Transmission Chain

H series transmission chains are designed to withstand heavy loads, impact loads and abrasive environments, and are widely used in mining, agriculture, construction and heavy conveyor systems. Its core advantage lies in the use of high-quality alloy steel and the use of precise automated assembly processes to ensure that all H series chain products meet strict tolerance standards, thereby maximizing service life.

H Series Chain Code and Pitch

H series transmission chains are available in a variety of specifications to meet the needs of different applications. The following are H series chain codes and their corresponding pitch data:

| H Series Chain Code | Pitch (mm) |

|---|---|

| H60 | 19.05 |

| H80 | 25.40 |

| H100 | 31.75 |

| H120 | 38.10 |

| H140 | 44.45 |

| H160 | 50.80 |

| H180 | 57.15 |

| H200 | 63.50 |

| H240 | 76.20 |

| H10B | 15.88 |

| H12B | 19.05 |

| H16B | 25.40 |

| H20B | 31.75 |

| H24B | 38.10 |

| H28B | 44.45 |

| H32B | 50.80 |

| H40B | 63.50 |

| H48B | 76.20 |

Key Features and Benefits

The superior performance of the H Series Drive Chain is due to its unique design and manufacturing process, which enables it to excel in harsh industrial applications:

- Corrosion Resistance: The H Series Drive Chain is manufactured with an upgraded alloy steel that can effectively resist corrosion in harsh environments. This material selection ensures long-term stability in moisture, chemical exposure or highly abrasive conditions, significantly extending the service life of the product.

- Fatigue Resistance: The chain is carefully designed to withstand repeated stresses, effectively avoiding fatigue failure and ensuring stable operation under cyclic loads. This is critical for applications that require frequent starts and stops or withstand periodic shocks, such as mining machinery and heavy conveying equipment.

- Heat Treatment: All chain components are professionally heat treated to significantly increase hardness and wear resistance. This critical process step ensures that the chain can resist wear and maintain its structural integrity and transmission efficiency during continuous operation.

- Lubrication Options: The H Series Drive Chain is compatible with advanced self-lubricating functions or external lubrication systems to meet different maintenance needs. Proper lubrication can further reduce friction and wear, thereby extending the chain's operating life and reducing maintenance costs.

- Heavy-duty application capability: H series chains are designed to withstand extremely high loads and shocks, and are particularly suitable for heavy industrial applications such as mining, which are often accompanied by huge shock loads and abrasive conditions.

Materials and Manufacturing Process

GBC H Series Drive Chain is made of high-quality alloy steel and undergoes a series of advanced manufacturing processes to ensure its excellent performance and durability.

Raw Material Preparation: The production process begins with the selection of high-quality steel wire rods, which are selected for their strength and durability. The steel wire rods are unwound and enter the wire drawing box through guide rings, where they are lubricated and reduced in diameter in the wire drawing die to increase their tensile strength in preparation for the forming stage.

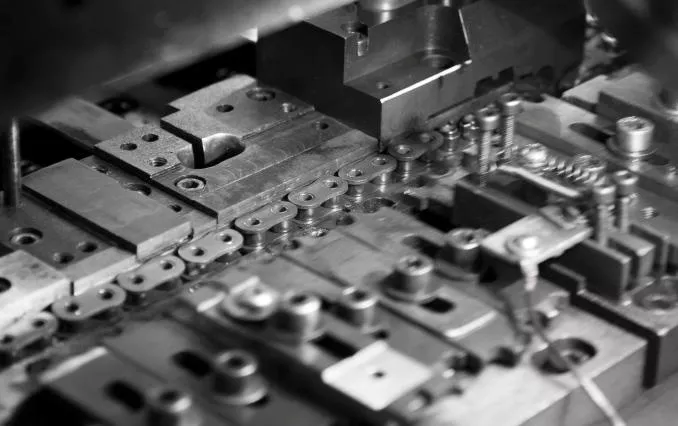

Forming the Links: The lubricated steel wire is fed into the forming machine, bent into a "C" shape, and then closed to form a complete link. This process is repeated to create multiple links that are connected to each other. Steel knives notch the wire at predetermined intervals, a mechanical device then cuts the wire at these notches, and roller arms shape the cut steel into precise links, ensuring uniformity and secure connections between each link.

Welding and Heat Treatment: After forming, each link is joined together by electric welding, without the need for filler material, ensuring the strength and integrity of the chain. After welding, the chain is heat treated, first heated to approximately 1724°F (940°C) and rapidly cooled in water (quenching) to harden the steel. This is followed by tempering, heating to a lower temperature and cooling slowly to increase the toughness and elasticity of the steel, making it suitable for heavy-duty applications.

Final Processing: After heat treatment, the chain is calibrated to ensure uniformity of link size and strength. Samples are tested regularly to verify weld integrity and overall mechanical properties to ensure strict quality standards are met. Depending on the intended use, the chain may also undergo additional surface treatments such as sandblasting to remove surface imperfections, galvanizing for enhanced corrosion resistance, or application of specialized coatings to enhance the chain’s durability and performance in harsh environments.

These precision manufacturing processes, combined with stringent quality control, ensure that the H Series drive chain provides reliable, long-life performance in a variety of heavy-duty applications.

