Plain Bore Sprocket NK180B/NK180B (57.15mm Pitch)

The Plain Bore Sprocket NK180B/NK180B features a precise 57.15mm pitch, designed for optimal performance in various applications. Its robust construction ensures durability and reliability, making it an ideal choice for industrial machinery. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, ensuring top-notch performance for our clients.

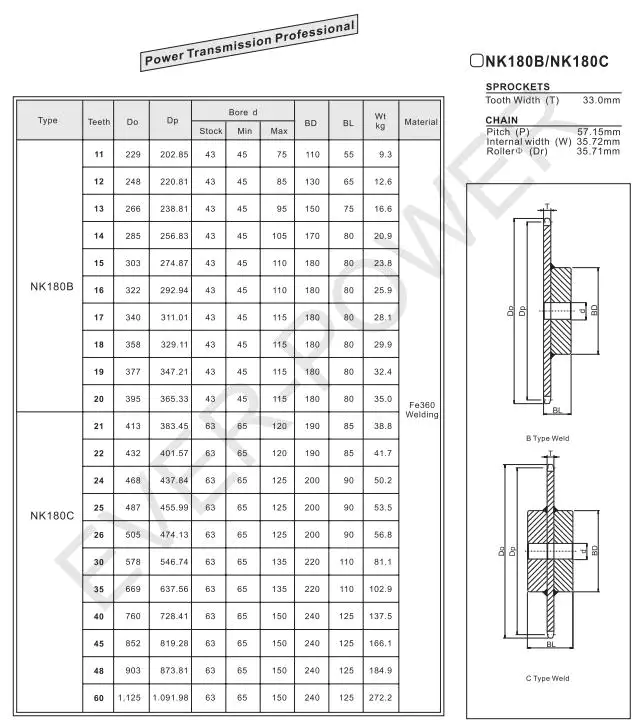

Specifications for Plain Bore Sprocket NK180B/NK180B (57.15mm Pitch)

A plain bore sprocket is an essential component in various mechanical systems, designed with a pre-bored hole to accommodate a specific shaft size. The NK180B model of the plain bore sprocket features a black oxide finish, which provides excellent protection against corrosion, enhancing its durability in demanding environments. Below is a selection table that outlines the various dimensions and specifications of the NK180B sprocket, ensuring it meets the unique requirements of your application.

Basic Structure of Sprockets

The fundamental structure of a sprocket includes essential components such as teeth, a bore, and a hub. The teeth engage with the chain, facilitating power transmission to the connected machinery. The bore is the pre-bored opening that ensures a precise fit onto the shaft, while the hub serves as the attachment point for the sprocket to the equipment. When customizing a sprocket, several factors must be considered for optimal performance:

- Material: Materials can include high carbon steel, alloy steel, or stainless steel, each chosen based on specific application needs.

- Tooth profile: Options for the tooth profile range from standard to non-standard or custom designs, allowing for tailored functionality.

- Number of teeth: The quantity of teeth on the sprocket directly affects the speed ratio, influencing the machinery's performance.

- Dimensions: Accurate dimensions are crucial for compatibility with the equipment utilized.

- Bore diameter: The bore's diameter must precisely match that of the shaft to ensure a secure fit.

- Keyway: The keyway must align with the shaft's keyway for effective power transmission.

- Surface treatment: Surface treatments such as black oxide or zinc plating can enhance corrosion resistance and overall appearance.

Materials and Manufacturing Process

Our plain bore sprockets are constructed from high carbon steel, alloy steel, or stainless steel, selected based on customer specifications. The manufacturing process encompasses several critical steps, including material selection, cutting, punching, forging, CNC machining, heat treatment, surface hardening, surface treatment, and quality inspection, ensuring a durable final product.

- Material selection: We choose materials based on the specific requirements of each application.

- Cutting and punching: The raw material is precisely cut and punched to achieve the desired size and shape.

- Forging: The initial shape of the sprocket is formed through the forging process, enhancing material integrity.

- CNC machining: Precision CNC machining refines the sprocket to its final specifications.

- Heat treatment: A heat treatment phase improves the strength and longevity of the sprocket.

- Surface hardening: Surface hardening techniques are applied to resist wear effectively.

- Surface treatment: The final surface treatment protects against rust while enhancing appearance.

- Quality inspection: Each sprocket undergoes thorough quality inspections to meet industry standards.

Applications

The versatility of our plain bore sprockets allows for their use across various industries, including heavy machinery, food processing, pharmaceuticals, assembly lines, logistics, and warehousing. Their robust design and reliability make them ideal for demanding applications. An illustrative example of our Hunting Tooth Sprockets in a heavy machinery setup can be seen in the image below:

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are vital for the longevity and performance of sprockets. Regularly scheduled maintenance can prevent most issues associated with wear and tear. Key maintenance steps include:

- Daily inspection: It is essential to conduct daily inspections to identify any issues or signs of deterioration early on.

- Cleaning: Keeping sprockets clean helps prevent the accumulation of dirt and debris that can damage both the sprocket and chain.

- Lubrication: Regular lubrication reduces friction, significantly decreasing wear and tear rates.

- Adjustment: Regular adjustments ensure proper alignment and functioning of the sprockets.

Common sprocket problems include skipping teeth, breakage, excessive wear, noise, and chain slippage. Implementing appropriate troubleshooting methods is essential for resolving these issues:

- Skipping teeth: This often arises from worn elements; replacing worn chains or sprockets can rectify the situation.

- Breakage: Often caused by overloading or using inferior materials, upgrading to a high-load capacity sprocket can provide a solution.

- Wearing: Insufficient lubrication or misalignment can lead to wear; regular maintenance is crucial to prevent this.

- Excessive noise: Noise issues may signal misalignment or wear; checking alignment and replacing affected components can help.

- Chain slippage: This may occur from a loose tensioner; tightening or replacing components as needed will resolve this issue.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the best sprocket suppliers in Australia. Our commitment to quality ensures that we provide only the finest products, including the Plain Bore Sprocket NK180B/NK180B with a 57.15mm Pitch. This sprocket is designed for optimal performance and durability, making it a reliable choice for various applications.

At GBC, we prioritize customer satisfaction, offering exceptional pre-sale and after-sale services to assist our clients at every step. Our knowledgeable team is always ready to provide expert guidance and support, ensuring you choose the right sprocket for your needs.

Furthermore, we understand that each customer may have unique requirements; thus, we offer non-standard customizations to meet specific demands. Trust GBC for all your sprocket needs.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK180B/NK180B features a precise 57.15mm pitch, designed for optimal performance in various applications. Its robust construction ensures durability and reliability, making it an ideal choice for industrial machinery. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, ensuring top-notch performance for our clients.