Shuttle Car Scraper Chain DA711 Series

The GBC shuttle car scraper chain offers unmatched durability and performance, making it a top choice for underground mining operations. As a leading shuttle car chain manufacturer, GBC provides high-quality chains designed for heavy-duty applications. These chains are built to withstand the toughest conditions, minimizing downtime and maintenance costs. Their robust construction ensures efficient material transport, reducing operational disruptions. Whether for coal, metal, or other mining operations, the GBC shuttle car scraper chain guarantees reliability, cost-effectiveness, and extended service life.

Introduction

The shuttle car scraper chain is an important transmission component in the mine transportation system and is widely used in the underground transportation systems of coal mines, metal mines and other mines. Its main function is to transport materials such as ores and coal from the mining area of the mine to the surface or other processing areas through scraper chains. Our company provides the DA711 series shuttle car scraper chain.

Shuttle Car Chain System Parts and Specifications

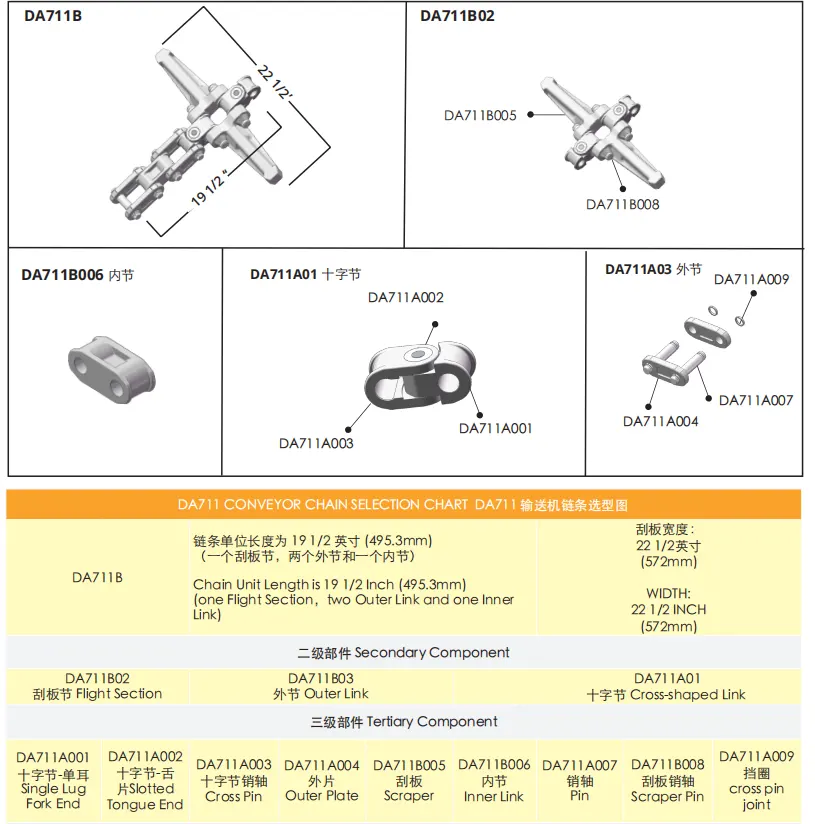

We offer complete shuttle car conveyor chain systems, including various types of accessories such as cross-shaped link (DA711A01), flight section (DA711B02), and internal link (DA711B06). Each component can work seamlessly together to ensure the efficient operation of the chain system.

Our chains adopt a width of 22 1/2 inches (572mm) and can adapt to the needs of different mining operations, ensuring the efficiency and safety of the transportation process.

Functions and Features

- Material conveying

The scraper chain for shuttle car, by connecting the scrapers of the mine car, forms a closed conveying chain system, which can effectively transport ores or coal from underground to the surface or other processing facilities. The scraper pushes the material to the end of the chain, completing the material conveying process. - Enhance load-bearing capacity

The mining shuttle car chain is composed of sturdy metal links, which can bear a considerable weight and adapt to the heavy loads encountered by mine cars during transportation, thus ensuring the stability and safety of the transportation system. - Improve transportation efficiency

The mining scraper chain has the ability to rotate at high speed, which can complete the transportation of large quantities of materials in a short time, greatly improving the operation efficiency of the mine. - Reduce material loss

Due to the precise control of the shuttle car scraper chain during the material transportation process, it can effectively reduce the flipping and spillage of materials, lowering the loss of ores or coal.

