Plate Wheel Sprocket K60A

The Plate Wheel Sprocket K60A is an essential component designed for durability and efficiency in various mechanical applications. Its robust construction ensures reliable performance, making it suitable for heavy-duty tasks. At GBC, we proudly offer high-quality Plate Wheel Sprockets K60A in Australia, ensuring exceptional standards and customer satisfaction.

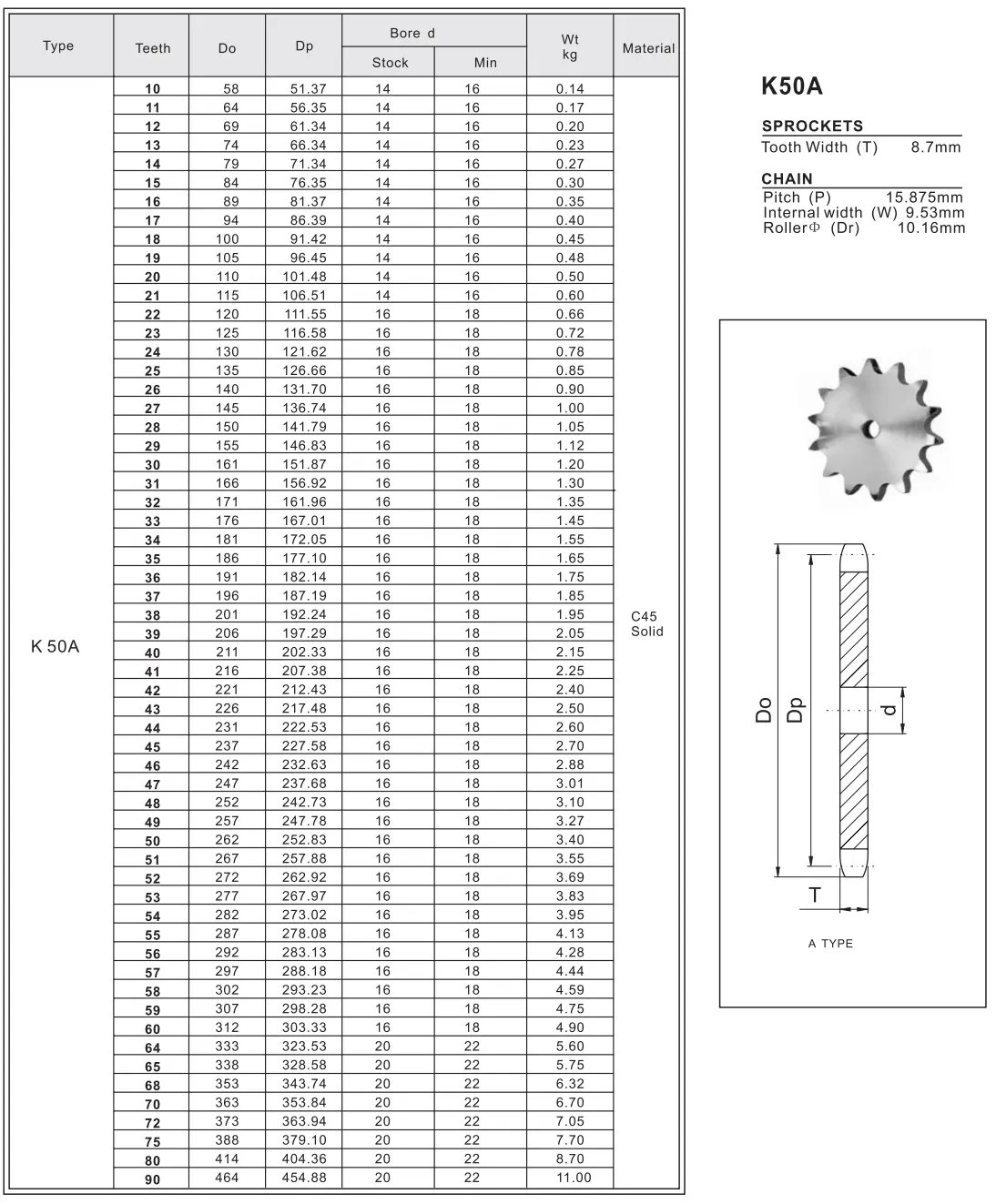

Specifications of Plate Wheel Sprocket K60A

Plate Wheel K60A represents a highly versatile and efficient plate sprocket that is extensively utilized across various transmission systems. Due to its compact design and exceptional durability, it has become a preferred choice among manufacturers and engineers alike. The sprocket features flat, plate-like teeth that effectively engage with a chain, ensuring reliable power transmission. Its robust construction allows it to perform optimally under diverse operational conditions, making it a staple component in many mechanical systems.

Types of Plate Wheel Sprockets

Plate wheel sprockets can be categorized into three distinct types: single-row, double-row, and multi-row sprockets. Single-row sprockets are the most prevalent and are widely employed in straightforward applications. Conversely, double-row and multi-row sprockets cater to complex transmission systems where higher precision and enhanced torque transfer capabilities are paramount. Each type is designed to fulfill specific operational needs, ensuring efficient and effective performance in their respective applications.

Product Features of Our Plate Wheel Sprockets

Material Advantage

Our plate wheel sprockets are constructed from premium quality materials that provide excellent corrosion resistance and wear resistance, along with superior strength and toughness. This combination ensures that our sprockets can endure even the harshest operational environments. The choice of materials is critical, as it directly influences the longevity and reliability of the sprocket, allowing for sustained high performance over time.

