Plate Wheel Sprocket K120A

The Plate Wheel Sprocket K120A is designed for durability and performance in various applications. Its robust construction ensures reliability, while the precision engineering guarantees smooth operation. Ideal for industrial machinery and transportation systems, this sprocket enhances efficiency and longevity. GBC proudly supplies high-quality Plate Wheel Sprockets in Australia to meet your needs.

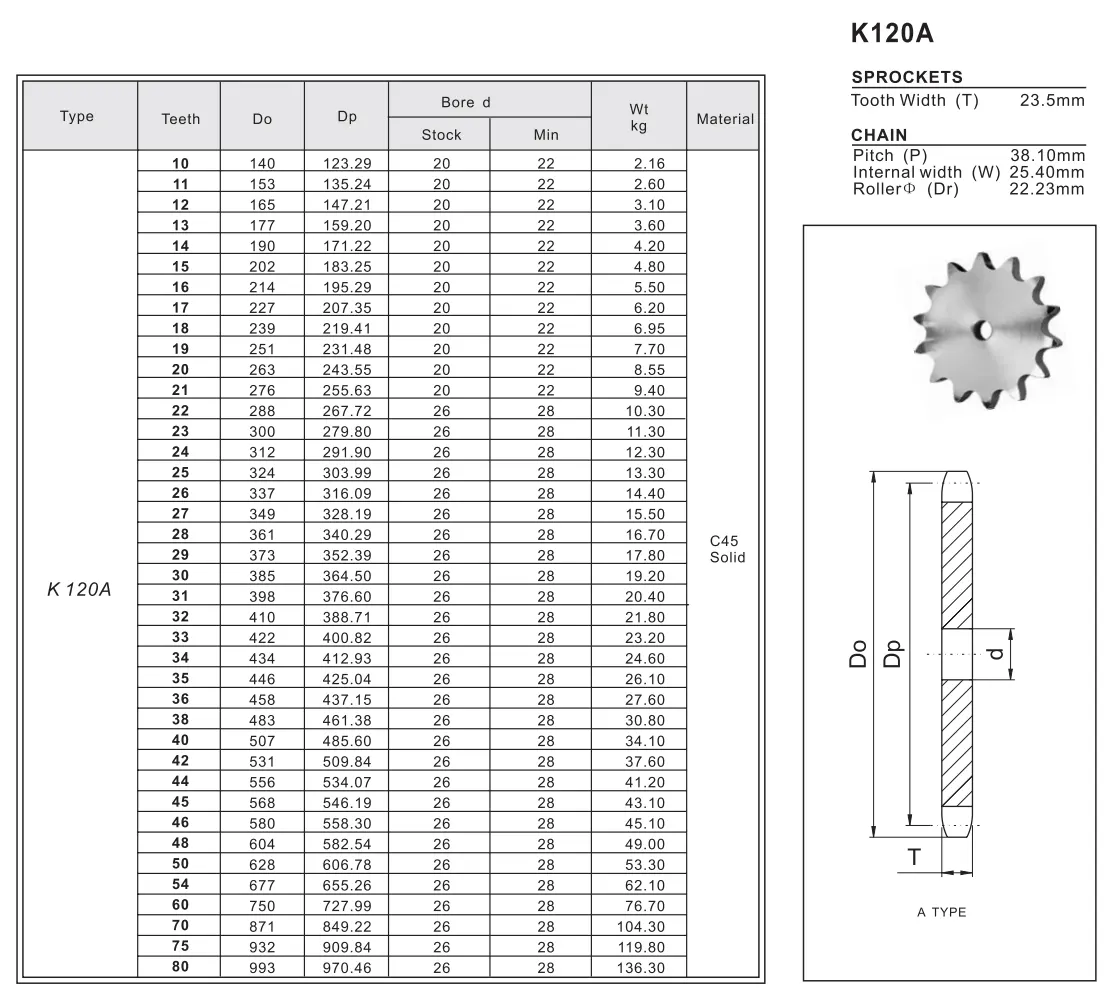

Specifications of Plate Wheel Sprocket K120A

Plate Wheel Sprocket K120A is a unique and highly effective type of plate sprocket extensively utilized in various power transmission systems. Unlike traditional sprockets, the K120A employs plates instead of conventional teeth to engage with the chain, providing a robust and reliable connection. Its fundamental structure includes a hub, several plates, and a bore designed for secure mounting on a shaft, ensuring stability and efficiency during operation.

