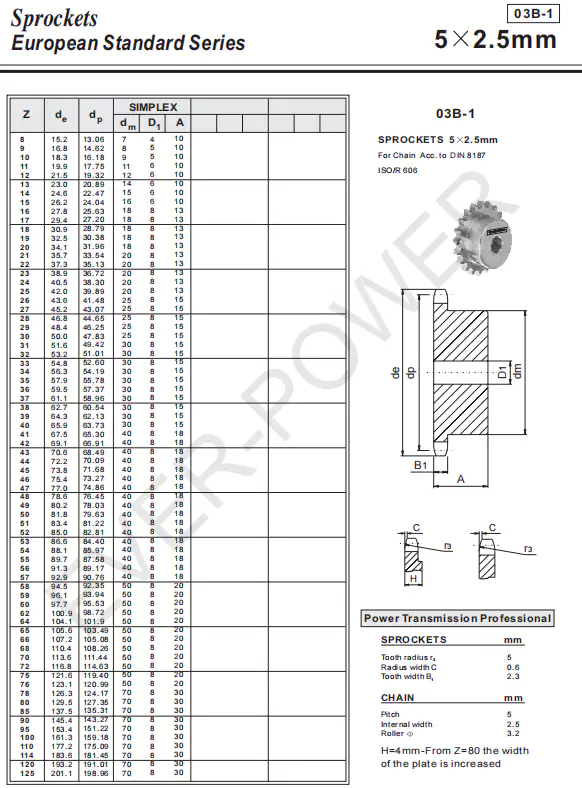

Metric Bore Sprocket for ISO 03B Roller Chain (5mm Pitch)

The Metric Bore Sprocket is designed specifically for ISO 606 and DIN 8187 03B roller chains, featuring a 5mm pitch for precise performance. This durable sprocket ensures reliable operation in various applications, enhancing efficiency and longevity. GBC proudly offers high-quality Metric Bore Sprockets in Australia, ensuring superior performance and customer satisfaction.

Specifications for Metric Bore Sprocket for ISO 03B Roller Chain (5mm Pitch)

A metric bore sprocket designed for the ISO 03B roller chain (5mm pitch) is a crucial mechanical component for transferring rotary motion between two shafts. These sprockets are particularly suited to applications where gears may not be the ideal solution due to constraints of speed, power, or available space. Characterized by their toothed wheels that mesh effectively with compatible chains or toothed belts, these sprockets are instrumental in facilitating torque and power transmission in various machinery.

Basic Structure and Customization

The construction of a metric bore sprocket typically comprises a hub with a predetermined center bore, a series of teeth that encircle its perimeter, and sometimes additional features like a keyway or set screw to ensure a secure attachment to the shaft. Customizing a sprocket involves numerous considerations that impact its performance, including:

- Material: Metric bore sprockets can be manufactured from high carbon steel, alloy steel, or stainless steel, depending on the specific requirements of the application and the environmental factors involved.

- Tooth Profile: Different tooth profiles are available to ensure compatibility with various chain types, allowing for optimal performance in any given setup.

- Number of Teeth: The total number of teeth affects the gear ratio of the system, making this a critical design consideration based on the operational demands.

- Dimensions: Sprockets come in various sizes and dimensions, tailored to meet the specific application requirements, ensuring an effective fit with other components.

- Center Bore: The center bore must be accurately aligned with the shaft size for effective engagement; a mismatch can lead to performance issues.

- Keyway: When necessary, a keyway can be integrated into the design to enhance the connection between the sprocket and the shaft.

- Surface Treatment: Surface coatings can be applied to improve resistance against corrosion and wear, extending the lifespan of the sprocket under operational stresses.

Materials and Manufacturing Process

Our metric bore sprockets are crafted from premium materials such as high carbon steel, alloy steel, or stainless steel, tailored to meet the demands of various applications. The manufacturing process consists of several key steps:

- Material Selection: Choosing the right material is vital, as it directly affects the sprocket's performance and durability under specific operational conditions.

- Cutting and Stamping: Precision tools are used to cut and stamp the sprocket, ensuring accurate dimensions and a suitable tooth profile.

- Machining: Further machining is performed to achieve the final shape and precise dimensions required for effective operation.

