Pulleys (Sheaves)

V Belt Pulleys

Timing Belt Pulleys

Our company, as a professional pulley manufacturer in Australia, mainly deals in industrial pulleys for sale. The belt drive pulley types include V pulleys and timing pulleys. V-belt pulleys achieve efficient power transmission through friction drive, while synchronous pulleys ensure precise operation without slip-through toothed meshing. They are suitable for heavy-duty and precision transmission scenarios. We assist customers in optimizing equipment performance with high-quality products to meet diverse industrial demands.

V-Belt Pulleys

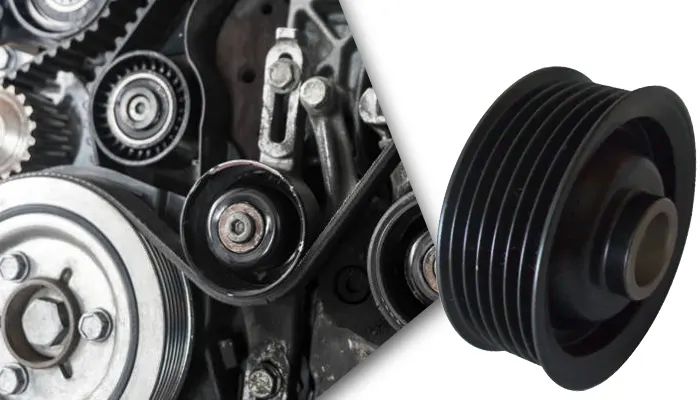

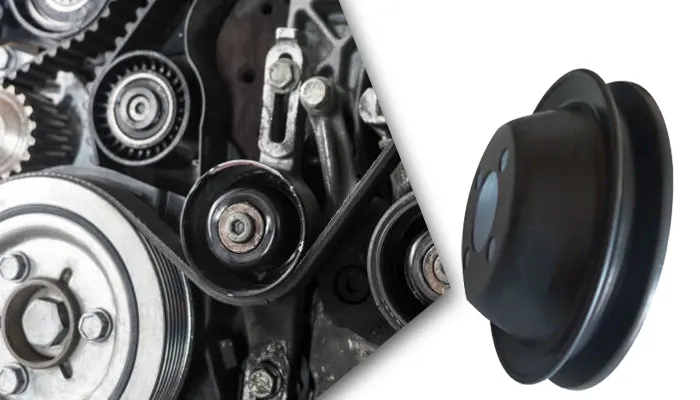

Automotive V Belt Pulley

Crankshaft Pulley

Motor Pulley

Power Steering Pump (Oil Pump) Pulley

Tension Idler Pulley

Water Pump Pulley

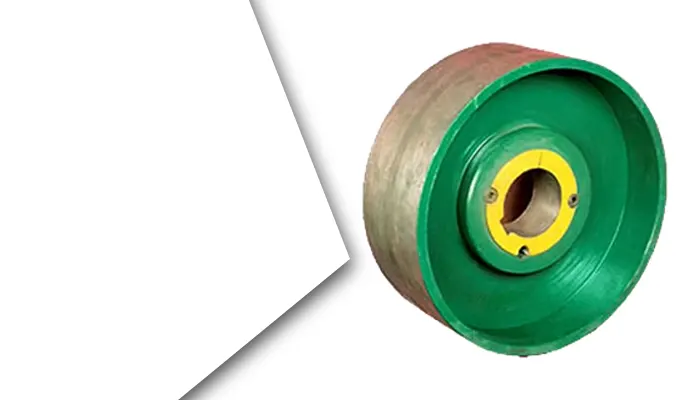

Agricultural Pulley

Agricultural Pulley

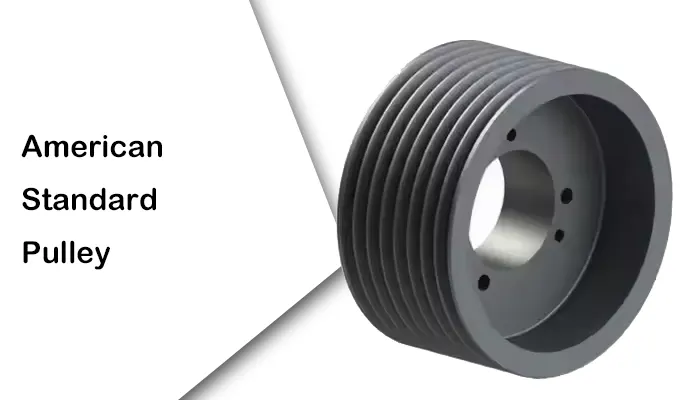

American Standard QD Taper Bushed Sheaves

3V Standard QD Sheaves

5V Standard QD Sheaves

8V Standard QD Sheaves

A/B QD Sheaves

C QD Sheaves

AK/2AK/2AKH Pilot Bore Sheaves

BK/2BK/3BK/BKH/2BKH/3BKH Pilot Bore Sheaves

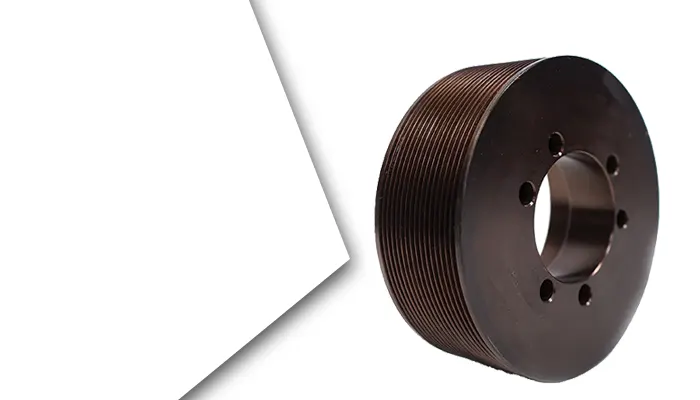

