Plate Wheel Sprocket K200A

Plate Wheel Sprocket K200A

The Plate Wheel Sprocket K200A is designed for optimal performance and durability in various applications. Engineered with precision, it ensures smooth operation and longevity, making it an ideal choice for your machinery needs.

At GBC, we provide high-quality Plate Wheel Sprockets in Australia, ensuring reliable solutions for your industrial requirements.

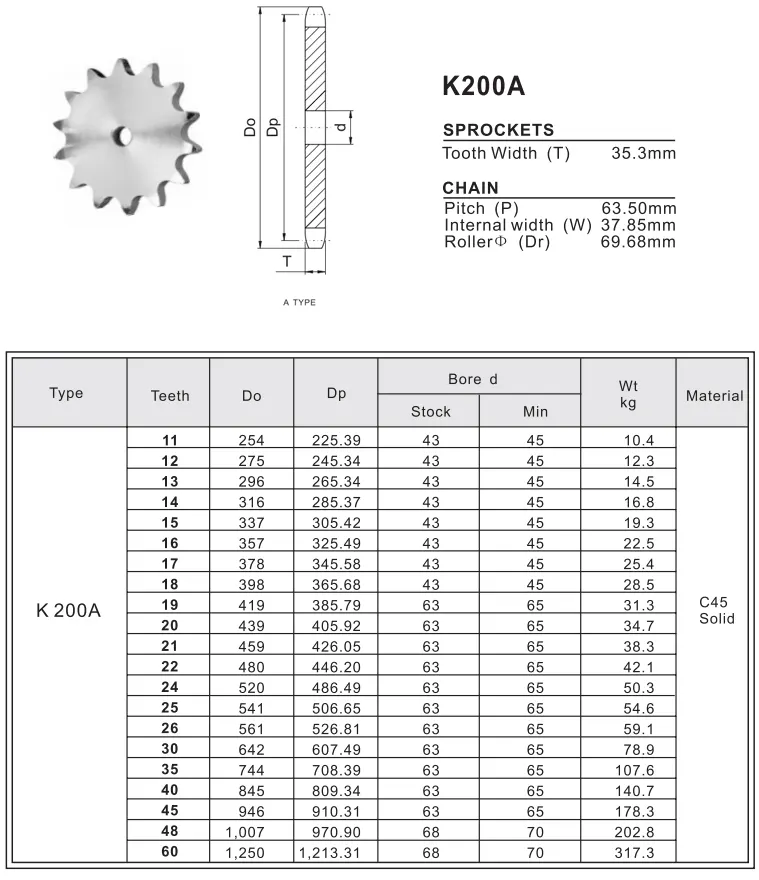

Specifications: Plate Wheel Sprocket K200A

Plate Wheel Sprocket K200A is an advanced component utilized in various power transmission systems. It represents a specific type of flat plate chain wheel, characterized by a circular plate equipped with evenly spaced teeth along its edge. These teeth engage seamlessly with the chain, facilitating the efficient transfer of power from the drive shaft to the driven shaft, ensuring optimal operation in machinery and various applications.

Types of Plate Wheel Sprockets

In the realm of plate wheel sprockets, there are three distinct types to consider: single-row, double-row, and multi-row sprockets. The single-row sprocket finds its place in simpler power transmission setups and is ideal for straightforward applications where minimal complexity is required. In contrast, double-row and multi-row sprockets are engineered for more intricate power transmission requirements, enabling greater efficiency and handling heavier loads, making them suitable for more demanding operational environments.

Product Features of Plate Wheel K200A

Our Plate Wheel K200A sprocket boasts several key features that enhance its performance and reliability:

Material Advantages

- Corrosion resistance: The K200A sprocket is designed to resist rust and various forms of corrosion, which significantly prolongs its lifespan.

- Wear resistance: Constructed from premium materials, this sprocket is highly resistant to wear and tear, ensuring longevity even under high-stress conditions.

