Plate Wheel Sprocket K410A

The Plate Wheel Sprocket K410A is designed for optimal performance in various mechanical applications. Built with durability in mind, it ensures smooth operation and longevity under demanding conditions. Its precision engineering allows for efficient power transmission, making it an essential component for machinery and vehicles. GBC provides high-quality Plate Wheel Sprockets in Australia, ensuring reliability and excellence in every product.

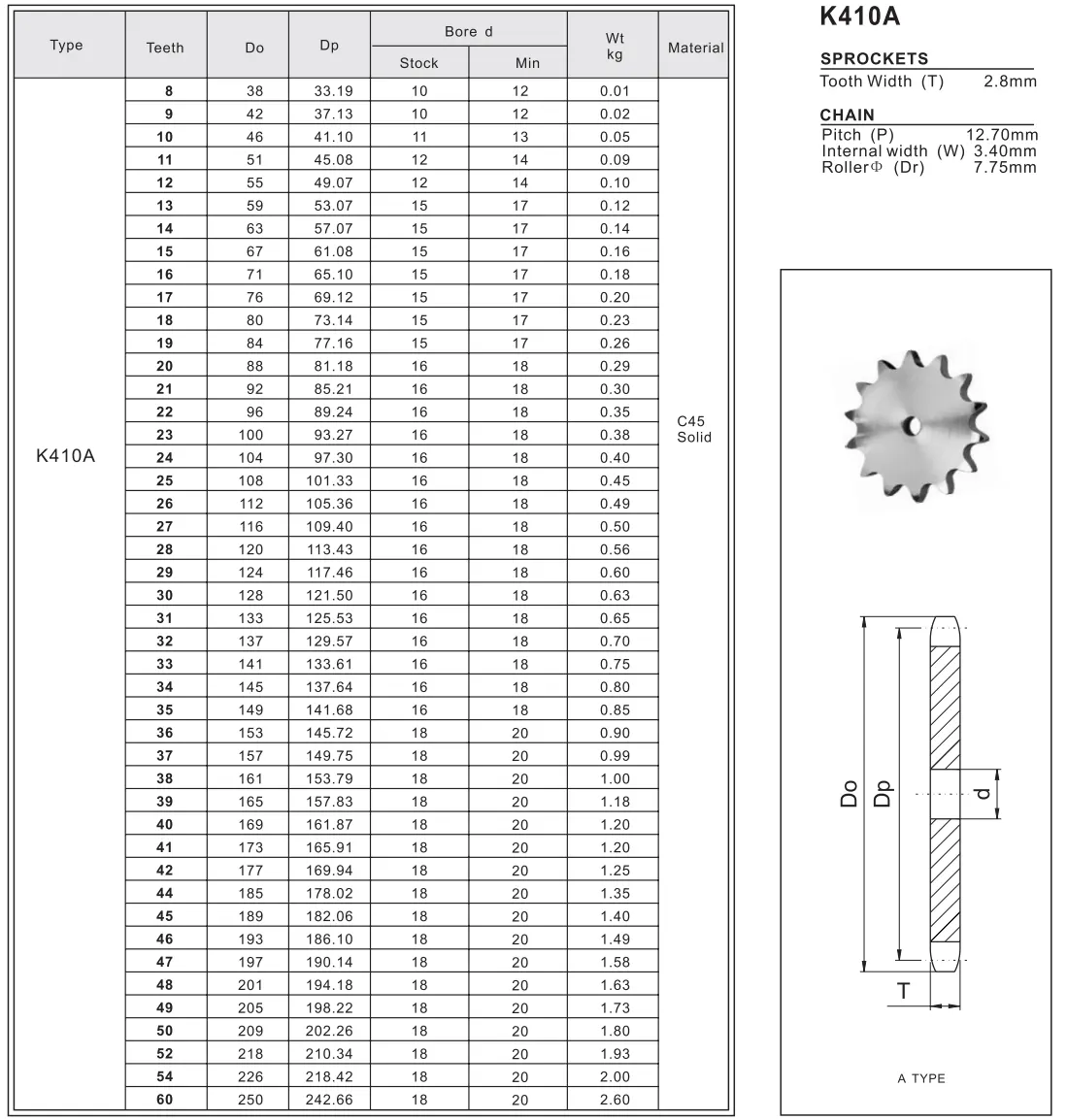

Specifications of Plate Wheel Sprocket K410A

Plate Wheel K410A is a specialized type of plate sprocket integral to various power transmission systems. Constructed from a robust flat plate with precisely engineered teeth, this sprocket is typically mounted on a shaft or hub through a central hole, ensuring a secure fit. Its primary role is to efficiently transfer power between rotating shafts, making it essential for machinery and equipment requiring reliable and consistent power delivery.

Types of Plate Wheel Sprockets

Plate wheel sprockets are available in a range of designs, including single-row, double-row, and multi-row configurations. Each of these types serves distinct applications based on the specific power transmission requirements. For instance, single-row sprockets are often used in applications with lesser load demands, while double-row and multi-row sprockets provide enhanced strength and stability for more demanding operations. The variety ensures that industries can select the most suitable sprocket type for their unique needs, optimizing performance and efficiency.

Product Features of Our Plate Wheel Sprockets

Our plate wheel sprockets are meticulously designed to offer several advantages, focusing on material quality and structural integrity. Key material benefits include notable corrosion resistance, wear resistance, and enhanced strength and toughness. These features ensure longevity and reliability, crucial for high-performance applications. Moreover, our sprockets are engineered to be lightweight without compromising durability, benefiting both performance and ease of installation. The precision manufacturing techniques employed also guarantee a perfect fit, which is critical for maintaining smooth operation within power transmission systems.

Material Advantages:

- Corrosion resistance: Our plate wheel sprockets are crafted from high-quality materials adept at resisting rust and corrosion, ultimately ensuring a longer lifespan. - Wear resistance: Built to withstand the rigors of operation, our sprockets exhibit superior resistance to wear and tear, making them a reliable choice for continuous use. - Strength and toughness: Designed to endure heavy loads and high-stress conditions, our sprockets maintain structural integrity even in challenging environments.