Poly-V Sheave

Variable Speed Sheave

European Standard TB Taper Bushed Pulleys

SPZ Standard V-Pulleys

SPA Standard V-Pulleys

SPB Standard V-Pulleys

SPC Standard V-Pulleys

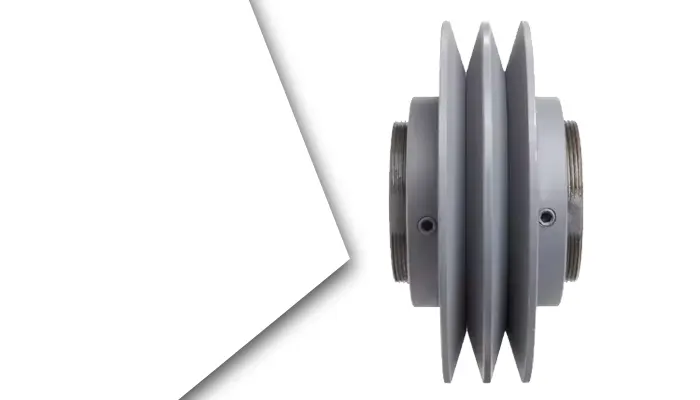

Adjustable Speed V Belt Pulley

Flat Belt Pulleys for Taper Bushes

Timing Belt Pulleys

European Standard Timing Pulley

Pilot Bore Series Timing Pulleys

Pilot Bore L Series Timing Pulleys

Pilot Bore XH Series Timing Pulleys

Pilot Bore XL Series Timing Pulleys

Pilot Bore XXH Series Timing Pulleys

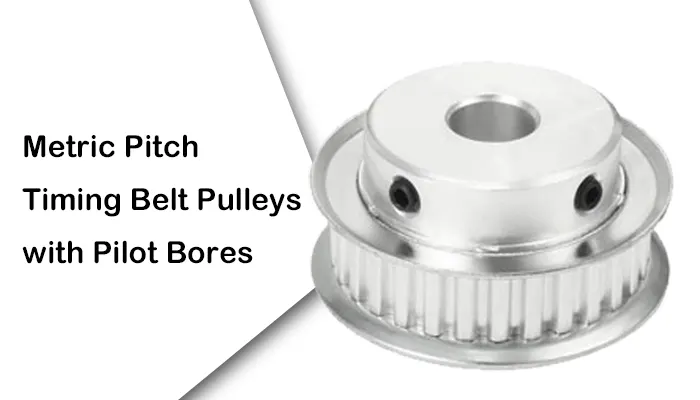

Metric Pitch Timing Belt Pulleys with Pilot Bores

Timing Belt Pulleys for Taper Bushes

Timing Belt Pulleys for Taper Bushes L050

Timing Belt Pulleys for Taper Bushes L075

Timing Belt Pulleys for Taper Bushes L100

Timing Belt Pulleys for Taper Bushes H100

Timing Belt Pulleys for Taper Bushes H150

Timing Belt Pulleys for Taper Bushes H200

Timing Belt Pulleys for Taper Bushes H300

HTD Timing Belt Pulleys

HTD Timing Belt Pulleys for Taper Bushes

HTD Timing Belt Pulleys with Pilot Bores

Metric Pitch Timing Belt Pulleys

Metric Pitch Timing Pulleys T2.5

Metric Pitch Timing Pulleys T5

Metric Pitch Timing Pulleys T10

