Plate Wheel Sprocket K100A

The Plate Wheel Sprocket K100A is designed for optimal performance and durability in various applications. Its robust construction ensures longevity, making it an essential component for machinery and vehicles that require reliable power transmission. GBC proudly offers high-quality Plate Wheel Sprockets in Australia, ensuring exceptional performance and reliability.

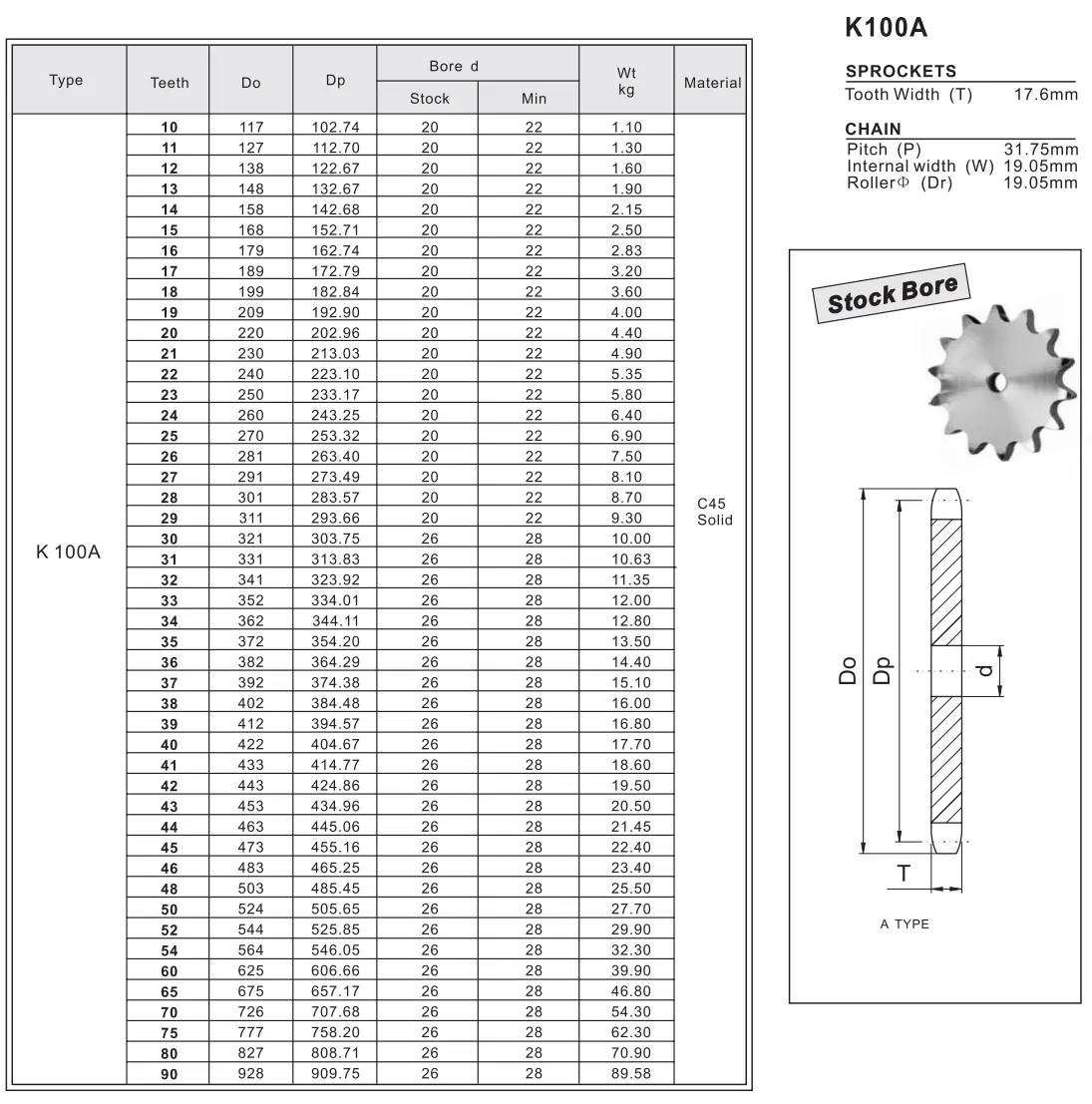

Specifications of Plate Wheel Sprocket K100A

Plate Wheel K100A represents a significant advancement in the realm of sprockets utilized for transmission systems. This sophisticated sprocket serves a vital role in the power transmission mechanism, efficiently establishing a mechanical connection between the driving and driven shafts. Its design and construction are integral to achieving optimal performance in various applications. In this article, we will delve into the essential components and features of the Plate Wheel K100A, shedding light on its functionality and advantages.

