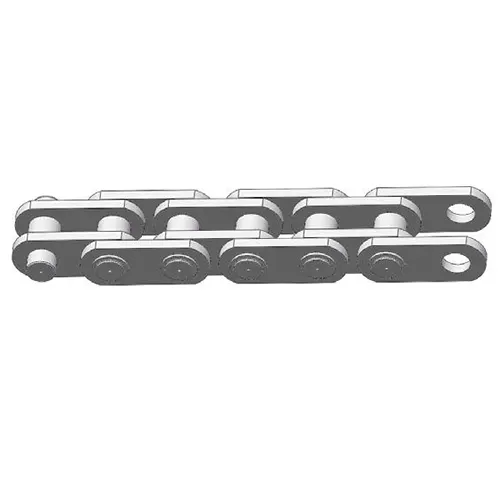

Push Coke Chain

GBC push coke chain is the core drive component in the coke oven system, designed to efficiently and safely push hot coke out of the carbonization chamber under extremely high temperature, heavy load and cyclical operating conditions. This process is an indispensable part of steel production and other heavy industrial processes, which places extremely stringent requirements on the performance of the chain. With its excellent heat resistance, wear resistance and structural strength, the coke pusher chain ensures the continuity and safety of industrial operations.

As Ever-power’s sales agent in Australia, GBC is committed to combining global leading manufacturing technology with a deep understanding of local Australian industrial needs to provide customers with unparalleled power transmission solutions.

Specifications

GBC push coke chains play a vital role in the coke oven system, responsible for efficiently and safely pushing the hot coke out of the carbonization chamber. This operation is fundamental to steel production and other heavy industrial processes. GBC coke pusher chains are designed to handle the most demanding conditions, including extreme temperatures (operating up to 800°C, with coke temperatures approaching 1000°C), huge heavy loads, and continuous cyclic operation. Its design prioritizes excellent heat resistance, outstanding wear resistance, and strong structural integrity, ensuring a long operating life and minimized downtime.

As Ever-power's sales agent in Australia, GBC combines global manufacturing expertise with a deep understanding of Australian industrial needs and local support. The company's commitment to quality, adherence to Australian standards, and professional local support make GBC a preferred partner for critical power transmission solutions.

The table below provides key product specifications for GBC push coke chains.

| Model | Pitch (mm) | Ultimate Tensile Strength (kN) |

|---|---|---|

| AC160 | 160 | 4000 |

| AC190 | 190 | 4000 |

| AC190H | 190 | 7200 |

Unrivalled Performance in Extreme Environments

The Role of Push Coke Chains in Coking Operations: Push coke chains are specialized, heavy-duty drive components designed for the rigorous task of mechanically pushing incandescent coke from the high-temperature carbonization chambers of coke ovens. This is a critical step in the coking process, which converts coal into coke for metallurgical applications, primarily steel production. The chain's robust design ensures the safe and efficient discharge of coke, a process that is fundamental to the continuous operation of steel mills and other heavy industrial facilities. The operation involves the chain enduring immense forces as it propels a large, solid mass of coke, often weighing several tons, out of the oven. This process is highly cyclic and requires exceptional structural strength and resistance to both impact and abrasion. The chain must operate flawlessly under these conditions to prevent costly production delays and safety hazards.

Navigating Extreme Temperatures: While the internal coking temperatures within the oven can reach 900-1100°C, and the coke mass itself is pushed at 950-1000°C, the GBC Push Coke Chain is specifically engineered to perform under these challenging conditions. The chain is not continuously immersed at the highest temperatures, but rather exposed to intense radiant heat from the oven walls and the residual heat of the incandescent coke mass during the brief, yet demanding, pushing cycle. This requires the chain to withstand not only sustained high temperatures but also severe thermal shock and rapid thermal cycling, a complex challenge that GBC's advanced materials are designed to overcome.

