Plain Bore Sprocket NK35B (9.525mm Pitch)

The Plain Bore Sprocket NK35B features a 9.525mm pitch, designed for optimal performance in various mechanical applications. Its robust construction ensures durability and reliability, making it an ideal choice for your machinery needs. GBC proudly provides high-quality NK35B sprockets across Australia, ensuring excellent service and top-notch products.

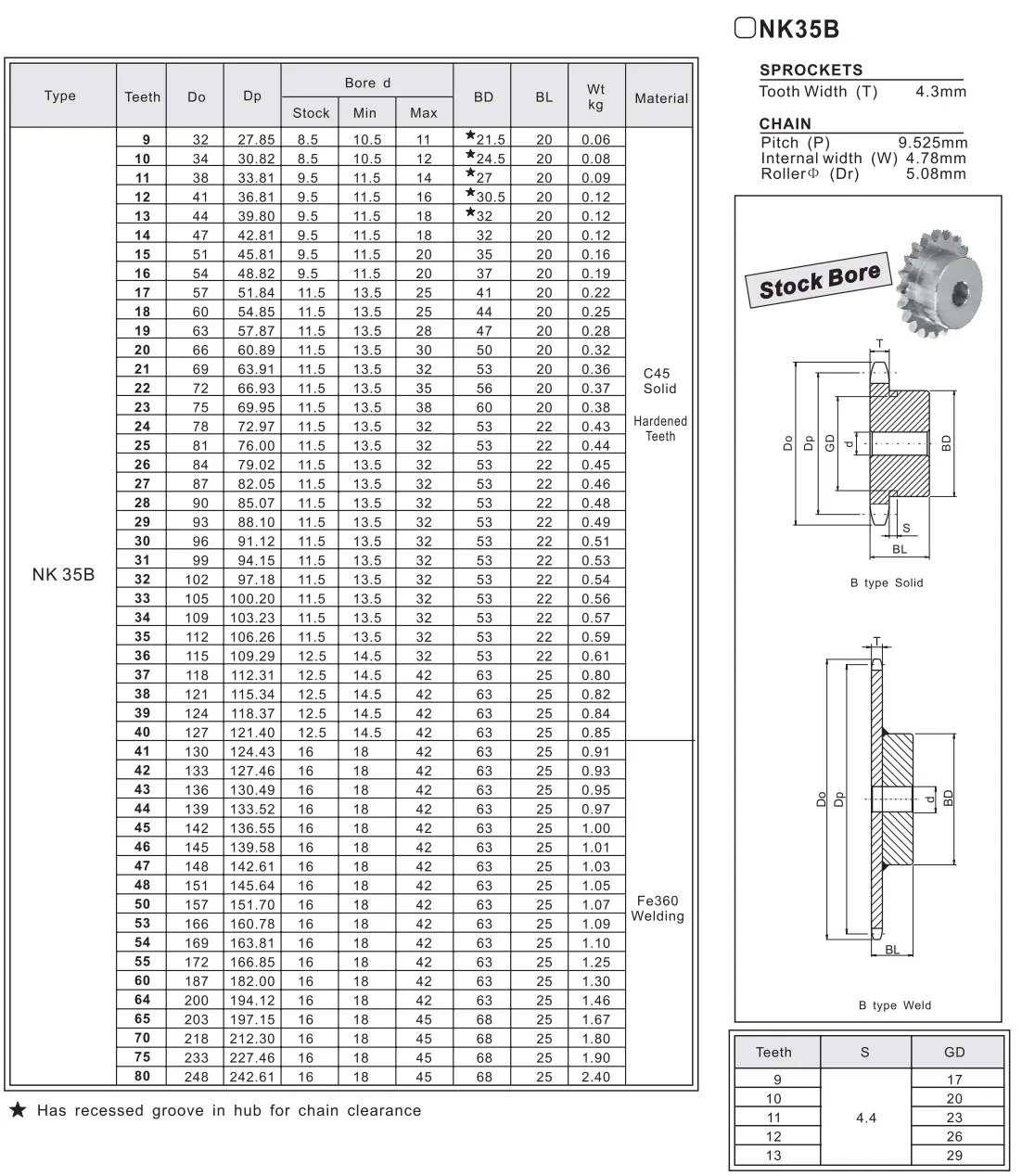

Specifications for Plain Bore Sprocket NK35B (9.525mm Pitch)

A plain bore sprocket is a specialized type of sprocket designed with a pre-bored hole at its center, simplifying the installation process on a shaft without requiring further machining. The Plain Bore Sprocket NK35B exemplifies this design, offering a variety of sizes that range from 9 to 72 teeth. With a pitch measurement of 9.525 mm (0.375 inches), this sprocket is crafted from premium-quality steel, ensuring exceptional durability and strength for demanding applications.

Basic Structure of a Sprocket

The fundamental components of a sprocket include the teeth, pitch diameter, and bore. The teeth play a crucial role in engaging with the chain, transmitting torque efficiently from the shaft to the driven component. The pitch diameter refers to the circle that passes through the center of each tooth, essential for calculating the speed ratio between driving and driven elements. The bore, or pre-bored hole, enables the sprocket to be easily mounted onto a shaft without additional adjustments.

When customizing sprockets, several critical factors emerge, such as the material, tooth profile, number of teeth, overall size, bore specifications, keyway requirements, and surface treatment options. Each factor significantly influences the sprocket's performance, efficiency, and longevity, making it vital to consider these elements during the design process.

Materials and Processes Used in Our Sprockets

Our sprockets are manufactured using high-quality materials, including high-carbon steel, alloy steel, and stainless steel. Each of these materials possesses unique properties, allowing us to customize sprockets that meet the diverse needs of our clients. We employ a variety of manufacturing processes, such as material selection, cutting, stamping, forging, machining, heat treatment, and surface hardening. Quality inspection is integrated into each stage to assure that every sprocket meets the strictest standards of quality and performance.

Applications of Sprockets

Sprockets find applications in numerous industries, including heavy machinery, food processing and packaging, chemical and pharmaceutical sectors, assembly lines, logistics, and warehousing. Each sprocket we design and manufacture is tailored to meet the specific requirements of various applications, ensuring optimal performance and extended service life. Our commitment to quality and innovation means that our sprockets are reliable in challenging operational environments.

Maintenance and Troubleshooting of Sprockets

Proper maintenance and troubleshooting of sprockets are essential for maintaining optimal performance and ensuring longevity. It is recommended to conduct daily checks to identify any signs of wear or damage. Regular cleaning and lubrication will help prevent rust and corrosion. Adjustments should be made as necessary to maintain proper alignment and tension of the chain. Common issues with sprockets include skipping teeth, cracking, wear, excessive noise, and chain slippage, all of which can be resolved through diligent maintenance and timely troubleshooting techniques.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, recognized as one of the top sprocket suppliers in Australia. Our product range includes the Plain Bore Sprocket NK35B, featuring a 9.525mm pitch, which exemplifies the quality and durability we are known for. At GBC, we pride ourselves on providing exceptional pre-sales and after-sales service, ensuring that our customers receive comprehensive support throughout their purchasing journey. Our dedicated team is always ready to assist you with any inquiries and provide expert advice.

Moreover, we understand that every client has unique needs, which is why we offer non-standard customization options based on customer requirements. This flexibility allows us to cater to a wide range of applications, ensuring you find the perfect sprocket solution for your project.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK35B features a 9.525mm pitch, designed for optimal performance in various mechanical applications. Its robust construction ensures durability and reliability, making it an ideal choice for your machinery needs. GBC proudly provides high-quality NK35B sprockets across Australia, ensuring excellent service and top-notch products.