Steel Helical Tetragon Milled Hardened Gear Rack

The CHTMH series Steel Helical Tetragon Milled Hardened Gear Rack by GBC stands out for its superior strength and precision engineering. Designed for durability, this gear rack offers enhanced load capacity and reduced noise during operation, making it ideal for various industrial applications. As a trusted manufacturer, GBC ensures that each gear rack undergoes stringent quality checks, providing reliable performance that meets the demands of modern machinery. Choose GBC for your next procurement, and experience the difference in efficiency and longevity.

Introduction

The Steel Helical Tetragon Milled Hardened Gear Rack is made from high-quality hardened steel, ensuring durability and strength. Its unique helical tooth design allows for smoother operation and reduced noise, making it ideal for precision machinery and automation applications. This gear rack is versatile, suitable for various industries, including robotics and manufacturing. Our product stands out due to its meticulous milling process, which guarantees tight tolerances and superior performance, ensuring a longer lifespan and reliability in demanding environments. Choose our gear rack for unparalleled quality and efficiency in your mechanical systems.

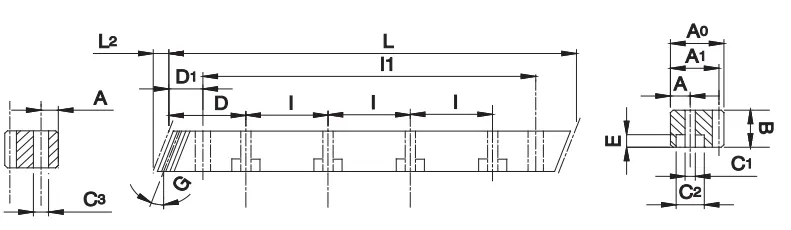

Product Parameters

Manufacturing Description:

Precision Grade: DIN 10e27

Material: S45C

Type: Helical Rack

Treatment of Teeth: Milled

Hardness: High Frequency.HRC48~52 Degree

Sides Ground :not included

Right Hand Angle:19°31'42”

Pressure Angle:20 Degree

Total Pitch Error:0.2mm/1000mm

| 型号 Code |

模数 Module |

L | L2 | 齿数 Tooth No. |

B | A0 | A1 | D | I | 孔数 Hole No. |

A | C1 | C2 | E | D1 | 11 | C3 | ||

| CHTMH | 010 | 05 | 1 | 500.00 | 5.35 | 150 | 15 | 15 | 14 | _ | _ | _ | _ | _ | _ | _ | _ | _ | _ |

| CHTMH | 015 | 05 | 1.5 | 500.00 | 6.7 | 100 | 19 | 19 | 17.5 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| CHTMH | 015 | 10 | 1.5 | 1000.00 | 6.7 | 200 | 19 | 19 | 17.5 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| CHTMH | 020 | 05 | 2 | 500.00 | 8.5 | 75 | 24 | 24 | 22 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 |

| CHTMH | 020 | 10 | 2 | 1000.00 | 8.5 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 |

| CHTMH | 030 | 05 | 3 | 500.00 | 10.3 | 50 | 29 | 29 | 26 | 62.5 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 |

| CHTMH | 030 | 10 | 3 | 1000.00 | 10.3 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 |

| CHTMH | 040 | 05 | 4 | 506.67 | 13.8 | 38 | 39 | 39 | 35 | 62.5 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 |

| CHTMH | 040 | 10 | 4 | 1000.00 | 13.8 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.0 | 7.7 |

| CHTMH | 050 | 05 | 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.5 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 |

| CHTMH | 050 | 10 | 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 |

| CHTMH | 060 | 05 | 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.5 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 |

| CHTMH | 060 | 10 | 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 |

| CHTMH | 080 | 05 | 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.0 | 120 | 4 | 25 | 22 | 33 | 21 | 120 | 240.0 | 19.7 |

| CHTMH | 080 | 10 | 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.0 | 120 | 8 | 25 | 22 | 33 | 21 | 120 | 720.0 | 19.7 |

| CHTMH | 100 | 10 | 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125 | 750.0 | 19.7 |

| CHTMH | 120 | 10 | 12 | 1000.00 | 42.56 | 25 | 120 | 120 | 108 | 40 | 125 | 8 | 40 | 39 | 58 | 38 | 102.5 | 750.0 | 19.7 |

Applications

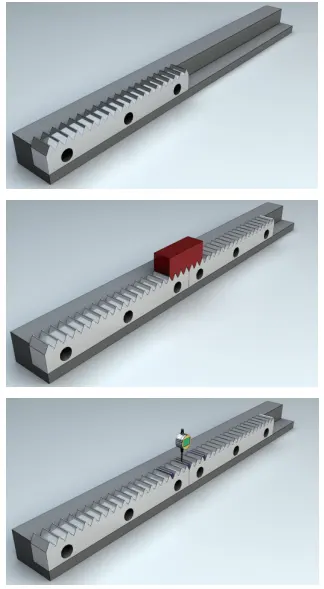

The Steel Helical Tetragon Milled Hardened Gear Rack is engineered for precision and durability, making it ideal for various industrial applications. Its helical tooth design allows for smoother operation and reduced noise, which is essential in high-speed machinery. Common applications include automated systems, robotics, and CNC machinery, where it plays a crucial role in translating rotational motion into linear movement. Additionally, its hardened surface ensures longevity and resistance to wear, making it suitable for heavy-duty tasks in harsh environments.

Assembly Instructions

The Steel Helical Tetragon Milled Hardened Gear Rack is designed for seamless assembly, allowing multiple racks to be connected for any desired length. During assembly, it is crucial to adjust the gap between two racks to ensure compatibility with the pitch of the gears. The installation of the gear rack should utilize positioning pins for accuracy.

- Position and secure the first gear rack in place.

- Use a reverse tooth gauge to accurately position the next gear rack.

- Individually check each connection point and use a feeler gauge to measure the parallelism of the racks.

Make sure to take your time with each step to ensure proper alignment and function of the gear racks. Proper assembly will result in improved performance and longevity of the system.

Why Choose GBC Gear Racks

GBC is the Australian sales agent for Ever-power, a company with nearly 20 years of experience in the production of gear racks. Over the years, Ever-power has established a scientifically managed system for product production and quality inspection, ensuring high quality and cost-effectiveness of our products. Our gear racks achieve precision levels of up to Grade 5 according to the German DIN3962 standard, with a maximum single piece length of 3200mm. We can manufacture a wide variety of straight and helical gear racks from module 1 to 22, tailored to meet customer specifications.

Our Steel Helical Tetragon Milled Hardened Gear Rack is engineered for durability and precision, making it an ideal choice for high-performance applications.

We pride ourselves on offering exceptional customer service, ensuring that our clients receive the support and assistance they need throughout their purchasing journey.

The CHTMH series Steel Helical Tetragon Milled Hardened Gear Rack by GBC stands out for its superior strength and precision engineering. Designed for durability, this gear rack offers enhanced load capacity and reduced noise during operation, making it ideal for various industrial applications. As a trusted manufacturer, GBC ensures that each gear rack undergoes stringent quality checks, providing reliable performance that meets the demands of modern machinery. Choose GBC for your next procurement, and experience the difference in efficiency and longevity.