Confronting Harsh Conditions: The environment in a coke oven plant during pushing is characterized by extreme heat, immense mechanical stresses from pushing massive loads, constant abrasion from hard coke particles, and potential corrosive elements from residual gases and byproducts. The pusher head itself is often water-cooled to prevent warping and damage from this intense heat, underscoring the severity of the thermal challenge that the push coke chain must endure without such active cooling. It is crucial to distinguish the role of the Push Coke Chain, which handles the discharge of hot, finished coke, from other chains within the coking process, such as drag-type conveyors used for charging coal. The coke pushing operation involves significantly higher temperatures, abrasive forces, and mechanical loads, highlighting the specialized, heavy-duty nature of GBC's product.

The Criticality of Quality: In such a critical and hazardous environment, the failure of a push coke chain can lead to catastrophic operational disruptions, including prolonged and costly unscheduled downtime, significant production losses, and severe safety hazards due to the uncontrolled release or blockage of hot coke. Furthermore, frequent replacements and repairs due to inferior chains incur substantial maintenance and procurement costs. Therefore, investing in high-quality, durable chains is not merely a purchase but a strategic investment in continuous operation, enhanced safety, and long-term cost-efficiency.

Advanced Engineering

Superior Material Science: GBC Push Coke Chains are manufactured from advanced, proprietary heat-resistant alloy steels, specifically engineered to maintain their structural integrity, tensile strength, and mechanical properties under the extreme thermal conditions of coke oven operations (designed for 600-800°C operating temperatures, as per product catalog). These high-performance materials, often referred to as superalloys, are meticulously selected for their exceptional strength, high stability, and remarkable resistance to heat, oxidation, and corrosion, even at temperatures soaring up to 1200°C. Specific examples of such alloys include NCF600 (Inconel600) for high oxidation and corrosion resistance, NCF625 (Inconel625) for superior corrosion resistance across wide temperature ranges and excellent creep strength, and NCF800 (Incoloy800) for outstanding resistance to oxidation and carburization at high temperatures. Additionally, Chromium-Molybdenum Alloy Steel (Chrome Moly) is utilized for its high pressure and temperature capabilities, offering enhanced tensile strength and effective corrosion resistance. Beyond the intrinsic properties of the base materials, our chains undergo advanced anti-oxidation surface treatments. This critical process forms a protective barrier that significantly extends the service life of the chains, particularly in the highly oxidative environments prevalent in coke oven systems where high temperatures accelerate material degradation. The synergistic combination of advanced base materials and specialized anti-oxidation surface treatments ensures comprehensive protection and maximizes the chain's operational lifespan, a critical factor for long-term reliability and reduced total cost of ownership for our Australian clients.

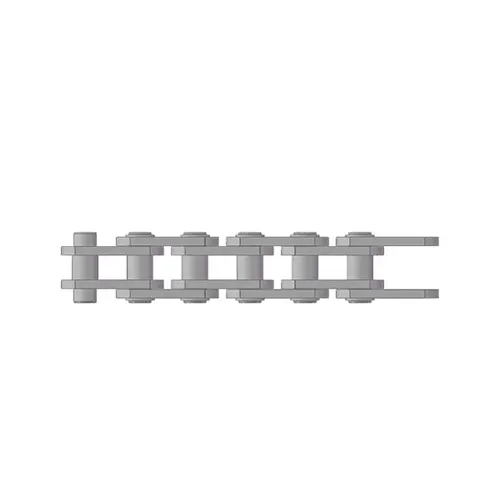

Manufacturing Excellence: Every link in a GBC Push Coke Chain is meticulously designed and engineered to withstand the immense pushing forces, repetitive cyclic stresses, and severe impact loads encountered during the discharge of massive, hot coke masses. This robust design minimizes deformation, prevents premature fatigue, and ensures consistent, reliable performance throughout the chain's operational life. The pins and bushings, which form the critical bearing surfaces within the chain, undergo a series of precision heat treatments, including annealing, quenching, tempering, normalizing, and induction hardening. These processes are meticulously controlled to impart optimal hardness, toughness, and wear resistance. For instance, the use of chrome-hardened pins provides an exceptionally hard and durable surface, significantly reducing friction and wear between the pin and bushing, thereby extending the chain's elongation life and improving its shock-load performance in abrasive, high-temperature environments.

