Plain Bore Sprocket NK120-2B/NK120-2C (38.1mm Pitch)

The Plain Bore Sprocket NK120-2B/NK120-2C, featuring a 38.1mm pitch, is designed for durability and optimal performance in various applications. Its robust construction ensures a reliable solution for power transmission needs. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, meeting the industry’s stringent standards.

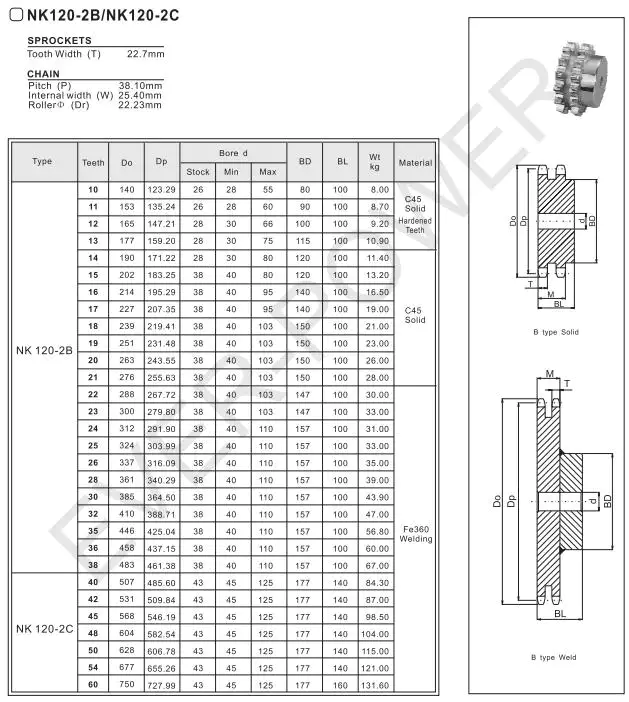

Specifications: Plain Bore Sprocket NK120-2B/NK120-2C (38.1mm Pitch)

A standard bore sprocket serves as a vital component in various mechanical systems, specifically designed to transmit rotational motion between multiple shafts utilizing a chain. These sprockets are integral in numerous applications, facilitating efficient power transfer and motion in an array of machinery.

Basic structure and customization of sprockets

Materials

When customizing a sprocket, selecting the appropriate material is crucial for performance and durability. The most commonly used materials include high carbon steel, alloy steel, and stainless steel. Each material is chosen based on specific application requirements, environmental conditions, and the expected load and wear characteristics of the sprocket.

Tooth profile and number of teeth

The tooth profile and the number of teeth on a sprocket are critical factors that influence its overall performance. Different tooth profiles can provide varying efficiencies and levels of engagement with the chain. Additionally, the total number of teeth impacts the speed ratio and torque transmission, which are essential for achieving the desired operational outcomes.

Dimensions

Accurate dimensions of a sprocket—including outer diameter and thickness—are necessary to ensure a proper fit and alignment within the mechanical system. Incorrect dimensions can lead to operational inefficiencies, misalignment, and increased wear, making precise measurements essential during the design and manufacturing process.

Keyway and bore

The keyway and bore of a sprocket are vital for securing the sprocket onto the shaft. The keyway features a slot that accommodates a key, preventing rotational slippage, while the bore ensures a stable and secure fit for mounting. Proper attention to these features enhances the reliability and efficiency of the sprocket in operation.

Surface treatments

To improve durability and resistance to corrosion, various surface treatments can be applied to sprockets. Techniques include heat treatment, quenching, tempering, surface hardening, and rust protection. These treatments not only enhance the lifespan of the sprocket but also maintain its performance under varying operational conditions.

Materials and processes used in our sprockets

Materials

Our sprockets are crafted from high carbon steel, alloy steel, or stainless steel, each providing exceptional strength, wear resistance, and corrosion resistance. These materials are selected based on their suitability for specific applications, ensuring the sprockets meet the rigorous demands of various industrial settings.

Processes

The manufacturing process for our sprockets involves several steps, including careful material selection, cutting, stamping, forging, and machining processes like turning, milling, and drilling. Heat treatment processes, such as quenching and tempering, ensure the sprockets achieve optimal strength and hardness. Surface treatments for rust prevention and stringent quality testing further guarantee the reliability of our products.

