Motor Grader Chain

GBC motor grader chains are available in a variety of models with clear specifications. They have significant advantages, including high-strength structure to adapt to harsh working conditions, surface hardening to improve wear resistance, and modular design for easy maintenance. They are manufactured using advanced materials and precision processes to ensure excellent performance. They are widely used in mining and other fields to improve efficiency and ensure safety.

GBC Motor Grader Chain Specifications

The following table clearly presents the core technical parameters of GBC Motor Grader Chain.

| Product Model | Pitch (mm) | Minimum Load (kN) | Average Load (kN) |

|---|---|---|---|

| HD816 | 25.40 | 8700 | 10000 |

| HD820 | 31.75 | 12900 | 14800 |

| HD824 | 38.10 | 17400 | 20000 |

| HD828 | 44.45 | 22600 | 26000 |

| HD832 | 50.80 | 28700 | 33000 |

| HD840 | 63.50 | 53000 | 61000 |

| HD848 | 76.20 | 81800 | 94000 |

Key Benefits

GBC Motor Grader Chain incorporates several key technical advantages to ensure outstanding performance in harsh environments:

- High-strength structure: Ensures stable operation under harsh conditions. This structural design enables it to withstand the huge impacts and continuous loads common on Australian construction and mining sites, thereby reducing the risk of unexpected failures.

- Surface hardening: Significantly improves wear resistance and extends service life. In Australia's abrasive soil and mineral environment, chain wear is a major challenge. Through advanced surface hardening, GBC Chain can effectively resist wear, ensure longer service life, reduce replacement frequency and operating costs.

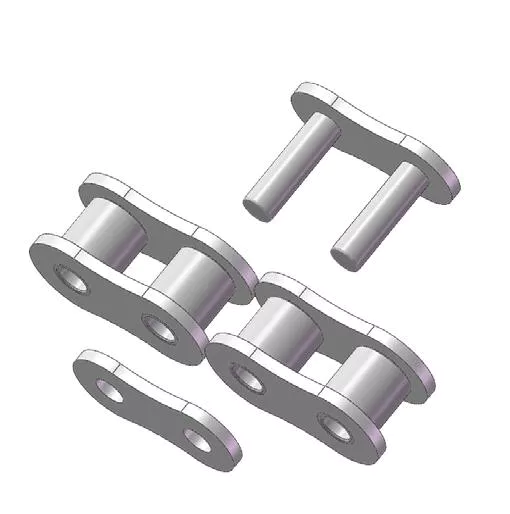

- Modular link design: Greatly facilitates installation, removal and maintenance. In the field of heavy machinery, downtime means huge economic losses. The modular design simplifies the on-site maintenance process, allowing technicians to inspect, replace or repair the chain faster, thereby minimizing equipment downtime and improving operating efficiency.

These technical features directly translate into practical benefits, such as reduced equipment downtime, extended equipment life and reduced maintenance costs in harsh working conditions. GBC Motor Grader Chain is a solution that delivers tangible economic benefits to customers.

Design Principle and Function of Grader Chain

As a high-strength transmission chain, the core function of the grader chain is to transmit power and drive the key components of the grader, such as the blade and crawler system. In the operation of the grader, the performance of the chain directly affects the overall efficiency and accuracy of the equipment. The grader is regarded as a precision tool that can achieve "millimeter-level accuracy" leveling operations. The quality and design of the chain directly determine whether the grader can accurately complete tasks such as road leveling and site leveling. If the strength, wear resistance and impact resistance of the chain are insufficient, the grader cannot effectively transmit power, resulting in unstable blade operation, reduced leveling accuracy, and even failure under heavy load. Therefore, the grader chain is not just a simple component, it is also a key driving factor for the grader to achieve its core function - precise leveling and efficient operation. The excellent performance of the chain directly ensures that the grader can maintain stable, efficient and precise operation under various complex working conditions, thereby improving the quality and progress of the entire project.

Advanced Materials & Precision Manufacturing

The superior performance of GBC Motor Grader Chains is the result of careful selection of advanced materials and strict control of precision manufacturing processes. Heavy-duty industrial chains are often made of high-grade alloy steels, such as chrome-molybdenum steel or nickel-chrome steel, which are known for their superior strength, hardness and wear resistance. These materials are selected to ensure that the chain can withstand the rigors of extreme loads and abrasive environments.

The manufacturing process of GBC Chain strictly follows a number of precision processes, and each link reflects the ultimate pursuit of quality:

- Raw Material Sourcing: The manufacturing process begins with a strict selection of high-quality steel bars, ensuring that all raw materials are sourced from reputable suppliers. This is the cornerstone of the chain's strength and durability.

- Wire Drawing: The steel bars are pickled to remove impurities and oxide scale, and then precisely drawn to the required wire diameter. This process transforms the steel bars into high-strength wire, ready for subsequent link forming.

- Link Forming: The wire is fed into a forming machine, where it is straightened, punched and bent to form open links. The newly formed link is pushed precisely into the previous link and fully closed, gradually building up the chain's structure.

- Precision welding: The chain automatically rotates as it approaches the welding position, ensuring that the weld is applied precisely to the notched area of the chain, thereby achieving maximum weld strength. After welding, burrs are trimmed to give the chain a smooth surface.

- Calibration: On the calibration machine, the chain is stretched to its final, precise length. The applied tension is typically 2.2 times the strength required for its specified grade, which ensures the consistency and strength of the chain's dimensions and verifies its tensile properties.

- Advanced heat treatment: This is a crucial step in chain manufacturing. The chain is heated by an induction coil and then water quenched and tempered. This induction heat treatment process ensures that each link is hardened consistently and reliably, significantly improving the chain's strength, hardness, wear resistance and impact resistance.

