suppliers and manufacturers of worm gears in the region.

Our product range includes Magnetic Worm Gears, which are designed for precision and efficiency. These gears are ideal for applications requiring controlled movement and high torque transmission, making them suitable for both industrial and consumer products.

At GBC, we pride ourselves on our strength in manufacturing and our commitment to outstanding customer service. Our team is dedicated to providing tailored solutions that meet the specific needs of our clients, ensuring satisfaction and long-term partnerships.

Additional information

| Edited | Sylvia |

|---|

The Magnetic Worm Gear is a precision mechanical component designed to provide efficient power transmission. It consists of a worm gear that meshes with a worm wheel, allowing for high torque and reduced speed applications. Typically made from durable materials like aluminum or high-strength plastics, the worm shaft and worm screw are engineered to minimize friction and enhance performance. This gear system is widely used in robotics, automotive, and industrial machinery for its reliability and compact design.