- Strength and toughness: The sprocket exhibits exceptional strength and durability, yet maintains the flexibility necessary to endure the operational stresses of power transmission without compromising performance.

Design Features

- Lightweight: Attention to design means the sprocket is lightweight. This attribute reduces the overall weight of the power transmission system, enhancing efficiency.

- Precision manufacturing: Each sprocket is manufactured with precision engineering techniques, guaranteeing accurate dimensions and reliable power transmission.

- Surface treatment: The sprocket benefits from advanced surface treatment processes that boost its resistance to corrosion and enhance overall durability.

Our Services

We provide an array of services catered specifically to the needs of our Plate Wheel K200A sprocket:

Customization

Our customization services empower customers to submit their unique designs and specifications, allowing for tailored solutions that meet specific operational needs.

Material Selection

Customers can choose from a broad spectrum of materials, enabling the selection of the most suitable option for their particular application, enhancing performance and durability.

Surface Treatment

We offer comprehensive surface treatment services aimed at bolstering the sprocket's resistance to corrosion and extending its service life.

Hardening Treatment

To enhance resistance to wear and prolong the sprocket's operational capabilities, we provide effective hardening treatment services.

Customized Packaging

Our customized packaging services are designed to guarantee the safe transit of the sprocket to our customers, protecting it during delivery.

Manufacturing Process of Plate Wheel K200A

The manufacturing process of our Plate Wheel K200A sprockets is meticulously outlined through the following steps:

Forging

The initial step involves forging the sprocket to shape using high-quality materials, ensuring structural integrity from the outset.

Machining

This step entails machining the sprocket for precise dimensional accuracy and a smooth surface finish, which are critical for effective performance.

Hobbing

The sprocket¡¯s teeth are intricately cut using a hobbing machine, a process that ensures their functionality and efficiency.

Teeth Heating

To improve the hardness of the teeth, a heating process is employed, enhancing their durability and performance under load.

Treated on Quenching

The sprocket undergoes a quenching process to bolster its strength and toughness, making it capable of withstanding rigorous operational conditions.

Surface Treatment/Rust-Proof Treatment

The final step includes advanced surface treatment to further enhance corrosion resistance and overall durability.

Quality Inspection

Every sprocket is subjected to a stringent quality inspection process to uphold our high standards of quality assurance.

Packing and Shipping

Finally, the prepared sprockets are packed securely and shipped efficiently to our customers.

Maintenance of Plate Wheel K200A

To maintain the optimal performance and extend the life of the Plate Wheel K200A sprocket, regular maintenance practices are essential:

Daily Inspection

Conduct daily inspections to identify any signs of wear, damage, or misalignment, which can lead to operational issues if not addressed promptly.

Cleaning

Regular cleaning of the sprocket is crucial for removing dirt, debris, and contaminants that could potentially harm its surface and functionality.

Lubrication

Consistent lubrication is key to ensuring smooth and efficient power transmission, minimizing friction and wear during operation.

Replacement

Timely replacement of the sprocket is necessary when signs of wear or damage become apparent, ensuring continued effectiveness in the power transmission system.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the high-quality Plate Wheel Sprocket K200A, designed to meet various industrial applications. As a leading supplier, we offer a diverse selection of gears, ensuring that we cater to the unique needs of our customers across different sectors.

In addition to our standard plate wheel sprockets, we also specialize in non-standard customizations according to client specifications. We encourage customers to bring their designs and samples for tailored solutions that fit their specific requirements. Our dedicated team is committed to providing exceptional service, ensuring that you receive the best products to enhance your operations.

Additional information

| Edited by | Sylvia |

|---|

Plate Wheel Sprocket K200A

The Plate Wheel Sprocket K200A is designed for optimal performance and durability in various applications. Engineered with precision, it ensures smooth operation and longevity, making it an ideal choice for your machinery needs.

At GBC, we provide high-quality Plate Wheel Sprockets in Australia, ensuring reliable solutions for your industrial requirements.