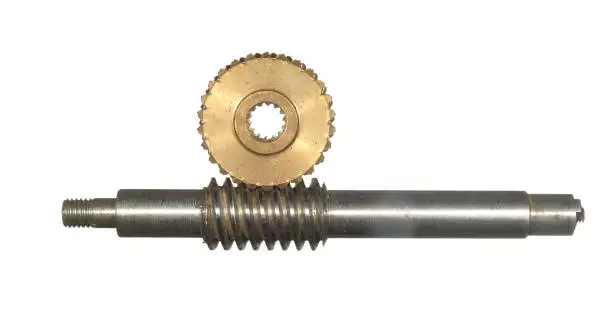

Reverse Worm Gear

The Reverse Worm Gear is a specialized mechanical device designed to convert rotational motion into linear motion. This innovative gear system comprises a Worm Gear paired with a Worm Wheel, ensuring smooth operation and high torque output. Typically made from durable materials such as hardened steel or aluminum, the Reverse Worm Gear is ideal for applications requiring precise movement and efficient power transmission. The combination of the Worm Shaft and Worm Screw allows for a compact design, making it suitable for various machinery and automation systems.

Specifications of Reverse Worm Gear

| Specification | Value |

|---|---|

| Gear Ratio | 10:1 |

| Input Shaft Diameter | 30 mm |

| Output Shaft Diameter | 20 mm |

| Material | Aluminum Alloy |

| Max Torque | 50 Nm |

| Efficiency | 85% |

Features and Advantages of Reverse Worm Gear

The Reverse Worm Gear is a highly efficient mechanical system that offers several key benefits:

- High Torque Output: The Reverse Worm Gear design allows for increased torque, making it ideal for heavy-duty applications.

- Compact Size: With a compact configuration, the Worm Gear is suitable for installations with space constraints.

- Durability: Constructed from high-quality materials, the Worm Wheel and Worm Shaft ensure long-lasting performance.

- Low Noise Operation: The smooth interaction between the Worm Screw and Worm Gear minimizes noise during operation.

- Versatility: Reverse Worm Gears can be used in various applications, from automotive to industrial machinery.

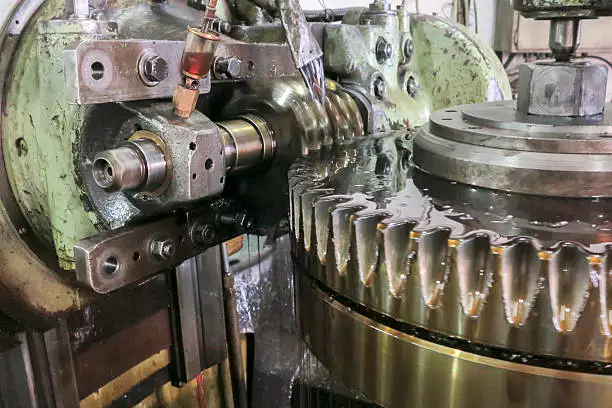

Applications of Reverse Worm Gear in Mechanical Systems

The Reverse Worm Gear is essential in various mechanical applications, providing efficient speed reduction and torque amplification. This gear mechanism comprises a Worm Gear, Worm Wheel, Worm Shaft, and Worm Screw, making it ideal for precise control in machinery. Its design allows for smooth operation, making it suitable for conveyors, elevators, and robotics, where directional movement is crucial. The Reverse Worm Gear helps ensure stability and reliability, contributing to the overall efficiency of the system.

Maintenance Tips for Reverse Worm Gear

- Regular Lubrication: To ensure optimal performance of your Reverse Worm Gear, it is essential to maintain proper lubrication. The Worm Gear and Worm Wheel should be lubricated regularly to minimize friction between moving parts. Use high-quality lubricant specifically designed for worm drives to enhance the lifespan of the Worm Shaft and Worm Screw. Check for any signs of lubricant leakage or contamination, and replace the lubricant as necessary. This practice not only reduces wear and tear but also prevents overheating, thus prolonging the life of the components.

- Visual Inspections: Routine visual inspections of the Reverse Worm Gear setup can help identify potential issues before they escalate. Examine the Worm Gear, Worm Wheel, and Worm Shaft for any signs of wear, such as pitting, scoring, or unusual wear patterns. Look for signs of misalignment or loose fittings that could lead to inefficiencies. Addressing these concerns early can prevent significant operational failures and extend the life of the Worm Screw and associated components. Always ensure that safety precautions are followed during inspections.

- Load Analysis: Understanding the load your Reverse Worm Gear is subjected to is crucial for its maintenance. Overloading can lead to excessive wear on the Worm Gear and Worm Wheel, causing premature failure. Ensure that the load specifications are within the recommended limits to maintain efficiency and durability. If you notice any unusual noises or vibrations during operation, it may indicate that the load is too high or that there's an issue with the Worm Shaft. Regularly reviewing and adjusting the load can significantly extend the lifespan of your equipment.

- Temperature Monitoring: High temperatures can adversely affect the performance of the Reverse Worm Gear. Implementing a temperature monitoring system can help keep track of the operating conditions. Excessive heat can lead to thermal expansion and increased wear on the Worm Screw, Worm Shaft, and other components. If the temperature exceeds the recommended limits, consider adjusting the lubrication or load to prevent damage. Regular temperature checks can prevent operational failures and extend the overall lifespan of the worm drive system.

Worm Gear Manufacturer - GBC

Worm gears are essential components in various mechanical systems, providing the necessary torque and speed reduction for efficient operation. Choosing a suitable supplier is crucial to ensure high-quality products that meet specific application requirements.

GBC is the Australian sales agent for Ever-power Group and stands as one of the leading suppliers and manufacturers of worm gears in Australia. Our expertise in this field allows us to offer reliable worm gear solutions tailored to diverse industrial needs.

Our product range includes reverse worm gears, designed for applications requiring precise motion control and high efficiency. These gears are crafted with precision engineering, ensuring durability and performance in various operational settings.

With a strong commitment to quality and customer satisfaction, our company prides itself on delivering exceptional service and robust solutions to meet the unique demands of our clients.

Additional information

| Edited | Sylvia |

|---|

The Reverse Worm Gear is a specialized mechanical device designed to convert rotational motion into linear motion. This innovative gear system comprises a Worm Gear paired with a Worm Wheel, ensuring smooth operation and high torque output. Typically made from durable materials such as hardened steel or aluminum, the Reverse Worm Gear is ideal for applications requiring precise movement and efficient power transmission. The combination of the Worm Shaft and Worm Screw allows for a compact design, making it suitable for various machinery and automation systems.