Metric Bore Sprocket for ISO 28B Roller Chain (44.45mm Pitch)

The Metric Bore Sprocket is designed for use with ISO 606 and DIN 8187 28B roller chains, featuring a precise 44.45mm pitch. This durable sprocket ensures optimal performance and longevity in various applications, making it a reliable choice for your machinery needs. GBC offers high-quality Metric Bore Sprockets in Australia.

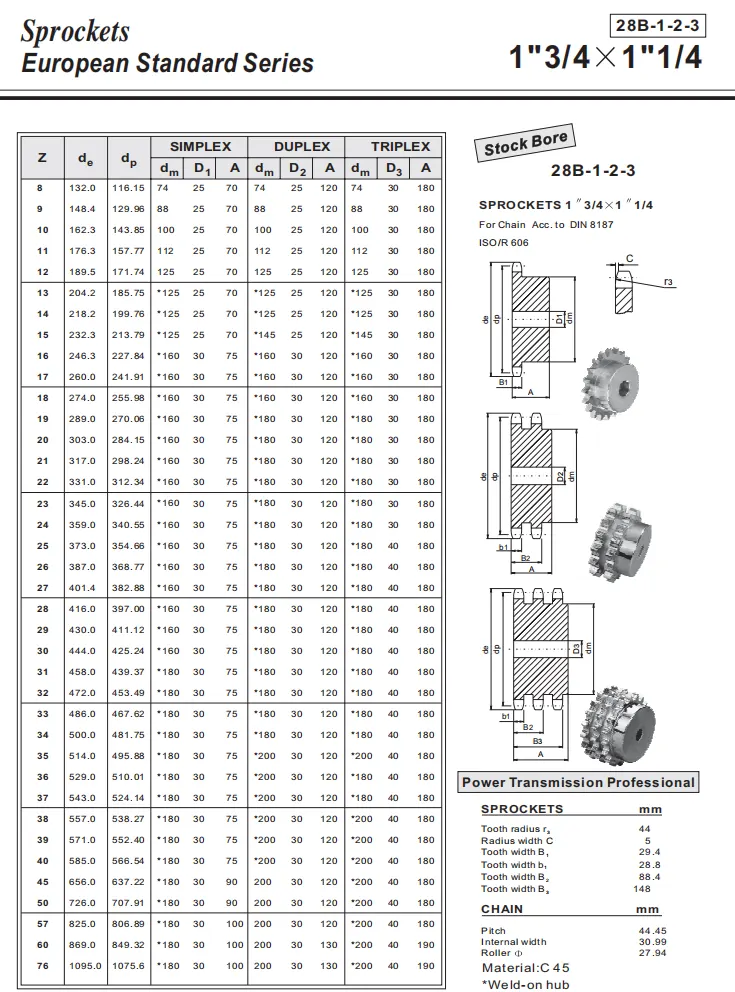

Specifications of Metric Bore Sprocket for ISO 28B Roller Chain (44.45mm Pitch)

A metric bore sprocket is a crucial mechanical device that facilitates the transfer of rotational force between components through a chain. This type of sprocket plays a vital role in numerous industrial machines and applications. The metric bore sprocket is specifically designed with a standard bore size that aligns with a designated metric shaft size. The Metric Bore Sprocket for ISO 28B Roller Chain features 28 teeth, a 44.45mm pitch, and a bore size that is ideal for various operational needs.

Basic Structure of Sprocket

The primary components of a sprocket include its teeth, bore size, pitch, and keyway. The teeth interlock with the chain to effectively transfer power while ensuring that the chain remains securely in place to prevent slipping. When customizing a sprocket, important features such as material, tooth profile, teeth count, dimensions, bore size, keyway, and surface treatment must be carefully considered to meet specific application requirements. Each aspect contributes to the overall effectiveness and efficiency of the sprocket in its intended use.

Material and Manufacturing Process

The Metric Bore Sprocket for ISO 28B Roller Chain is typically constructed from high-carbon or alloy steel, or stainless steel, which provides the necessary strength and durability. The manufacturing process encompasses several stages, including material selection, cutting, punching, forging, machining, heat treatment, surface hardening, rust prevention, and rigorous quality control measures to ensure the final product meets industry standards.

- Material Selection: High-quality steel is selected for its superior durability and resistance to wear.

- Cutting: The raw material is accurately cut to the required dimensions for subsequent processes.

- Punching: The initial shape of the sprocket is formed through a precise punching process.

- Forging: This process enhances the sprocket's strength and toughness through effective shaping techniques.

- Machining: High-precision machining ensures the sprocket meets exact specifications for performance.

- Heat Treatment: The sprocket undergoes heat treatment to achieve improved hardness and wear resistance.

- Surface Hardening: Hardening the surface enhances the sprocket's durability against wear and corrosion.

- Rust Prevention: Application of rust-resistant coatings mitigates the risk of corrosion.

- Quality Control: Each sprocket is subjected to strict testing protocols to verify its quality and functionality.

Applications

Widely recognized for its versatility, the Metric Bore Sprocket for ISO 28B Roller Chain is utilized across various industries like heavy machinery, food processing, pharmaceuticals, assembly lines, logistics, and warehousing. Its design accommodates applications that demand high-precision and robust power transmission, making it an indispensable component for reliable operational performance.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of the sprocket, regular maintenance is essential. Here are key maintenance practices to follow:

- Daily Inspection: Conduct daily checks for any visible signs of damage or wear to the sprocket.

- Cleaning: It is critical to clean the sprocket periodically to eliminate dirt and debris that may cause damage.

- Lubrication: Frequent lubrication helps reduce friction and protects against wear and corrosion.

- Adjustment and Calibration: Proper adjustments should be made to ensure the sprocket operates efficiently.

Some common issues that may arise include jumping teeth, breakage, excessive wear, unusual noise, and chain slippage. Practical solutions for these problems include:

- Jumping Teeth: Adjust chain tension or consider replacing the chain if necessary.

- Breakage: Replace any broken sprockets promptly with new components.

- Wear: Inspect and replace worn sprockets or chains to maintain performance.

- Excessive Noise: Lubricate the sprocket or replace it based on inspection findings.

- Chain Slippage: Verify chain tension and adjust as needed to ensure proper engagement.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, recognized as one of the best sprocket suppliers in Australia. We specialize in providing high-quality metric bore sprockets tailored for ISO 28B roller chains (44.45mm pitch). Our sprockets are manufactured with precision engineering, ensuring durability and outstanding performance in various applications.

At GBC, we pride ourselves not only on the quality of our products but also on our comprehensive pre-sales and after-sales services. Our knowledgeable team is always ready to assist you in selecting the right sprockets for your needs and providing support throughout the entire purchasing process. We are committed to ensuring customer satisfaction and offering solutions that exceed expectations.

Additionally, we understand that every application is unique, which is why we offer non-standard customization options based on customer requirements. You can trust GBC for all your sprocket needs.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket is designed for use with ISO 606 and DIN 8187 28B roller chains, featuring a precise 44.45mm pitch. This durable sprocket ensures optimal performance and longevity in various applications, making it a reliable choice for your machinery needs. GBC offers high-quality Metric Bore Sprockets in Australia.