Bucket elevators are commonly used material conveying equipment and are widely applied in various industries. To ensure the safety of the staff, it is necessary to formulate a complete set of operation procedures and precautions. The following are the safety operation procedures and precautions for bucket elevators.

Operating Procedures for Bucket Elevators

1. Preparations before operation

(1) Operators must be familiar with the structure, performance and operation methods of bucket elevators, receive professional training and hold certificates to work.

(2) Confirm whether the power supply of the bucket elevator is properly connected and there is no leakage or abnormal situation.

(3) Check whether the conveying channel of the bucket elevator is unobstructed and confirm that there is no blockage or foreign object.

2. Start and stop of bucket elevators

(1) The operator must observe and ensure that there is no one in the working area and no abnormal conditions before starting the bucket elevator.

(2) After starting the bucket elevator, observe the operation of the machine to ensure its normal operation, and pay attention to the working status of the sensors and monitoring equipment.

(3) During the operation of the bucket elevator, it must not be stopped, started or the running direction changed at will. It can only be carried out after reasonable planning and preparation.

(4) When stopping the bucket elevator, the switch should be set to the stop position to ensure that the equipment has completely come to a stop before conducting inspection and maintenance.

3. Maintenance and care of bucket elevators

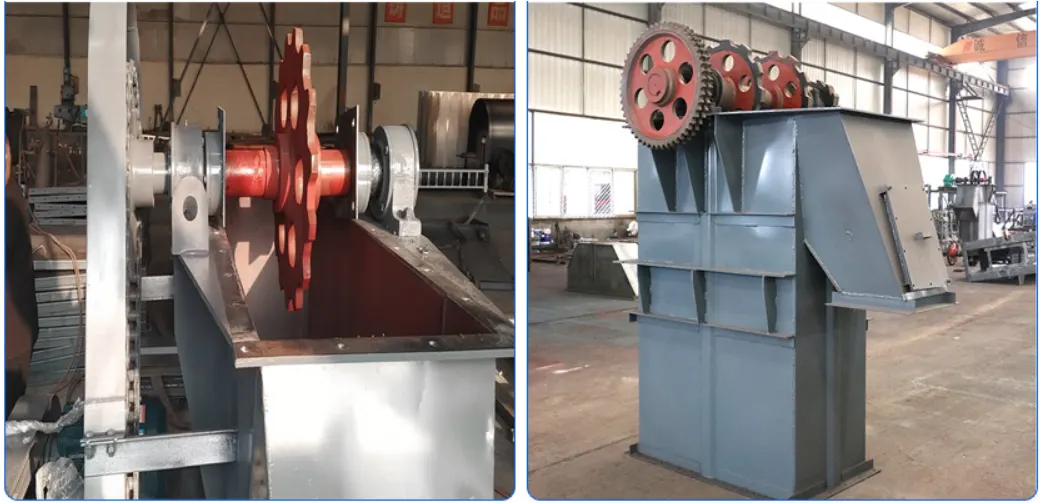

(1) Regularly inspect the main components of the bucket elevator, including sprockets, bearings, motors, etc., and replace worn or damaged parts in a timely manner.

(2) Regular maintenance of bucket elevators includes lubrication, cleaning, and tightening of bolts, etc., to keep the equipment in good operating condition.

(3) Regularly conduct a comprehensive inspection of the bucket elevator, including checking the integrity and reliability of the protective devices, as well as the working conditions of the sensors and monitoring equipment, etc.

(4) When maintaining and servicing the bucket elevator, the power supply must be cut off, and obvious warning signs should be set up on the relevant equipment and in the working area to prevent other personnel from approaching.

Precautions for Bucket Elevators

1. It is strictly prohibited for operators to touch the moving parts of the bucket elevator, including chains, bucket elevator sprockets and drive belts, etc., to avoid injury.

During the operation of the bucket elevator, it is strictly prohibited to insert hands or tools into the feeding or discharging ports of the elevator.

3. The power supply of the bucket elevator must be reliably grounded to reduce the risk of leakage and electric shock.

4. The electrical control system of the bucket elevator must comply with relevant safety standards and undergo regular inspection and maintenance.

Before starting to operate the bucket elevator, it is necessary to clear the conveying channel to prevent debris from falling into the elevator, so as to avoid blocking and damaging the equipment.

6. During the operation of the bucket elevator, if abnormal sounds, vibrations, leakage of electricity or other situations occur, the machine should be stopped immediately for inspection and the faults should be eliminated in a timely manner.

7. The maintenance and upkeep of bucket elevators must be carried out by personnel who have received professional training to ensure correct and safe operation.

8. When using a bucket elevator, the properties, humidity and temperature of the materials should be controlled to avoid excessive or unstable materials exerting pressure on the equipment, thereby affecting safety and normal operation.

9. Regular maintenance of bucket elevators should be carried out, including cleaning the conveying channels, inspecting the operation of the equipment, and replacing worn parts, etc., to ensure the safety and normal operation of the equipment.

10. When operating the bucket elevator, one should strictly follow the operating procedures. It is strictly forbidden to stop, start or change the running direction at will to ensure the safety and stable operation of the equipment.

By adhering to the operation procedures and precautions of bucket elevators, the safety performance of the equipment can be effectively enhanced and the safety of the staff can be guaranteed. Meanwhile, regularly inspect and maintain the bucket elevator, promptly eliminate faults, and extend the service life of the equipment.