Design Features

Precision in design is a hallmark of our plate wheel sprockets. Each sprocket is meticulously manufactured to meet stringent standards, resulting in a lightweight yet durable product capable of delivering exceptional performance. Additionally, we provide a variety of surface treatments to enhance both the durability and corrosion resistance of our sprockets, ensuring they remain functional and reliable throughout their lifespan.

Our Services

We offer a comprehensive range of services designed to maximize the utility and performance of our plate wheel sprockets for our customers. These services include:

Custom Design

We work closely with our customers to develop custom plate wheel sprockets tailored to their specific needs and requirements. This collaborative approach ensures that the final product perfectly aligns with the intended application.

Material Selection

Our clients can choose from an array of high-quality materials, including steel, stainless steel, and plastic. This flexibility enables customers to select the best-suited material for their unique applications, optimizing performance based on their specific conditions.

Surface Treatment

We provide a variety of surface treatments such as black oxide coating, zinc plating, and anodizing. These treatments are essential in enhancing the durability and corrosion resistance of our sprockets, significantly extending their service life and maintaining functionality in challenging environments.

Hardening Treatment

Our heat treatment services, including quenching and tempering, are designed to increase the hardness and overall strength of our sprockets. This process ensures that they can withstand significant stress and wear during operation, maintaining their integrity over time.

Custom Packaging

To cater to the specific needs of our customers, we offer options for custom packaging, including logo printing and specialized labeling. This attention to detail helps ensure that the products arrive in optimal condition while reinforcing brand identity.

Manufacturing Process of Our Plate Wheel Sprockets

Forging

The manufacturing process begins with forging raw materials into the desired shape using a combination of heat and pressure. This step is crucial as it establishes the basic form and structural integrity of the sprocket, preparing it for subsequent processing.

Machining

Following forging, the sprocket undergoes machining to achieve the final dimensions. This process utilizes precision cutting tools to ensure an accurate and high-quality finish, which is essential for the sprocket's performance and compatibility with other components in the system.

Hobbing

The next step involves hobbing, where a specialized cutting tool known as a hob is used to cut the teeth of the sprocket. This process is critical for defining the tooth geometry that allows for efficient engagement with the chain, ensuring smooth operation.

Teeth Heating

To enhance the hardness and durability of the teeth, they are subjected to a heating treatment. This step is vital in ensuring that the sprocket teeth can endure the stresses experienced during operation without deforming or wearing out prematurely.

Treated on Quenching

Following heating, the sprocket is quenched to further bolster its hardness and strength. This rapid cooling process is essential for achieving the desired material properties that contribute to the sprocket's overall performance capabilities.

Surface Treatment/Rust-Proof Treatment

After quenching, a surface treatment is applied to improve corrosion resistance and enhance durability. This protective layer is crucial for extending the lifespan of the sprocket, especially in environments prone to moisture and other corrosive elements.

Quality Inspection

The final sprocket undergoes thorough quality inspection to ensure it meets our stringent standards. This quality control process verifies that each sprocket is free of defects and functions as intended, assuring our customers of its reliability.

Packing and Shipping

Once the inspection is complete, the sprocket is carefully packed to prevent damage during transit. Our meticulous packing procedures ensure that the product arrives at its destination in perfect condition, ready for immediate use.

Maintenance of Plate Wheel Sprockets

Daily Inspection

Regular inspections of the sprocket teeth are essential to identify any signs of wear, damage, or misalignment. It's important to ensure that the sprocket is properly lubricated and free from contaminants, as any neglect in maintenance can lead to operational inefficiencies and premature failure.

Cleaning

Routine cleaning of the sprocket is necessary to remove dirt, dust, and other debris that may accumulate over time. Using a soft brush or cloth along with a mild detergent solution can effectively restore the sprocket's condition, ensuring optimal performance and longevity.

Lubrication

Regular lubrication of the sprocket is crucial for ensuring smooth operation and minimizing wear and tear. It is advisable to use a high-quality lubricant that is specifically designed for the application, as this will enhance the performance of the sprocket and extend its service life.

Replacement

When a sprocket begins to show signs of wear, damage, or misalignment, it is imperative to replace it promptly. Using a high-quality replacement sprocket that adheres to the same specifications as the original is essential for maintaining consistent performance and reliability in the transmission system.

FAQ

Q: What are the advantages of using a plate wheel sprocket?

A: Plate wheel sprockets are compact, efficient, and durable. They are widely used in various transmission systems because of their high performance and reliability.

Q: What materials are plate wheel sprockets made from?

A: Plate wheel sprockets can be made from a variety of materials, including steel, stainless steel, and plastic.

Q: Can I customize my plate wheel sprocket?

A: Yes, we offer custom design services to help you create a sprocket that meets your unique needs and specifications.

Q: How do I maintain my plate wheel sprocket?

A: Regular inspection, cleaning, lubrication, and replacement as needed are all important aspects of plate wheel sprocket maintenance.

Q: What is the lead time for ordering a plate wheel sprocket?

A: Lead times can vary depending on the specific product and quantity ordered. Please contact us for more information.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the high-quality Plate Wheel Sprocket K60A, designed to meet various industrial needs. We understand the importance of versatility in our offerings, which is why we provide a diverse selection of gears to cater to different applications.

As a dedicated supplier, we prioritize customer service, ensuring that all clients receive the support they need throughout their purchasing journey. Additionally, we offer non-standard customization options, allowing us to create bespoke solutions tailored to specific requirements. We encourage customers to bring their designs or samples for custom plate wheel sprockets, ensuring that you get exactly what you need for your projects.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket K60A is an essential component designed for durability and efficiency in various mechanical applications. Its robust construction ensures reliable performance, making it suitable for heavy-duty tasks. At GBC, we proudly offer high-quality Plate Wheel Sprockets K60A in Australia, ensuring exceptional standards and customer satisfaction.