Plate Wheel Sprocket 083B/084B-1

The Plate Wheel Sprocket 083B/084B-1 is designed for durability and performance in various industrial applications. This high-quality sprocket is engineered to provide optimal power transmission and ensure smooth operation in machinery. Its robust construction allows for extended service life and reliability under demanding conditions. GBC proudly offers this premium product in Australia, ensuring top-notch quality for our customers.

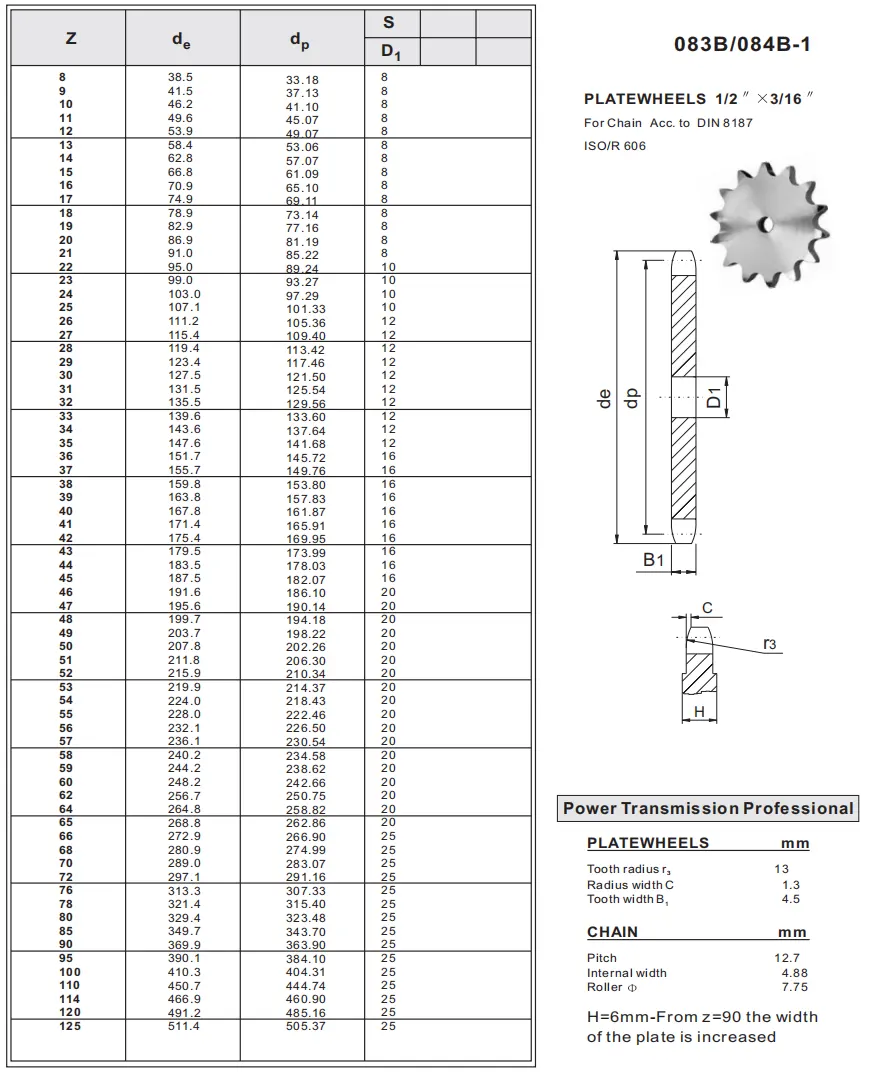

Specifications for Plate Wheel Sprocket 083B/084B-1

Plate Wheel Sprocket 083B/084B-1, widely recognized as a plate sprocket, plays a crucial role in transmission systems. This innovative sprocket design features a collection of flat plates, each equipped with evenly spaced teeth that efficiently engage with a chain. This mechanism effectively transmits power and motion across rotating shafts, ensuring smooth operations in various applications.

Types of Plate Wheels

Plate wheels can be categorized into three distinct types: single row, double row, and multi-row. Each type is designed to meet different performance needs within transmission systems. The selection of the appropriate plate wheel is critical, as it directly influences the efficiency and reliability of power transmission. Understanding the specific requirements of your application will guide you in choosing the right type to ensure optimal functionality.

Product Features

Material Advantages

Platewheel sprockets are designed with several material advantages that enhance their performance and longevity:

- Corrosion resistance to withstand harsh environments

- Wear resistance that ensures a longer lifespan

- Strength and toughness to handle heavy loads and demanding applications

Design Features

The design of platewheel sprockets incorporates several key features that contribute to their effectiveness:

- Lightweight construction for easier handling and installation

- Precision manufacturing that ensures high dimensional accuracy

- Surface treatment techniques that improve durability and performance

Services We Provide

We offer an extensive range of services tailored for platewheel sprockets to meet customer needs:

- Customization based on detailed specifications and provided drawings

- Expert material selection to match specific application requirements

- Advanced surface treatment to enhance product properties

- Effective hardening treatment for increased durability

- Custom packaging solutions to ensure safe delivery

Chainwheel Manufacturing Process

The manufacturing process we employ for chainwheels is meticulous and involves the following steps:

- Forging, which shapes the metal into the desired form

- Machining for achieving precise dimensions

- Hobbing to create the necessary gear teeth

- Teeth heating to enhance hardness

- Treatment on quenching for improved strength

- Surface treatment and rust-proofing to promote longevity

- Quality inspection to ensure that products meet standards

- Packing for protection during transit

- Shipping to deliver products promptly to our customers

Chainwheel Maintenance

Proper maintenance of chainwheels is vital for achieving optimal performance levels. To ensure the longevity and efficiency of your equipment, consider these essential maintenance practices:

- Conduct daily inspections to check for any signs of damage or wear that may compromise functionality

- Engage in regular cleaning to eliminate dirt, debris, and other contaminants that can impair performance

- Apply lubrication to minimize friction, which is crucial for smooth operation

- Timely replacement of worn-out parts to avoid potential breakdowns and maintain system reliability

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the Plate Wheel Sprocket 083B/084B-1, designed to meet various industrial needs with precision and reliability. We take pride in our diverse selection of sprockets and gears, ensuring that our clients have access to high-quality components for their projects.

As a dedicated supplier, we offer exceptional services tailored to our customers' requirements. Not only do we provide standard plate wheel sprockets, but we also specialize in non-standard customization based on client specifications. Our team is ready to assist you in bringing your designs to life, whether through drawings or samples. We invite all customers to reach out for bespoke solutions that fit their unique needs.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket 083B/084B-1 is designed for durability and performance in various industrial applications. This high-quality sprocket is engineered to provide optimal power transmission and ensure smooth operation in machinery. Its robust construction allows for extended service life and reliability under demanding conditions. GBC proudly offers this premium product in Australia, ensuring top-notch quality for our customers.