Our manufacturing philosophy integrates cutting-edge technology with meticulous craftsmanship to ensure the highest quality and performance of every GBC Push Coke Chain. This includes:

- Forging: Components are shaped using localized compressive forces, a process that optimizes the metal's grain structure, resulting in exceptionally strong and tough parts capable of enduring extreme loads.

- Specialized Heat Treatments: Precisely controlled thermal processes are applied to achieve specific material properties. These include annealing (to reduce hardness and increase ductility), quenching (rapid cooling to increase hardness), tempering (to enhance toughness after quenching), and normalizing (to relieve internal stresses and refine grain structure). Induction hardening is specifically utilized for surface hardening critical components like pins and bushings, enhancing their wear resistance.

- Shot Peening: A crucial post-treatment process where the surface of components is bombarded with small spherical media. This work-hardens the surface by inducing compressive residual stress, significantly enhancing the component's fatigue strength, wear resistance, and resistance to stress corrosion cracking.

- Advanced Welding Techniques: We employ state-of-the-art welding processes, often combined with post-weld stress relieving and heat treatment, to achieve maximum chain strength and integrity. This is particularly vital for chains operating in highly abrasive and rough environments, where weld integrity is paramount for durability.

These manufacturing steps are not isolated, but form an integrated, sequential, and highly controlled ecosystem. Each stage is meticulously designed to build upon the previous one, cumulatively enhancing the final product's properties (strength, wear resistance, fatigue life, heat resistance). This detailed exposition of how the product is made, demonstrating the depth of engineering knowledge and control, significantly boosts GBC's Expertise and Authority, assuring the customer of the product's superior quality and reliability.

Customer Testimonials

At GBC, we pride ourselves on delivering not just superior products, but also exceptional service that translates into tangible benefits for our clients across Australia. Here’s what some of our valued customers have to say about their experience with GBC Push Coke Chains.

| "Switching to GBC Push Coke Chains was a game-changer for our Port Kembla steelworks. We used to face frequent chain breakages, leading to costly downtime. Since installing GBC chains, our pushing operations have been remarkably smooth, even with the intense heat and heavy loads. The durability is simply unmatched." – Operations Manager, Major Steel Producer, NSW. |

| "Our Whyalla plant requires components that can withstand extreme temperatures and constant abrasion. GBC's chains have proven incredibly robust. Their team in South Australia also provided excellent technical support during installation, ensuring a seamless transition. We've seen a noticeable reduction in maintenance needs." – Procurement Lead, Integrated Steel Mill, SA. |

| "We operate a demanding coking facility in Queensland, and the reliability of our push coke chains is paramount. GBC delivered on their promise of high-performance chains. The anti-oxidation treatment really makes a difference in our high-temperature environment, extending the life far beyond what we experienced with previous suppliers." – Plant Engineer, Coking Operations, QLD. |

| "For our heavy machinery in Western Australia, durability is key. GBC Push Coke Chains were recommended for their high tensile strength and wear resistance. They've exceeded our expectations, performing consistently under heavy cyclic loads. It's clear that the precision heat treatment makes a significant impact on their longevity." – Maintenance Supervisor, Industrial Plant, WA. |

| "We needed a custom solution for a unique coke oven setup, and GBC's engineering team was incredibly responsive. They understood our specific challenges with high temperatures and heavy loads, delivering chains that fit perfectly and perform flawlessly. Their commitment to quality and local service has made them our go-to supplier in Australia." – Project Manager, Industrial Solutions Provider, VIC. |

FAQs

- Q1: What makes GBC Push Coke Chains suitable for extreme temperatures?