Design Advantages:

- Light weight: The design focuses on a lightweight structure, which minimizes the overall weight of the power transmission system, enhancing efficiency and reducing energy consumption. - Precision manufacturing: Our sprockets undergo rigorous manufacturing processes to meet exact specifications, ensuring a flawless fit and optimal performance in their designated applications. - Surface treatments: Various advanced surface treatments are applied to our sprockets, effectively preventing rust and other forms of corrosion, thereby enhancing their durability and performance.

Our Services

At GBC - Ever-power Australia Agency, we provide a comprehensive suite of services designed to optimize the performance of our customers' power transmission systems. Our offerings include custom design and fabrication, material selection, surface treatment, hardening treatment, and tailored packaging solutions to meet diverse needs.

Custom Design and Fabrication:

We excel in crafting custom plate wheel sprockets tailored to meet the specific requirements of our clients. Our skilled team collaborates closely with customers to develop unique designs from scratch, or adapt existing designs, ensuring an optimized solution for any application. This flexibility allows us to cater to various industries, ensuring they receive exactly what they need for their operations.

Material Selection:

Offering a wide range of material options, including different grades of steel and stainless steel, we assist clients in selecting the most suitable material for their applications. Factors taken into account include environmental conditions, load demands, and intended use, enabling our customers to make informed decisions that enhance performance and longevity.

Surface Treatment:

We provide an array of surface treatments such as electroplating, anodizing, and powder coating. These treatments are crucial for preventing rust and other forms of corrosion, effectively prolonging the operational life of the sprocket and boosting overall effectiveness within the power transmission system.

Hardening Treatment:

Our hardening treatments, such as heat treatment, induction hardening, and nitriding, significantly enhance the strength and durability of our plate wheel sprockets. These processes ensure that the sprockets can bear hefty loads and endure high-stress situations, making them ideal for demanding applications.