Application Scenarios in Australia

H-Series Drive Chain has broad application prospects in the Australian market, especially in core industries such as mining, agriculture, construction and heavy conveying.

| Mining Industry: | Construction Equipment: | Agricultural Equipment: |

| Australia is a global leader in mineral exports, and the mining industry continues to have strong demand for heavy machinery parts. Designed to withstand high loads, impacts and abrasive environments, H-Series Drive Chain is ideal for excavators, dump trucks, loaders and heavy conveyor systems in mines. For example, in Queensland and Western Australia, mining equipment operates in extreme conditions and requires frequent replacement of components such as engine parts, brake systems and hydraulic cylinders. With rising commodity prices and increased mining activities, the demand for durable, high-performance components such as H-Series Drive Chain will continue to grow. | Australia's infrastructure construction continues to expand, and government-led initiatives such as the Inland Rail Project, major road upgrades and public transportation improvements have created a sustained demand for earthmoving and construction equipment. H-Series drive chains play a key role in lifting machinery, concrete mixing equipment, and heavy material handling equipment, ensuring that these equipment can operate efficiently and reliably on demanding construction sites. Urban development and population growth in cities such as Sydney and Melbourne have also further supported the growth of construction activities, increasing the demand for durable drive chains. | Agriculture is a key part of the Australian economy and the industry is gradually transforming towards mechanization. Farms are increasingly using advanced equipment such as harvesters, balers and tractors to improve productivity and reduce labor dependence. H-Series drive chains provide reliable power transmission in these agricultural machinery, especially in remote areas where equipment downtime can result in significant yield losses. Changing weather patterns and the push for sustainable practices are also prompting farmers to invest in newer, more efficient machines, which in turn has increased the demand for compatible components and upgrades. |

| Lumber Industry: | Heavy Duty Conveying Systems: | |

| In wood processing and forestry machinery, drive chains need to withstand heavy loads, impacts and harsh environments (such as wood chips, moisture). The wear and fatigue resistance of H-Series drive chains makes them ideal for wood conveying systems, sawmill equipment and forestry machinery. | In addition to the mining industry, H series transmission chains are also widely used in other industries that require heavy material handling, such as cement, steel, ports, etc. It can withstand frequent impact loads and abrasive environments, ensuring efficient and stable operation of the conveyor belt system. |

Customer Testimonials

| In our Western Australian iron ore mine, we faced constant chain failures on our heavy conveyors due to extreme dust and shock loads. Since switching to GBC H Series chains, our downtime has significantly reduced, and we've seen a remarkable improvement in operational efficiency. The durability is truly impressive. |

| As an agricultural machinery operator in rural Victoria, reliable chains are non-negotiable, especially during harvest season. We previously struggled with chains wearing out too quickly. GBC's H Series chains have proven to be incredibly robust, handling the demanding conditions of our balers and harvesters with ease. Their heat-treated components make a real difference. |

| For our construction projects in Sydney, where equipment operates under immense pressure, finding a transmission chain that could consistently withstand heavy lifting was a challenge. EVER-POWER H Series chains have exceeded our expectations, providing the strength and fatigue resistance we need. The local support from their Australian team has also been exceptional. |

| Our lumber mill in Queensland requires chains that can endure continuous, abrasive use. We used to experience frequent breakages, leading to costly production halts. The upgrade to GBC H Series chains has been a game-changer. The corrosion resistance and extended wear life mean less maintenance and more consistent throughput. |

| The self-lubricating options on the H Series transmission chains have been a huge benefit for our remote pumping stations in the Northern Territory. Reduced maintenance visits mean lower operational costs and greater reliability in challenging environments. We appreciate the innovation and the tangible savings. |

Related Products

To ensure the longevity and efficiency of your H-Series transmission chains, selecting the right complementary components is crucial. We offer a range of products designed to work seamlessly with our chains.

Sprockets are essential partners to your transmission chains, ensuring smooth and efficient power transfer. We provide high-quality sprockets engineered to match the precise specifications of our H-Series chains, including options with hardened teeth for demanding applications.

Q&A

- Q: What makes H Series chains "heavy duty"?

- A: H Series chains feature thicker link plates and enhanced heat treatment, providing superior tensile strength, fatigue resistance, and shock load capacity compared to standard roller chains.

- Q: Are H Series chains compatible with standard sprockets?

- A: Yes, H Series chains are generally designed to be compatible with standard ANSI sprockets, though specific application requirements may necessitate hardened teeth sprockets.

- Q: How often should H Series chains be lubricated in Australian mining conditions?

- A: Lubrication frequency depends on the specific operating environment and load. For harsh mining conditions, more frequent inspection and lubrication, or the use of advanced self-lubricating options, is recommended to maximize chain life.

- Q: Can you provide custom H Series chain lengths?

- A: Yes, we can provide H Series chains in custom lengths to meet specific project requirements. Please contact our sales team for tailored solutions.

- Q: What is the typical lead time for H Series chain orders in Australia?

- A: Lead times vary based on order volume and specific customization. Our Australian distribution network aims for efficient delivery. Please contact us for an accurate estimate for your order.

H series transmission chains are designed to withstand heavy loads, impact loads and abrasive environments, and are widely used in mining, agriculture, construction and heavy conveyor systems. Its core advantage lies in the use of high-quality alloy steel and the use of precise automated assembly processes to ensure that all H series chain products meet strict tolerance standards, thereby maximizing service life.