Multi Stage Telescopic Hydraulic Cylinder

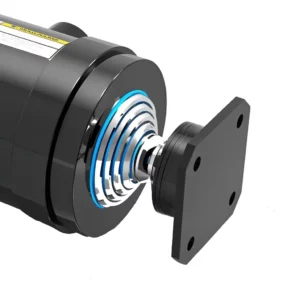

A multistage telescopic hydraulic cylinder is another form of a telescopic hydraulic cylinder with a multistage telescopic piston rod, usually consisting of three, four or more stages. It is composed of a plurality of piston hydraulic cylinders, and the piston rod of each piston cylinder is the cylinder of the next piston cylinder. Compact structure, small space, but the work trip can be very long. Multistage retractable hydraulic cylinders are often used in construction machinery and other walking machinery, such as cranes, dump cars and other hydraulic systems. It is also suitable for occasions where the installation space is limited but the working stroke is required to be longer, such as the telescopic arm of the ladder fire truck and the telescopic arm of the ladder crane.

Multi Stage Telescopic Hydraulic Cylinder Specifications

| MODEL | STAGES | STROK mm |

PIVOTS 48° mm |

CAPACITY tonne |

VOLUME litres |

WEIGHT kg |

L | A | B | C | D | E | F | H | I |

| mm | |||||||||||||||

| Telescopic Hydraulic Cylinder | 4 | 510 | 630 | 3.9 | 1.5 | 13 | 337 | 145 | 192 | 73 | 120 | 58 | 40 | 95 | 120 |

| 4 | 810 | 1000 | 2.7 | 1.9 | 18 | 350 | 155 | 195 | 100 | 85 | 45 | 35 | 95 | 115 | |

| 4 | 820 | 1010 | 4.8 | 3.1 | 19 | 358 | 156 | 202 | 100 | 85 | 43 | 40 | 110 | 148 | |

| 6 | 1000 | 1230 | 4.3 | 4.1 | 19 | 332 | 153 | 169 | 95 | 85 | 43 | 40 | 125 | 148 | |

| 5 | 1030 | 1270 | 5.8 | 4.9 | 23 | 361 | 152 | 209 | 95 | 85 | 43 | 40 | 125 | 148 | |

| 5 | 1250 | 1540 | 5.8 | 6 | 28 | 406 | 152 | 254 | 95 | 85 | 43 | 40 | 125 | 148 | |

| 5 | 1440 | 1780 | 5.8 | 6.9 | 29 | 446 | 152 | 294 | 95 | 85 | 43 | 40 | 125 | 148 | |

| 4 | 1490 | 1840 | 7.3 | 8.3 | 35 | 547 | 156 | 391 | 83 | 120 | 58 | 40 | 125 | 148 | |

| 4 | 1690 | 2090 | 7.3 | 9.4 | 48 | 597 | 156 | 441 | 83 | 120 | 58 | 40 | 125 | 148 | |

| 4 | 1960 | 2420 | 7.3 | 11 | 55 | 672 | 155 | 517 | 82 | 120 | 43 | 40 | 125 | 148 | |

| 5 | 2120 | 2620 | 5.8 | 10.1 | 58 | 581 | 148 | 433 | 91 | 85 | 43 | 40 | 125 | 148 | |

| 5 | 2450 | 3020 | 508 | 11.8 | 61 | 656 | 148 | 508 | 91 | 85 | 43 | 40 | 125 | 148 | |

| 5 | 1160 | 1430 | 8.6 | 7.9 | 39 | 415 | 199 | 216 | 125 | 120 | 58 | 45 | 145 | 165 | |

| 5 | 1440 | 1780 | 8.6 | 9.8 | 40 | 475 | 199 | 276 | 125 | 120 | 58 | 45 | 145 | 165 | |

| 6 | 1420 | 1750 | 6.9 | 8.5 | 32 | 404 | 183 | 221 | 125 | 85 | 43 | 45 | 145 | 165 | |

| 6 | 1730 | 2140 | 6.9 | 10.2 | 38 | 459 | 157 | 302 | 99 | 85 | 43 | 45 | 145 | 165 | |

| 5 | 2140 | 2640 | 8.6 | 17.3 | 66 | 615 | 162 | 453 | 88 | 120 | 58 | 45 | 145 | 165 | |