Types of Plate Wheel Sprockets

Plate wheel sprockets are categorized into three main types: single-row, double-row, and multi-row. Each category boasts unique designs tailored for specific applications, addressing a variety of transmission requirements. Single-row sprockets are typically utilized in applications where space constraints are a concern, while double-row sprockets provide enhanced load-bearing capabilities. Multi-row sprockets, on the other hand, are ideal for heavy-duty applications that demand high durability and strength. Understanding these classifications can help in choosing the right sprocket for your operational needs.

Product Features of our Plate Wheel Sprockets

Our plate wheel sprockets stand out due to their remarkable material composition and innovative design features, which provide numerous benefits:

- Material Advantages:

- Corrosion resistance: Our sprockets are designed to withstand harsh conditions, ensuring longevity and reliability.

- Wear resistance: The materials used are specifically chosen to resist wear and tear, extending the lifespan of the sprockets.

- Strength and toughness: These sprockets possess high strength-to-weight ratios, making them effective in demanding applications.

- Design Features:

- Lightweight: The design of the K100A minimizes weight without compromising strength, facilitating smoother operation.

- Precision manufacturing: Advanced manufacturing techniques ensure that each sprocket meets stringent quality standards.

- Surface treatment: Our surface treatments enhance the performance and durability of the sprockets.

Services We Provide

We are committed to meeting the diverse needs of our customers through a range of specialized services:

- Customization based on provided drawings: We can tailor the sprockets to fit specific dimension requirements.

- Material selection: Choose from a variety of high-quality materials to suit your application.

- Surface treatment: We provide various treatments to enhance durability and performance.

- Hardening treatment: Our hardening processes improve the wear resistance of the sprockets.

- Customized packaging: Packaging solutions can be tailored to meet your logistical needs.

Chain Wheel Manufacturing Process

The manufacturing process of our chain wheels is meticulously designed to ensure quality and reliability, encompassing several key steps:

- Forging: Initial shaping of the material to enhance strength.

- Machining: Precision machining to achieve exact specifications.

- Hobbing: Cutting the gear teeth to ensure proper engagement.

- Teeth heating: Strengthening the teeth through controlled heating processes.

- Treatment on quenching: Enhancing hardness and durability via quenching techniques.

- Surface treatment/rust-proof treatment: Applying protective coatings to prevent corrosion.

- Quality inspection: Rigorous testing to ensure conformity to standards.

- Packing: Safely packaging the products for transportation.

- Shipping: Efficient dispatch of products to meet customer demands.

Maintenance of Chain Wheels

Proper maintenance of chain wheels is essential for ensuring their durability and effective performance over time. Regular maintenance practices can prevent unexpected failures and extend the operational lifespan of the sprockets. Here are some critical practices to follow:

- Daily inspection: Conducting visual inspections helps identify any signs of wear or damage early on.

- Cleaning: Regular cleaning removes debris and contaminants that could lead to premature wear.

- Lubrication: Adequate lubrication minimizes friction and wear on the sprockets, contributing to smoother operation.

- Replacement: Timely replacement of worn or damaged sprockets is crucial to maintain system efficiency.

Understanding and implementing these maintenance practices can significantly impact the performance and lifespan of your chain wheels, ensuring they operate effectively under various conditions.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top ten gear suppliers in Australia. Our comprehensive range of gear products includes the widely used Plate Wheel Sprocket K100A, which exemplifies our commitment to quality and innovation.

As a leading supplier, we offer a diverse selection of gears tailored to meet various industrial needs. Our products are designed for durability and performance, ensuring that our customers receive the best solutions for their applications. We pride ourselves on our exceptional service, providing expert guidance and support throughout the purchasing process.

In addition to standard offerings, we specialize in custom solutions that cater to our clients' specific requirements. We are not limited to just standard plate wheel sprockets; we welcome customers to bring their designs or samples for bespoke customization. Your unique specifications can become a reality with our dedicated team.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket K100A is designed for optimal performance and durability in various applications. Its robust construction ensures longevity, making it an essential component for machinery and vehicles that require reliable power transmission. GBC proudly offers high-quality Plate Wheel Sprockets in Australia, ensuring exceptional performance and reliability.