Custom Packaging:

We understand the importance of safe transport and storage, which is why we offer custom packaging solutions tailored to the specific needs of our customers. Our team collaborates with clients to create packaging that provides maximum protection, ensuring that products arrive in perfect condition.

Plate Wheel Sprocket Manufacturing Process

The manufacturing of our plate wheel sprockets involves a detailed multi-step process that guarantees quality and performance. This process includes forging, machining, hobbing, teeth heating, quenching, surface treatment, quality inspection, and packaging, each step being pivotal in producing a high-quality sprocket tailored to customer specifications.

Forging:

The manufacturing process begins with forging, where the sprocket is shaped into its desired form. This initial step is crucial as it lays the foundation for the sprocket's performance and durability.

Machining:

Following forging, the sprocket undergoes machining, a process that cuts it to the required specifications. This ensures that the sprocket fits seamlessly into its intended application, which is vital for optimal functionality.

Hobbing:

The hobbing process follows, where precise teeth are cut into the sprocket. This step guarantees that the teeth are evenly spaced and aligned correctly, which is essential for effective power transmission.

Teeth Heating:

After the hobbing, the teeth are heated to a specific temperature, enhancing their hardness and overall durability, which is particularly important for maintaining performance under stress.

Quenching:

Next, the teeth are quenched, or rapidly cooled, to secure the desired hardness and toughness levels. This step is critical in ensuring that the sprocket can effectively handle operational demands.

Surface Treatment/Rust-Proof Treatment:

To prevent rust and corrosion, the sprocket undergoes a thorough surface treatment. This protective measure extends the product's lifespan and optimizes its performance in various environments.

Quality Inspection:

Each sprocket is subjected to rigorous quality inspection, ensuring that it meets the established specifications and quality standards. This step is vital in maintaining the high standards expected by our customers.

Packaging and Shipping:

Finally, the sprocket is carefully packaged and prepared for shipping, ensuring that it arrives safely at its destination, ready for use in various applications.

Plate Wheel Sprocket Maintenance

Maintaining plate wheel sprockets is essential for ensuring their longevity and optimal performance. Key maintenance tasks include regular inspections, cleaning, lubrication, and timely replacement as required.

Daily Inspections:

Daily inspections are crucial for identifying any signs of damage or wear early on. Regular checks can uncover potential issues before they escalate, ensuring the sprocket continues to function effectively.

Cleaning:

Routine cleaning helps to eliminate dirt, debris, and contaminants that can accumulate over time. Keeping the sprocket clean is vital for preventing damage and maintaining peak performance throughout its operational life.

Lubrication:

Regular lubrication is necessary to minimize friction and wear. A well-lubricated sprocket operates more smoothly and has a longer lifespan, ultimately contributing to the overall efficiency of the power transmission system.

Replacement:

The sprocket should be replaced as needed to ensure optimal performance and safety. Regularly assessing its condition and making timely replacements are crucial for maintaining the integrity of the power transmission system.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group and is among the top ten gear suppliers in Australia. Our company specializes in providing a wide range of gear products, including the Plate Wheel Sprocket K410A. With our extensive inventory, we cater to various industries, ensuring that our customers find the perfect fit for their applications.

As a leading supplier, we pride ourselves on the diversity of our gear offerings, including different types, sizes, and materials. Our dedicated team is committed to delivering exceptional service, assisting clients in selecting the right products to meet their specific needs. Furthermore, we understand that not all requirements are standard; hence, we also offer customized solutions. Customers are welcome to bring their designs and samples for non-standard plate wheel sprockets, allowing us to tailor our products to their unique specifications.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket K410A is designed for optimal performance in various mechanical applications. Built with durability in mind, it ensures smooth operation and longevity under demanding conditions. Its precision engineering allows for efficient power transmission, making it an essential component for machinery and vehicles. GBC provides high-quality Plate Wheel Sprockets in Australia, ensuring reliability and excellence in every product.