- Heat Treatment: A heat treatment process is employed to enhance the hardness and overall durability of the sprocket, allowing it to withstand rigorous use.

- Surface Hardening: Additional surface hardening may be performed to bolster the wear resistance of the sprocket, enhancing its longevity.

- Surface Treatment: The sprocket undergoes surface treatments that improve its corrosion resistance, ensuring reliable performance over time.

- Quality Control: Each manufactured sprocket is subjected to rigorous testing to guarantee that it meets all necessary specifications and performance criteria.

5mm Bore Sprocket Applications

Metric bore sprockets are versatile and find applications across various industries, including:

- Heavy Machinery and Equipment: These sprockets are integral to heavy machinery such as excavators, cranes, and bulldozers where reliable power transmission is essential.

- Food Processing and Packaging: In food processing lines, sprockets are crucial where hygiene and cleanliness are paramount, ensuring safe operation.

- Chemical and Pharmaceutical: Sprockets are utilized in chemical and pharmaceutical applications where resilience against corrosion and harsh chemicals is critical to maintaining functionality.

- Assembly Lines: They play a vital role in assembly lines, helping transmit power efficiently between different machines and conveyor systems.

- Logistics and Warehousing: In logistics and warehousing scenarios, sprockets are essential components of conveyor systems, facilitating smooth operation in material handling.

Maintenance and Troubleshooting of 5mm Bore Sprocket

To ensure the longevity and reliability of any sprocket system, regular maintenance and effective troubleshooting are essential. Important maintenance practices include:

- Daily Inspection: Conduct regular inspections of the sprocket and chain to identify any signs of wear or damage that could impair performance.

- Cleaning: Regular cleaning of the sprocket and chain is vital to prevent the accumulation of dirt and debris that can lead to operational inefficiencies.

- Lubrication: Adequate lubrication of the chain and sprocket is crucial in minimizing wear and prolonging the life of these components.

- Adjustment and Calibration: Proper adjustment of chain tension and calibration of the sprocket ensures correct alignment and secure engagement in the system.

Common issues that can arise in sprocket systems include:

- Skipping Teeth: Often caused by worn teeth, loose chains, or insufficient tension, which can disrupt the operational flow.

- Fracture: This issue can result from fatigue or overload, potentially leading to catastrophic failure if not addressed promptly.

- Wear: Wear and tear are normal with use, but excessive wear can lead to performance degradation and should be monitored closely.

- Noise: Unusual noises can indicate worn teeth or loose chains, signaling the need for immediate inspection.

- Chain Disengagement: Loose chains or damaged teeth can result in disengagement, which can halt operations and necessitate quick repair.

Addressing these problems through diligent troubleshooting and maintenance ensures the continued efficacy of the sprocket system.

Other Types of Sprockets

In addition to metric bore sprockets, we provide a range of other sprocket types, including:

- Platewheel Sprocket: Sprockets designed with a flat, plate-like design for specific applications.

- Idler Sprocket: These sprockets guide the chain or belt without being connected to a power source.

- QD Sprocket: Featuring a quick disconnect mechanism, these sprockets allow for rapid installation and removal.

- Taper Lock Sprocket: These sprockets incorporate a tapered bore design that can be secured with a bushing, providing stability and ease of use.

Our metric bore sprockets are engineered to operate seamlessly with our extensive range of chains, delivering reliable and efficient power transmission solutions for various applications.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we pride ourselves on being one of the best sprocket suppliers in Australia. We specialize in a wide range of sprockets, including the Metric Bore Sprocket for ISO 03B Roller Chain (5mm Pitch). Our sprockets are manufactured with the highest quality standards, ensuring durability and performance in various applications.

At GBC, we understand the importance of exceptional customer service. Our dedicated pre-sales and after-sales support teams are ready to assist you with any inquiries or concerns, ensuring a seamless experience from selection to installation. Furthermore, we offer the flexibility to provide non-standard customizations to meet our customers' specific requirements.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket is designed specifically for ISO 606 and DIN 8187 03B roller chains, featuring a 5mm pitch for precise performance. This durable sprocket ensures reliable operation in various applications, enhancing efficiency and longevity. GBC proudly offers high-quality Metric Bore Sprockets in Australia, ensuring superior performance and customer satisfaction.