Winch Drive for Automated Production Line Hoists

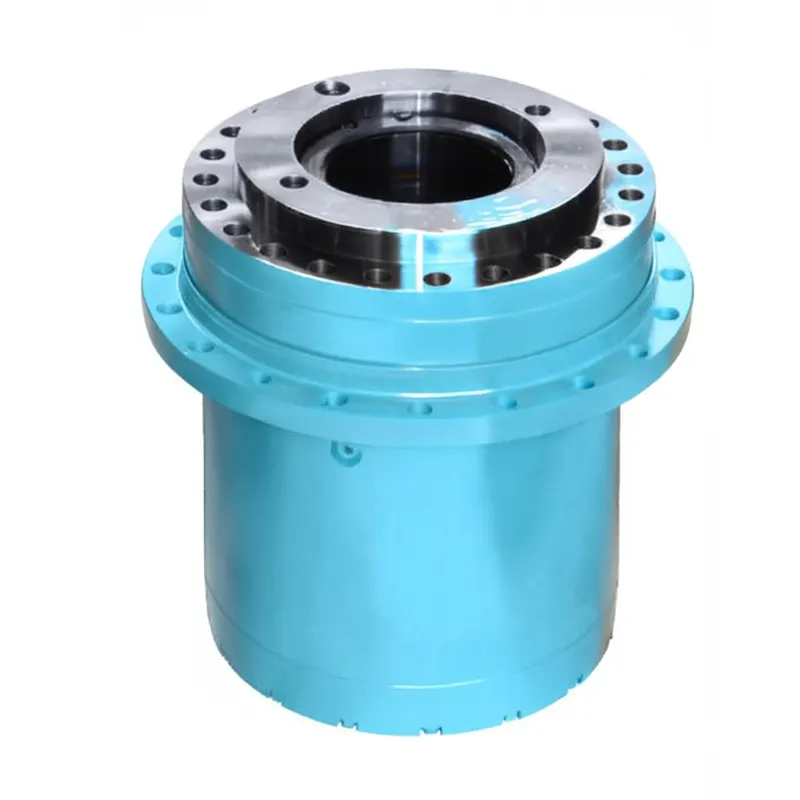

The Winch Drive Planetary Gearbox is a crucial component designed for automated production line hoists. This gearbox efficiently transmits power and enhances torque, enabling smooth and reliable lifting operations. Its planetary design ensures compactness and durability, making it ideal for various applications in winching systems, promoting productivity and safety in industrial settings.

Winch Drive Planetary Gearbox for Automated Production Line Hoists

The Winch Drive Planetary Gearbox is designed for high efficiency and reliability in automated production line hoists. Its compact design and superior torque output enhance performance, ensuring smooth operation and reduced maintenance costs.