Motor Grader Chains for Mining/Quarrying

| Industry Sector | Specific Applications | Core Benefits (Chain Support) |

|---|---|---|

| Mining and Quarrying | Construction and Maintenance of Transport Roads | Ensure safe and efficient operation of trucks, reduce equipment maintenance/fuel/tire costs |

| Surface Mining and Earthmoving | Optimize the working environment, improve the efficiency of mining fleets, and reduce downtime | |

| Path Preparation and Maintenance in Open-Pit Mines | Maintain a flat working surface, control dust, and enhance safety and productivity | |

| Quarry Operations | Withstand high wear and impact, ensuring equipment reliability in harsh environments |

Troubleshooting Common Grader Chain Problems

Even the highest quality grader chains can experience some common problems over long periods of heavy duty operation. Understanding the causes of these problems and initial troubleshooting steps can help operators respond quickly and minimize downtime. GBC is committed to providing comprehensive support to help customers solve these challenges.

| Fault Type | Possible Causes | Preliminary Inspections |

|---|---|---|

| Excessive Wear | Insufficient lubrication, improper chain tension, sprocket wear, abrasive environment, or mismatched chain selection | Check the lubrication condition, adjust the chain tension, and inspect whether the sprocket tooth profile is normal |

| Chain Breakage | Overload, excessive impact load, material fatigue, manufacturing defects (extremely rare in GBC chains), or long-term wear without timely replacement | Check for abnormal impacts or overload operations, and examine the fracture nature of the broken chain link (fatigue fracture or brittle fracture) |

| Abnormal Noise | Insufficient lubrication, misalignment between the chain and sprocket, improper chain tension, damaged chain links, or foreign object jamming | Check lubrication, alignment, and tension, and inspect the chain for jammed or damaged links |

| Chain Tooth Skipping or Falling Off | Severely worn sprockets, excessive chain elongation, insufficient tension, or mismatched chain and sprocket models | Check whether the sprocket tooth profile is severely worn (e.g., in a "shark fin" shape), and measure whether the chain pitch is excessively elongated |

Why Choose GBC?

As Ever-power's sales agent in Australia, GBC is able to ensure that Australian customers have access to excellent products that are in sync with international standards.

GBC is deeply rooted in the Australian market and is committed to providing localized professional services and timely technical support. This is in stark contrast to some general international suppliers, which may not be able to provide the same level of localized response and support. Through this localization strategy, GBC is able to better understand the unique needs and operational challenges of Australian customers and provide customized solutions. It provides customers with dual guarantees of product quality and after-sales service.

Customer Testimonials

The real experience of customers is the most powerful proof of the quality of GBC products and services. The following are the positive feedbacks from GBC customers on GBC grader chains and services in different regions and application scenarios in Australia.

| Feedback from a major mining contractor in the Pilbara region of Western Australia: “At our mines in the Pilbara, we face some of the harshest abrasive environments on earth every day. Our motor grader chains are subject to tremendous stress and wear. Since switching to GBC motor grader chains, we have noticed a significant improvement in chain wear life. In the past, we would have had to replace our chains more frequently, resulting in expensive downtime. Now, GBC chains are performing exceptionally well in these extreme conditions, reducing the frequency of replacements and saving us significant maintenance costs. This reliability is critical to the continued efficient operation of our mines.” |

| Feedback from a regional civil engineering company in Sydney, New South Wales: “As a company focused on urban infrastructure, we are very sensitive to equipment downtime. GBC We were impressed by the modular design of the grader chain. The installation process is faster and simpler than the chains we used before, and routine maintenance has become more convenient. This means that our graders can be put into use faster, reducing the risk of project delays. This easy maintenance feature directly helps us improve overall construction efficiency and ensure that projects are delivered on time. ” |

| Feedback from a large agricultural enterprise in rural Victoria:

“On our farm, graders are used to level land and maintain farm roads, and these operations are often carried out on rugged and uneven ground. We found that GBC grader chains can maintain excellent performance even under continuous impact and heavy loads. Its high-strength structure and impact resistance ensure the stability of the chain in various complex terrains, reducing the risk of accidental breakage. This allows our graders to reliably complete critical land leveling operations and greatly improve agricultural productivity. ” |

| Feedback from a government road maintenance department in Brisbane, Queensland:

“We are responsible for maintaining a large number of public roads in Queensland and have high requirements for the reliability of grader chains and supplier support. GBC The local support provided is very responsive, and no matter what technical problems we encounter, their expert team can always provide professional guidance and solutions. This timely and localized support is crucial to ensure the continuity of our road maintenance work and help us improve the quality of public infrastructure. ” |

| Feedback from an equipment rental company in Adelaide, South Australia:

"As an equipment rental company, the graders we rent often operate in various harsh working conditions for different customers. Therefore, the durability of the chain is key for us. The durability of GBC grader chains exceeds our expectations, and performs well even under frequently changing working environments and high-intensity use. This not only reduces our maintenance and replacement costs, but more importantly, improves the overall reliability of our rental equipment, thereby improving customer satisfaction and bringing us more repeat customers." |

These customer testimonials together depict the excellent performance of GBC grader chains in the Australian market, from the durability and easy maintenance of the product itself to the professional service and localized support of the GBC team, fully demonstrating how GBC creates real value for customers and builds deep trust.

GBC motor grader chains are available in a variety of models with clear specifications. They have significant advantages, including high-strength structure to adapt to harsh working conditions, surface hardening to improve wear resistance, and modular design for easy maintenance. They are manufactured using advanced materials and precision processes to ensure excellent performance. They are widely used in mining and other fields to improve efficiency and ensure safety.