Metric Pitch Timing Pulleys for AT Belts

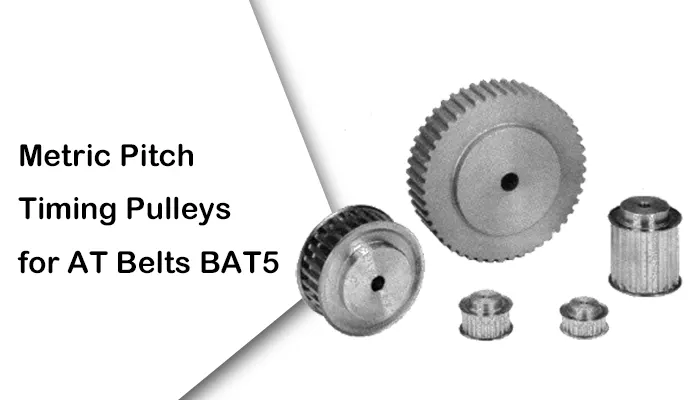

Metric Pitch Timing Pulleys for AT Belts BAT5

Metric Pitch Timing Pulleys for AT Belts BAT10

American Standard Timing Pulley

XL 1/5” Pitch Timing Pulleys

L 3/8” Pitch Timing Pulleys

H 1/2‘' Pitch Timing Pulleys

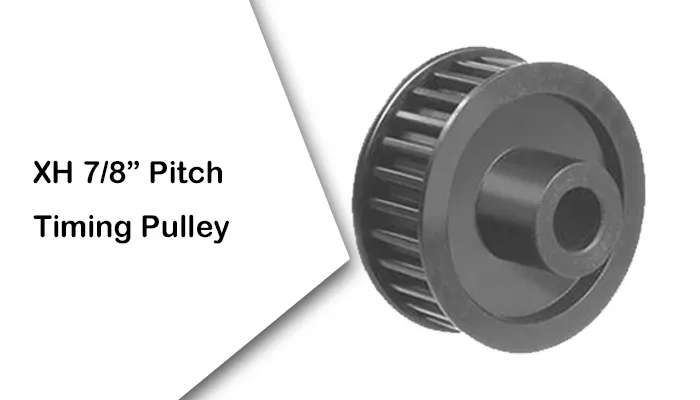

XH 7/8” Pitch Timing Pulleys

Toothed Bars for Timing Pulleys

Standard Toothed Bars XL 1/5 L 3/8

Standard Toothed Bar BAT 5 & BAT10

Metric Pitch Standard Toothed Bars T-2.5 & T-5 & T10

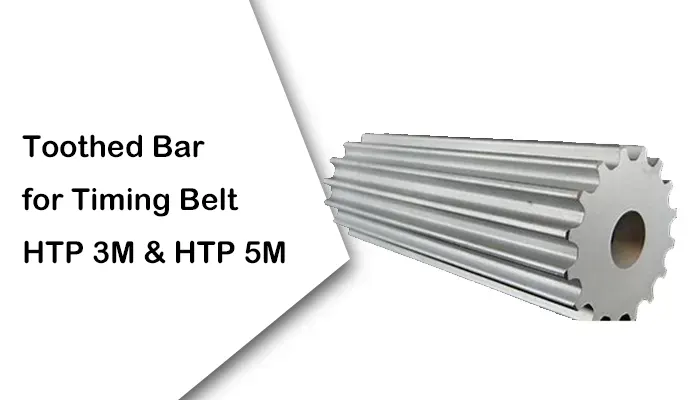

Toothed Bar for Timing Belt HTP 3M & HTP 5M

Resources Download

Belt Pulley Functions and Working Principles

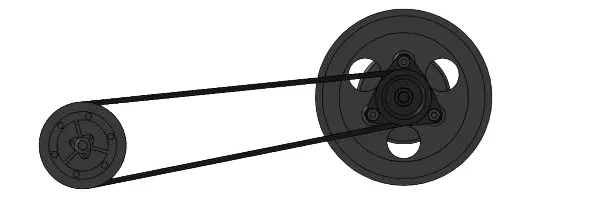

Belt pulleys, as the core components in mechanical transmission systems, are widely used in industrial equipment, automotive engines and agricultural machinery. Its core function is to transfer power through belts or chains, achieving speed regulation and torque distribution among different shafts. Whether it is the drive pulleys or the driven pulleys, the design of the pulley directly affects the transmission efficiency and the stability of the equipment.