Applications

Heavy machinery and equipment

Sprockets are extensively utilized in heavy machinery and equipment, such as construction machinery, mining equipment, and agricultural machinery. In these applications, sprockets play a crucial role in transmitting power and motion efficiently, ensuring reliable operation in demanding industrial environments.

Food processing and packaging

In the food processing industry, sprockets are integral to conveyor systems that facilitate the movement of food products through various processing stages. They ensure smooth and reliable operation, essential for maintaining efficiency and hygiene in food packaging and handling operations.

Chemical and pharmaceutical

In the chemical and pharmaceutical industries, sprockets are indispensable for conveying materials and managing equipment movement during production processes. Their design offers precise and efficient power transmission, which is critical for maintaining operational integrity in these sensitive and regulated environments.

Assembly lines

Sprockets are essential components of assembly line systems, enabling the synchronized movement of parts and finished products throughout the manufacturing process. Their reliability and performance are key to achieving high efficiency and productivity in assembly operations.

Logistics and warehousing

In logistics and warehousing operations, sprockets facilitate the efficient transport of goods within conveyor systems. Their use ensures smooth transitions and minimizes delays, contributing to streamlined operations and enhanced productivity in supply chain management.

Maintenance and upkeep

Daily inspections

Conducting regular inspections of the sprocket is essential for identifying any signs of wear, damage, or misalignment. Such inspections help prevent potential issues that could impair performance and ensure that the sprocket operates optimally throughout its lifespan.

Cleaning

Maintaining a clean sprocket free from dirt, debris, and lubricant buildup is crucial for ensuring smooth operation. Regular cleaning routines help preserve performance levels and extend the overall lifespan of the sprocket, preventing premature wear and operational inefficiencies.

Lubrication

Proper lubrication of the sprocket and chain is vital for achieving smooth movement and reducing friction. This practice minimizes wear and tear on both components. It is important to apply lubricants in accordance with the manufacturer’s recommendations to ensure optimal performance and longevity.

Adjustment and calibration

Periodic adjustment and calibration of the sprocket's position and tension are necessary for maintaining peak performance. Proper adjustments help avoid issues such as chain slippage or excessive wear, ensuring the system operates smoothly and efficiently.

Common issues and solutions

Tooth skipping

Tooth skipping can occur when there is improper alignment between the sprocket and chain or when teeth are worn or damaged. Regular checks and maintenance of alignment are essential, and if necessary, replacing the sprocket or chain can restore smooth operation.

Breakage

In the event of a broken sprocket, it is crucial to determine the root cause, such as excessive load or material fatigue. Replacing the damaged sprocket promptly, alongside addressing any underlying issues, will help prevent future breakage and ensure the reliability of the system.

Wear

Frequent inspections for signs of wear are vital to maintaining the integrity of the sprocket. If significant wear is detected, it is important to replace the sprocket to avoid further damage to the chain and to ensure effective power transmission throughout the system.

Noise

If excessive noise is produced during sprocket operation, it may indicate misalignment, loose mounting, or worn components. Realigning or tightening the sprocket, along with replacing any excessively worn parts, can help restore quiet and efficient operation.

Chain detachment

Frequent chain detachment from the sprocket often signals issues with tension, alignment, or chain condition. Proper adjustment of tension and replacing the chain if necessary can ensure secure engagement, preventing future detachment during operation.

Plain Bore Sprockets Supplier - GBC

In addition to the Plain Bore Sprocket NK120-2B/NK120-2C (38.1mm Pitch), we also offer a diverse range of sprockets tailored for various applications and requirements. Our selection includes platewheel sprockets, idler sprockets, QD sprockets, taper lock sprockets, and more, ensuring we meet the specific needs of our customers.

GBC is the Australian sales agent for Ever-power Group, and we are one of the best sprocket suppliers in Australia. Our commitment to quality is reflected in our range of sprockets, including the Plain Bore Sprocket NK120-2B/NK120-2C with a 38.1mm pitch. Each sprocket is manufactured using high-grade materials to ensure durability and reliability in various applications.

At GBC, we pride ourselves on offering exceptional pre-sales and after-sales services. Our knowledgeable team is always ready to assist customers in selecting the right sprocket for their needs and providing support long after the purchase. We also understand that each customer may have unique requirements, which is why we offer non-standard customization options tailored to specific requests.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK120-2B/NK120-2C, featuring a 38.1mm pitch, is designed for durability and optimal performance in various applications. Its robust construction ensures a reliable solution for power transmission needs. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, meeting the industry’s stringent standards.