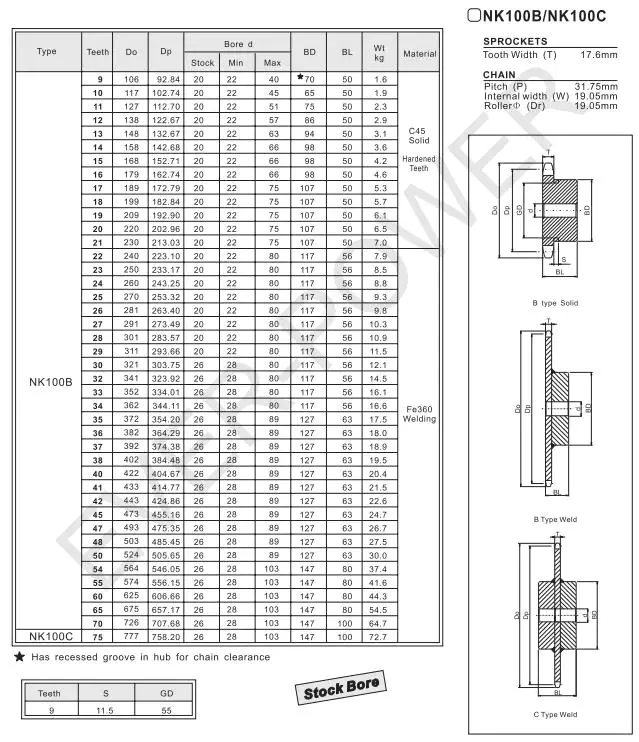

Plain Bore Sprocket NK100B/NK100C (31.75mm Pitch)

The Plain Bore Sprocket NK100B/NK100C features a 31.75mm pitch, designed for durability and performance in various applications. Its robust construction ensures reliable operation, making it an ideal choice for machinery and conveyor systems. GBC proudly supplies high-quality Plain Bore Sprockets in Australia, ensuring customers receive top-notch products.

Specifications of Plain Bore Sprocket NK100B/NK100C (31.75mm Pitch)

A plain bore sprocket is a specific type of sprocket commonly employed in various industrial contexts. Unlike other sprockets that may feature specialized fittings, the plain bore design focuses on a straightforward approach to transmitting rotational motion between shafts using a chain. The design includes teeth that effectively engage the chain, facilitating efficient power transfer and motion execution.

Basic Structure of a Sprocket

- Material: Sprockets are typically crafted from high carbon steel, alloy steel, or stainless steel, tailored to meet distinct application needs.

- Tooth profile: The configuration of the teeth is essential as it influences the interaction between the sprocket and the chain, which is crucial for performance.

- Number of teeth: The count of teeth plays a significant role in determining the gear ratio, which subsequently impacts the speed and torque characteristics of the system.

- Size: The overall dimensions, including diameter and width, are critical in ensuring compatibility with the intended application.

- Bore: The center hole is designed to fit onto the shaft securely, ensuring effective motion transfer.

- Keyway: A slot is often cut into the bore to accommodate a key, which prevents any unwanted rotation of the sprocket on the shaft.

- Surface treatment: Various treatments, such as rust prevention, can be applied to enhance durability and performance, thereby extending the lifespan of the sprocket.

Materials and Processes Used in Sprockets

Our sprockets are manufactured with a commitment to high-quality materials and advanced production techniques. The materials available include high carbon steel, alloy steel, and stainless steel, specifically selected based on the application requirements. The manufacturing process involves careful material selection followed by cutting, stamping or forging, machining (which includes turning, milling, and drilling), heat treatment methods like quenching and tempering, surface treatments for rust prevention, and thorough quality testing to ensure performance standards are met.

Applications of Sprockets

Sprockets are versatile components utilized in a variety of industries, including:

- Heavy machinery and equipment, where precise motion control is crucial

- Food processing and packaging, ensuring smooth operation in production lines

- Chemical and pharmaceutical sectors, where reliability is paramount

- Assembly lines, where efficient motion transfer directly affects productivity

- Logistics and warehousing, facilitating smooth operations in material handling

Maintenance and Upkeep of Sprockets

To guarantee the longevity and optimal performance of sprockets, adhering to proper maintenance practices is essential. This includes:

- Conducting daily inspections to identify any signs of wear or damage promptly

- Regularly cleaning the sprocket to eliminate dirt and debris, which can hinder performance

- Lubricating both the sprocket and chain to minimize friction and enhance efficiency

- Making necessary adjustments and calibrations to the sprocket as needed, ensuring it operates within specifications

Common issues that may occur with sprockets include teeth skipping, breakage, wear, excessive noise, and chain disengagement. Here are some solutions to these problems:

- For teeth skipping, check alignment and tension of the chain for corrections.

- If breakage occurs, replacing the damaged sprocket with a new one is necessary.

- Wear can often be mitigated through consistent maintenance and lubrication efforts.

- Reducing excessive noise is achievable by ensuring proper lubrication and alignment.

- In cases of chain disengagement, inspect for wear or damage and make essential adjustments.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are recognized as one of the best sprocket suppliers in Australia. Our extensive range includes the Plain Bore Sprocket NK100B/NK100C with a 31.75mm pitch. We take pride in our high-quality sprockets that are manufactured to meet rigorous industry standards, ensuring durability and reliability for our customers.

Our commitment to exceptional customer service extends beyond the sale, as we offer comprehensive pre-sales consultancy and dedicated after-sales support. We understand the importance of finding the right product for your specific needs, and our knowledgeable team is always ready to assist you in making informed decisions.

Additionally, we offer non-standard customization options to meet our clients' unique requirements, ensuring that you get exactly what you need for your applications.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK100B/NK100C features a 31.75mm pitch, designed for durability and performance in various applications. Its robust construction ensures reliable operation, making it an ideal choice for machinery and conveyor systems. GBC proudly supplies high-quality Plain Bore Sprockets in Australia, ensuring customers receive top-notch products.