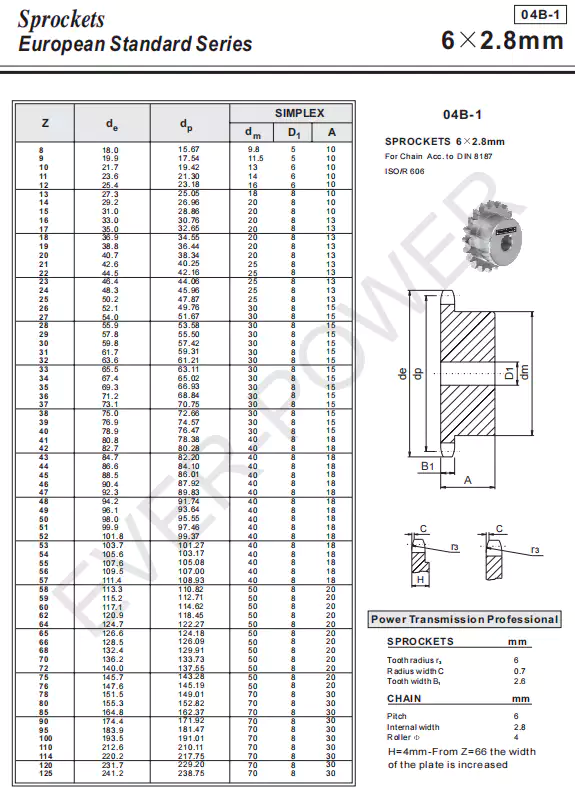

Metric Bore Sprocket for ISO 04B Roller Chain (6mm Pitch)

The Metric Bore Sprocket for ISO 606 and DIN 8187 04B Roller Chain is designed for optimal performance and durability. With a 6mm pitch, it ensures precise fit and efficient operation in various applications. Our company, GBC, provides high-quality sprockets in Australia, ensuring reliability and excellence in every product.

Specifications: Metric Bore Sprocket for ISO 04B Roller Chain (6mm Pitch)

A metric bore sprocket is a critical mechanical component designed to facilitate the transfer of power and motion between rotating shafts by utilizing a chain. This type of sprocket is particularly prevalent in industrial machinery and equipment, serving various applications across different sectors. The Metric Bore Sprocket for ISO 04B Roller Chain (6mm Pitch) meets the ISO 04B standard, ensuring compatibility and reliability in operation.

Basic Structure and Customization of Sprockets

The construction of a metric bore sprocket includes several key elements: teeth or cogs that mesh with the chain, a central bore that fits onto the shaft, and a keyway or key slot to ensure proper alignment with the shaft. Customizing these sprockets involves several vital considerations:

- Material: Common materials for sprockets are high carbon steel, alloy steel, and stainless steel. The choice of material is influenced by the environmental conditions, load requirements, and speed of the application.

- Tooth Profile: The design of the tooth profile is crucial as it affects how the sprocket interacts with the chain, influencing the efficiency and smoothness of power transmission.

- Number of Teeth: The tooth count is essential as it determines the speed ratio between the driving and driven shafts, impacting overall performance.

- Dimensions: Dimensions, like pitch diameter, outer diameter, and thickness, must align with the chain size and specific application needs.

- Center Bore: This is the hole at the center, crucial for fitting onto the shaft. It requires precise sizing and keying to prevent slippage or misalignment.

- Keyway: The keyway facilitates torque transmission between the sprocket and shaft, which is essential for effective operation.

- Surface Treatment: Applying surface treatments like heat treatment, hardening, and coatings can significantly improve the sprocket's durability and resistance to wear and corrosion.

Materials and Processes Used in Our 6mm Bore Sprockets

We prioritize the use of high-quality materials in our sprockets, combining them with a series of advanced manufacturing processes to ensure optimal performance and reliability. The materials we offer include:

- High Carbon Steel: Known for being cost-efficient, this material provides adequate wear resistance and strength, ideal for moderate to high load applications.

- Alloy Steel: With greater strength and toughness than high carbon steel, alloy steel can handle higher loads and speeds, making it suitable for heavy-duty applications.

- Stainless Steel: This material is renowned for its corrosion resistance, making it perfect for harsh environments or applications where hygiene is paramount.

Our production processes encompass:

- Material Selection and Cutting: We meticulously choose materials based on application requirements and apply advanced cutting tools for precision.

- Forging or Stamping: Utilizing these techniques to form the sprocket teeth ensures high accuracy and strength.

- Machining: CNC machining and lathe work enable us to achieve the exact dimensions and tolerances needed.

- Heat Treatment: This process enhances the hardness and toughness of the sprocket through controlled heating and cooling.

- Surface Treatment: Various methods, including nitriding and zinc plating, are employed to enhance wear and corrosion resistance.

- Quality Check: We conduct comprehensive quality assessments throughout production to guarantee adherence to standards.

Applications of Metric Bore Sprockets

Metric bore sprockets find extensive use across a variety of industries, including:

- Heavy Machinery and Equipment: They are integral to cranes, excavators, and bulldozers, helping transmit power and motion efficiently.

- Food Processing and Packaging: Stainless steel sprockets are vital in food-related equipment, where hygiene and corrosion resistance is critical.

- Chemical and Pharmaceutical: These sprockets are also employed in processing equipment where durability against corrosion and harsh substances is necessary.

- Assembly Lines: Sprockets facilitate the movement of products along assembly lines, enhancing productivity.

- Logistics and Warehousing: They are used in conveyor systems, assisting in the transport of goods within storage facilities.

Maintenance and Troubleshooting of Sprockets

Regular maintenance and inspection are crucial for prolonging the lifespan and ensuring the performance of sprockets. Here are some essential maintenance tips:

- Daily Inspection: Examine the sprocket for wear, damage, or misalignment. Check chain tension and alignment regularly.

- Cleaning: Regularly cleanse the sprocket using appropriate tools to eliminate dirt, debris, and rust, thereby preventing corrosion.

- Lubrication: Use suitable lubricants to reduce friction and wear, ensuring compatibility with the material and operational environment.

- Adjustment and Calibration: Regularly adjust chain tension and alignment to maintain smooth operation and calibrate the sprocket for optimal performance.

Common issues with sprockets include:

- Jumping Teeth: Often due to loose chain tension or worn teeth; adjustments or replacements may be necessary.

- Broken Teeth: Caused by excessive loads or impacts; replacing the sprocket or reducing the load is advisable.

- Wear: Normal wear can happen over time, necessitating replacement if it exceeds acceptable limits.

- Noise: Misalignment or lack of lubrication may cause excessive noise; identifying the root cause is essential.

- Chain Slippage: Often results from loose tension or worn teeth, requiring tension adjustments or replacement.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, recognized as one of the best sprocket suppliers in Australia. We specialize in high-quality sprockets, including our Metric Bore Sprocket for ISO 04B Roller Chain with a 6mm pitch. Our sprockets are crafted from premium materials, ensuring durability and reliability in various applications.

At GBC, we pride ourselves on our exceptional pre-sales and after-sales services. Our knowledgeable team is dedicated to assisting customers in selecting the right products to meet their specific needs. We are committed to providing support throughout the purchasing process and beyond, ensuring complete satisfaction with our products.

Additionally, we offer non-standard customizations based on client requirements, allowing us to meet unique specifications effectively. Partner with GBC for top-notch sprockets tailored to your needs.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket for ISO 606 and DIN 8187 04B Roller Chain is designed for optimal performance and durability. With a 6mm pitch, it ensures precise fit and efficient operation in various applications. Our company, GBC, provides high-quality sprockets in Australia, ensuring reliability and excellence in every product.