A1: GBC Push Coke Chains are manufactured from advanced heat-resistant alloy steels, such as Inconel and Incoloy variants, specifically chosen for their ability to maintain structural integrity and mechanical properties at temperatures up to 800°C operating and resisting thermal shock from coke masses up to 1000°C. Additionally, they feature specialized anti-oxidation surface treatments to prevent degradation in high-temperature, oxidative environments. - Q2: How do GBC chains handle the heavy loads and abrasive conditions in a coke oven?

A2: Our chains feature a high-strength link design engineered to withstand immense pushing forces and severe impact loads. The pins and bushings undergo precision heat treatments, including induction hardening and shot peening, which significantly enhance their hardness, wear resistance, and fatigue strength, ensuring durability against constant abrasion from coke particles. - Q3: What is the typical lifespan of a GBC Push Coke Chain compared to standard chains?

A3: While lifespan can vary based on specific operating conditions and maintenance practices, GBC Push Coke Chains are designed for extended operational life due to their superior material composition, advanced manufacturing processes (like precision heat treatment and anti-oxidation coatings), and robust design. This leads to reduced frequency of replacements and lower overall maintenance costs compared to standard chains not optimized for such extreme environments. - Q4: Can GBC provide customized Push Coke Chains for specific oven designs or operational requirements?

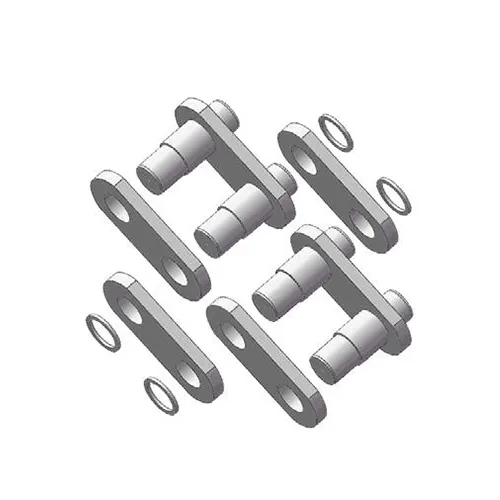

A4: Yes, GBC offers customizable dimensions and attachments to adapt to different coke oven and pusher machine models. Our engineering team works closely with clients to understand their unique needs and provide tailored solutions that optimize performance and fit existing systems. - Q5: What kind of after-sales support does GBC offer in Australia?

A5: As the Australian sales agent for Ever-power, GBC provides comprehensive local support, including technical consultation, installation guidance, and ongoing maintenance advice. Our team of experts is dedicated to ensuring the long-term performance and reliability of your GBC Push Coke Chains.

Related Products and Solutions

GBC offers a comprehensive range of power transmission products beyond Push Coke Chains that are essential for heavy industrial applications in Australia:

Industrial Transmission Roller Chains: Designed for various power transmission needs, offering durability and efficiency.

Conveyor Chains: A wide array of conveyor chains for different material handling applications, including those in mining, cement, and sugar industries.

Sprockets: Precision-manufactured sprockets optimized to work seamlessly with our chains, ensuring efficient power transfer and extended system life.

Couplings and Pulleys: Essential components for various power transmission systems, ensuring smooth operation and reliable performance.

These complementary products are all sourced with the same commitment to quality and performance that defines GBC Push Coke Chains, providing a one-stop solution for Australia's industrial power transmission needs.

GBC push coke chain is the core drive component in the coke oven system, designed to efficiently and safely push hot coke out of the carbonization chamber under extremely high temperature, heavy load and cyclical operating conditions. This process is an indispensable part of steel production and other heavy industrial processes, which places extremely stringent requirements on the performance of the chain. With its excellent heat resistance, wear resistance and structural strength, the coke pusher chain ensures the continuity and safety of industrial operations.

As Ever-power’s sales agent in Australia, GBC is committed to combining global leading manufacturing technology with a deep understanding of local Australian industrial needs to provide customers with unparalleled power transmission solutions.