Applications

Shuttle car scraper chain plays an important role in multiple industrial fields. In the underground mine operation environment, due to the narrow space of the tunnel, traditional transportation methods are difficult to be implemented. However, the industrial scraper chain of the shuttle mine car, with its unique design, can achieve continuous and stable transportation of ores in the narrow space, ensuring the efficient progress of underground mining operations. In open-pit mines, it is often closely coordinated with crushers or loaders to complete the short-distance transportation of ores from the mining point to the processing point, effectively enhancing the overall efficiency of open-pit mining. In addition, in the field of tunnel engineering, the mining equipment scraper chain is also indispensable. It is integrated into the rear supporting system of the shield machine or TBM, responsible for timely discharging the debris generated during the excavation process, providing strong support for the smooth progress of the tunnel.

Common Faults and Solutions

| Faults | Reasons | Solutions |

| The chain broke | Overload (such as a single loading exceeding the designed load by 120%), chain fatigue (used for more than 5 years or with a conveying volume exceeding 300,000 tons). | Select high-strength chains (safety factor ≥8) and install overload protection sensors (such as tension detectors). |

| Scraper deformation | Large pieces of material get stuck on the scraper (such as rocks with a particle size greater than 300mm), causing uneven force on the chain. | Install a grid screen at the loading port to limit the particle size of the material and adopt an anti-jamming scraper design (such as an elastic buffer structure). |

Click and check more problems and solutions here.

Reviews

| Rajiv Patel, Technical Specialist | Elias Morgan, Senior Engineer | Samuel Pritchard, Mining Operations Manager |

| As a supplier of mining equipment, we always look for products that stand the test of time. The shuttle car scraper chain has proven itself in our tests, with excellent performance under heavy loads. The chain is well-made, easy to install, and operates smoothly in our shuttle car systems. We’ve seen a reduction in operational costs due to its efficiency. | The shuttle car scraper chain we ordered has exceeded expectations. It’s incredibly robust, capable of withstanding the constant stress and wear from moving large volumes of coal. Installation was simple, and the chain runs smoothly without issue. It integrates well with our existing system, improving transport efficiency without requiring frequent replacements or maintenance. | We've been using the shuttle car scraper chain in our underground coal mine for several months now. The durability is impressive, with minimal wear despite continuous use in harsh conditions. The chain's smooth operation has reduced our downtime significantly, and we appreciate the reliable performance. It fits perfectly with our existing equipment, and installation was straightforward. |

How to Choose Shuttle Car Scraper Chain?

Selecting the right shuttle car scraper chain involves assessing your mining needs—consider durability, load capacity, and compatibility with your equipment. Opt for a trusted shuttle car chain manufacturer with proven expertise, and check for wear-resistant materials suited to underground conditions. Always request a mining equipment parts quote to compare quality and cost effectively.

For top-notch options, turn to Ever-power’s Australian sales agent, GBC. We serve New South Wales, Victoria, Queensland, and cover cities like Sydney, Melbourne, Brisbane, Adelaide, and Perth. Beyond Australia, we offer global sales support. As a leading shuttle car scraper chain supplier, we make it easy to buy shuttle car scraper chains tailored to your operations. Contact us today for a quote and elevate your mining efficiency!

The GBC shuttle car scraper chain offers unmatched durability and performance, making it a top choice for underground mining operations. As a leading shuttle car chain manufacturer, GBC provides high-quality chains designed for heavy-duty applications. These chains are built to withstand the toughest conditions, minimizing downtime and maintenance costs. Their robust construction ensures efficient material transport, reducing operational disruptions. Whether for coal, metal, or other mining operations, the GBC shuttle car scraper chain guarantees reliability, cost-effectiveness, and extended service life.