| 5 | 2480 | 3060 | 8.6 | 16.9 | 84 | 690 | 162 | 528 | 88 | 120 | 58 | 50 | 145 | 171 | |

| 6 | 2980 | 3680 | 6.9 | 17.7 | tba | 674 | 155 | 519 | 97 | 85 | 43 | 45 | 145 | 165 | |

| 6 | 1750 | 2160 | 14 | 19 | 72 | 533 | 254 | 279 | 138 | 150 | 73 | 210 | 177 | 216 | |

| 7 | 1580 | 1950 | 11 | 15 | 61 | 419 | 154 | 265 | 145 | 120 | 58 | 210 | 177 | 216 | |

| 6 | 2930 | 3620 | 22 | 44 | 114 | 689 | 245 | 444 | 162 | 150 | 73 | 230 | 198 | 238 | |

| 8 | 1820 | 2250 | 13 | 21 | 77 | 424 | 219 | 205 | 145 | 120 | 58 | 230 | 198 | 238 | |

| MODEL | STAGES | STROK mm |

CAPACITY tonne |

VOLUME litres |

WEIGHT kg |

L | A | B | C | D | E | F | H | I |

| mm | ||||||||||||||

| Telescopic Hydraulic Cylinder | 2 | 600 | 5 | 2.2 | 20 | 469 | 418 | 30 | 365 | 55 | 31 | 40 | 95 | 125 |

| 2 | 800 | 5 | 3.3 | 26 | 566 | 515 | 30 | 470 | 55 | 31 | 40 | 95 | 125 | |

| 3 | 850 | 3.9 | 2.5 | 19 | 454 | 403 | 30 | 350 | 40 | 31 | 40 | 95 | 125 | |

| 3 | 1140 | 8.9 | 7.4 | 34 | 545 | 490 | 30 | 454 | 55 | 31 | 40 | 125 | 158 | |

| 3 | 1470 | 8.9 | 9.5 | 58 | 677 | 623 | 30 | 569 | 55 | 31 | 40 | 125 | 158 | |

| 4 | 1140 | 7.3 | 6.3 | 30 | 464 | 413 | 30 | 359 | 55 | 31 | 40 | 125 | 158 | |

| 4 | 1280 | 7.3 | 7.1 | 34 | 485 | 434 | 30 | 395 | 55 | 31 | 40 | 125 | 158 | |

| 4 | 1480 | 7.3 | 8.2 | 33 | 549 | 498 | 30 | 444 | 55 | 31 | 40 | 125 | 158 | |

| 4 | 1680 | 7.3 | 9.3 | 48 | 588 | 567 | 30 | 494 | 55 | 31 | 40 | 125 | 158 | |

| 5 | 2240 | 8.6 | 15.2 | 58 | 643 | 568 | 40 | 521 | 55 | 31 | 40 | 125 | 178 | |

Multi Stage Telescopic Hydraulic Cylinder Introduction

Our Multi-Stage Telescopic Hydraulic Cylinders are precisely engineered and built to withstand the toughest working conditions. Here are some of the key features that make them stand out:

- Multi-Stage Design: These cylinders consist of multiple stages that collapse within each other, allowing for a significantly longer stroke length compared to traditional single-stage cylinders. This design offers a compact solution while maintaining high force capabilities.

- High Load Capacity: GBC's telescopic hydraulic cylinders are constructed to handle heavy loads. Their robust design and high-quality materials ensure durability and reliable performance, even in demanding applications.

- Customizable Stroke Length: We understand that every project is unique. That's why we offer a wide range of stroke lengths and sizes, allowing you to choose the perfect cylinder to meet your specific requirements.

- Precision Engineering: Our cylinders are manufactured to exacting standards, ensuring smooth operation and minimal friction. This precision contributes to the longevity of the product and reduces maintenance costs.

- Sealed for Protection: To prevent contamination and maintain hydraulic fluid integrity, our telescopic cylinders come with effective sealing mechanisms, ensuring a longer service life.

- Corrosion Resistance: GBC utilizes high-quality materials and finishes that are resistant to corrosion, making the hydraulic cylinders suitable for use in harsh environments.