Types of Plate Wheels

Plate wheels come in several variations, each designed to meet specific operational needs. The three primary types include:

- Single-row plate wheels, which feature only one row of plates, are ideal for applications requiring less torque and simpler engagement.

- Double-row plate wheels consist of two rows of plates arranged in the same plane, with the plates in each row alternating. This configuration enhances torque transmission and durability.

- Multi-row plate wheels are more complex, incorporating multiple rows of plates, each alternating. This design maximizes power transmission and is suitable for more demanding applications.

Product Features of Our Platewheel Sprocket

The platewheel sprockets we offer are distinguished by their superior material and innovative design features:

- Material advantages: Our sprockets are crafted from high-quality materials that exhibit excellent corrosion resistance, wear resistance, strength, and toughness, ensuring longevity and reliability in harsh environments.

- Design advantages: Our sprockets are meticulously designed to be lightweight, precisely manufactured, and subjected to exceptional surface treatments, enhancing their overall performance and aesthetics.

Our Services

We pride ourselves on providing a wide array of services tailored to meet the diverse needs of our customers:

- Customization options allow us to create sprockets based on customer-provided drawings or samples, ensuring that each product meets specific requirements.

- Material selection assistance helps customers choose the most appropriate material for their unique applications, enhancing performance and durability.

- Surface treatment services include various options such as black oxide, electroplating, and powder coating, aimed at improving corrosion resistance and aesthetic appeal.

- Hardening treatment options, including quenching and tempering, are available to enhance the strength and wear resistance of the sprockets.

- Customized packaging services ensure that products are packed and labeled according to individual customer needs, facilitating easy identification and handling.

Our Sprocket Manufacturing Process

Our manufacturing process for sprockets is meticulously designed to guarantee high quality and precision:

- Forging involves shaping raw materials into the desired configuration, ensuring strength and durability.

- Machining takes the rough forgings and processes them to achieve the finished dimensions, leading to a precise fit and function.

- Hobbing is employed to cut the sprocket's teeth using specialized machinery, allowing for accurate and consistent tooth profiles.

- Teeth heating is performed to increase hardness and wear resistance, enhancing the longevity of the sprocket in operational settings.

- Treatment on quenching involves subjecting the sprocket to a special solution to further bolster its hardness and toughness, making it suitable for demanding conditions.

- Surface treatment or rust-proofing enhances corrosion resistance through techniques such as black oxide applications, protecting the sprocket from environmental damage.

- Quality inspection is conducted to verify that each sprocket meets strict specifications, ensuring reliability and performance.

- Packing is carried out according to customer preferences, ensuring safe transport and delivery.

- Shipping concludes the process, with products dispatched to customers in a timely manner.

Maintenance of Plate Wheels

To ensure the longevity and optimal performance of plate wheels, regular maintenance is essential. We recommend the following maintenance steps:

- Daily inspection should be carried out to identify any signs of wear, damage, or misalignment, which can affect performance.

- Cleaning involves removing dirt, grease, and debris from the sprocket and chain, preventing build-up that could lead to operational issues.

- Lubrication is crucial; applying a suitable lubricant to both the sprocket and chain minimizes wear and friction, enhancing their lifespan.

- Replacing worn or damaged components promptly is critical to avoid further damage to the system and to maintain efficient operation.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top ten gear suppliers in Australia. Our extensive product line includes the Plate Wheel Sprocket K120A, which exemplifies our commitment to quality and innovation. We offer a diverse range of gear products that cater to various industrial needs, ensuring that our customers can find the right solution for their applications.

As a dedicated supplier, we prioritize customer satisfaction by providing exceptional service and support. We understand that each business has unique requirements, which is why we offer non-standard customization tailored to our clients' specifications. Our capabilities extend beyond just standard plate wheel sprockets; we invite customers to bring their designs or samples for custom-made solutions.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket K120A is designed for durability and performance in various applications. Its robust construction ensures reliability, while the precision engineering guarantees smooth operation. Ideal for industrial machinery and transportation systems, this sprocket enhances efficiency and longevity. GBC proudly supplies high-quality Plate Wheel Sprockets in Australia to meet your needs.