The Core Function of the Pulley

Power transmission: The pulley transmits power from the driving shaft to the driven shaft through friction or meshing. For example, in a car engine, the drive sheaves are connected to the crankshaft and drive the generator, water pump and other accessories through a belt to ensure the coordinated operation of the system.

Speed regulation: By changing the diameter ratio of the pulley (i.e., the transmission ratio), the rotational speed of the output shaft can be adjusted. When large-diameter drive wheels are paired with small-diameter driven wheels, the output rotational speed increases. Conversely, reduce the rotational speed and increase the torque.

Direction conversion: In complex machinery, the combination of multiple sets of pulleys can change the direction of power transmission to meet the requirements of different spatial layouts.

Analysis of Working Principle

The operation of the pulley is based on the principle of friction transmission or meshing transmission:

Friction drive: V-belts or flat belts transmit power through friction with the wheel grooves. When the Drive Pulleys rotate, the belt is driven by friction, which in turn drives the driven pulleys. This type of transmission structure is simple, but it is necessary to ensure the tension of the belt to avoid slippage.

Meshing transmission: The Timing Belts mesh precisely with the gear teeth to achieve slip-free transmission, which is suitable for high-precision equipment such as printers and CNC machine tools.

Belt Pulley Materials Compared: Cast Iron, Steel, and Aluminum

When selecting belt pulleys for industrial machinery, the choice of material significantly impacts performance, durability, and cost. This guide compares the most common pulley materials—cast iron, steel, and aluminum—to help you make an informed decision for applications such as conveyor systems, manufacturing equipment, and power transmission setups.

| Material | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Cast Iron | – Excellent vibration damping (reduces noise). – High wear resistance. – Cost-effective for heavy-duty applications. |

– Heavy weight (may increase bearing load). – Prone to corrosion if uncoated. – Lower tensile strength than steel. |

Heavy machinery, crushers, mixers, and high-torque industrial pulleys. |

| Steel | – Superior strength and durability. – Resistant to high temperatures. – Suitable for high-speed applications. |

– Higher cost than cast iron or aluminum. – Susceptible to rust if not treated. – Heavier than aluminum. |

High-speed drive pulleys, compressors, engines, and transmission pulleys requiring precision. |

| Aluminum | – Lightweight (reduces inertia and energy consumption). – Corrosion-resistant (ideal for humid environments). – Easy to machine. |

– Lower strength than steel or cast iron. – More prone to wear under heavy loads. – Higher material cost than cast iron. |

Lightweight machinery, HVAC systems, food processing, and belt drive pulleys where speed and efficiency are critical. |

Premium Drive Pulleys for Reliable Performance

At GBC, we supply high-quality Drive Pulleys engineered for strength, stability, and long-term efficiency. Our pulleys are manufactured with robust materials and excellent craftsmanship meant to minimise wear and increase power transfer accuracy under harsh industrial and commercial settings.

Every pulley we provide is precision-balanced to guarantee smooth rotation and less belt slippage. Whether for motors, conveyors, or bespoke applications, we customise solutions to match your precise operational needs.

Our staff knows the need for surface finish and alignment. Our Drive Pulleys are made of premium-grade steel and machined to exact tolerances to guarantee consistent load handling and improved system performance.

From heavy-duty applications to smaller-scale machinery, we offer pulley solutions that support maximum grip and low maintenance. Each unit is tested to meet Australian industry standards, giving you peace of mind in every rotation.

Trusted by engineers and operators across Australia, GBC is more than a supplier. We’re your partner in reliable mechanical solutions.

Built for performance. Designed to last. Powered by Australia Drive.

Contact Us Now for Belt Pulleys Price

We are the sales agency of Ever – power Group in Australia, specializing in high-quality belt pulley products.

At present, our belt pulleys have been widely covered in states such as New South Wales, Victoria and Queensland. In major cities such as Sydney, Melbourne, Brisbane, Adelaide and Perth, we have established a stable and complete supply and sales service system, providing reliable power transmission solutions for local enterprises in various fields including industry and commerce, and facilitating the steady development of all industries.