- Ease of Installation: These cylinders are designed with ease of installation in mind. Mounting options are versatile, and our team can provide guidance to ensure a hassle-free setup.

Applications of Multi Stage Hydraulic Cylinder

Our Multi-Stage Telescopic Hydraulic Cylinders are utilized across various industries due to their versatility and dependability. Common applications include:

- Construction: Telescopic cylinders are frequently found in construction machinery like cranes, excavators, and backhoes, providing precise control over boom and bucket movements.

- Material Handling: These cylinders are perfect for forklifts, aerial work platforms, and conveyor systems, enabling smooth and controlled lifting and tilting actions.

- Agriculture: In farming equipment such as front-end loaders and hay balers, telescopic cylinders enhance the efficiency of agricultural tasks.

- Waste Management: Garbage trucks employ telescopic hydraulic cylinders to effectively lift and empty heavy waste containers.

- Fire and Rescue: In firefighting equipment, telescopic cylinders are crucial for ensuring stable ladder extensions and precise nozzle positioning.

- Manufacturing: These cylinders are used in manufacturing processes for accurate positioning and automation operations.

- Oil and Gas: In offshore drilling equipment, telescopic cylinders support the safe and efficient extraction of oil and gas resources.

How to Choose the Right Telescopic Hydraulic Cylinder?

Selecting the appropriate telescopic hydraulic cylinder is essential for your project¡¯s success. Consider the following factors:

- Load Capacity: Assess the maximum load required for your application and ensure the chosen cylinder can handle it efficiently.

- Stroke Length: Determine the necessary stroke length, factoring in any potential variations during operation.

- Mounting Options: Evaluate how the cylinder will be mounted to ensure compatibility with your equipment.

- Environment: Consider the environmental conditions in which the cylinder will work, as some applications may need resistance to dust, water, or extreme temperatures.

- Maintenance: Reflect on maintenance needs, as some cylinders may require more regular upkeep than others.

- Cost: While budget is a consideration, investing in a higher-quality cylinder can lead to long-term savings through reduced maintenance and downtime.

At GBC, our knowledgeable team is ready to assist you in selecting the ideal telescopic hydraulic cylinder for your requirements. We provide personalized recommendations and expert advice to ensure the success of your project.

Benefits of Choosing Telescopic Hydraulic Cylinders from Us

By choosing GBC as your hydraulic technology partner, you unlock numerous benefits:

- Quality Assurance: We emphasize quality in every aspect of our products, from design to manufacturing, ensuring you receive dependable and long-lasting solutions.

- Customization: Recognizing that one size does not suit all, our team collaborates with you to customize our products to meet your specific needs.

- Global Reach: With a worldwide footprint, we can deliver our products and support customers globally.

- Expertise: Our team consists of industry experts with extensive experience in hydraulic technology, always ready to share knowledge and provide support.

- Customer Support: Our dedication to customer satisfaction extends beyond the sale. We offer exceptional customer support and quick responses to inquiries and technical issues.

- Competitive Pricing: We aim to provide competitive pricing without sacrificing quality, making our products accessible to a broad customer base.

Additional information

| Edited by | Sylvia |

|---|

A multistage telescopic hydraulic cylinder is another form of a telescopic hydraulic cylinder with a multistage telescopic piston rod, usually consisting of three, four or more stages. It is composed of a plurality of piston hydraulic cylinders, and the piston rod of each piston cylinder is the cylinder of the next piston cylinder. Compact structure, small space, but the work trip can be very long. Multistage retractable hydraulic cylinders are often used in construction machinery and other walking machinery, such as cranes, dump cars and other hydraulic systems. It is also suitable for occasions where the installation space is limited but the working stroke is required to be longer, such as the telescopic arm of the ladder fire truck and the telescopic arm of the ladder crane.

Telescopic Hydraulic Cylinders Review

Peter Grayson, Maintenance Supervisor

We’ve been using telescopic hydraulic cylinders in our heavy-duty loaders for over a year. The multi-stage extension works smoothly, and the compact design fits perfectly in tight spaces. We’ve noticed consistent pressure distribution, which reduces wear on seals. Maintenance is straightforward, though we had a minor leak once due to debris buildup—easily fixed with a quick clean. Overall, they’ve improved our uptime significantly.