I. Introduction

Bevel gears, as a key transmission component, are widely used in mechanical systems where the transmission direction needs to be changed while maintaining the intersection of the axes. They achieve power transmission through the meshing of gears, ensuring the efficient operation of mechanical devices. Straight bevel gears and spiral bevel gears are the two main types of bevel gears, each with its unique design features and applicable scenarios. This article aims to help readers make the best choice based on project requirements through comparative analysis. This article aims to provide engineers and project decision-makers with a comprehensive comparison between spur bevel gears and spiral bevel gears, so as to select the most suitable gear type based on specific project requirements.

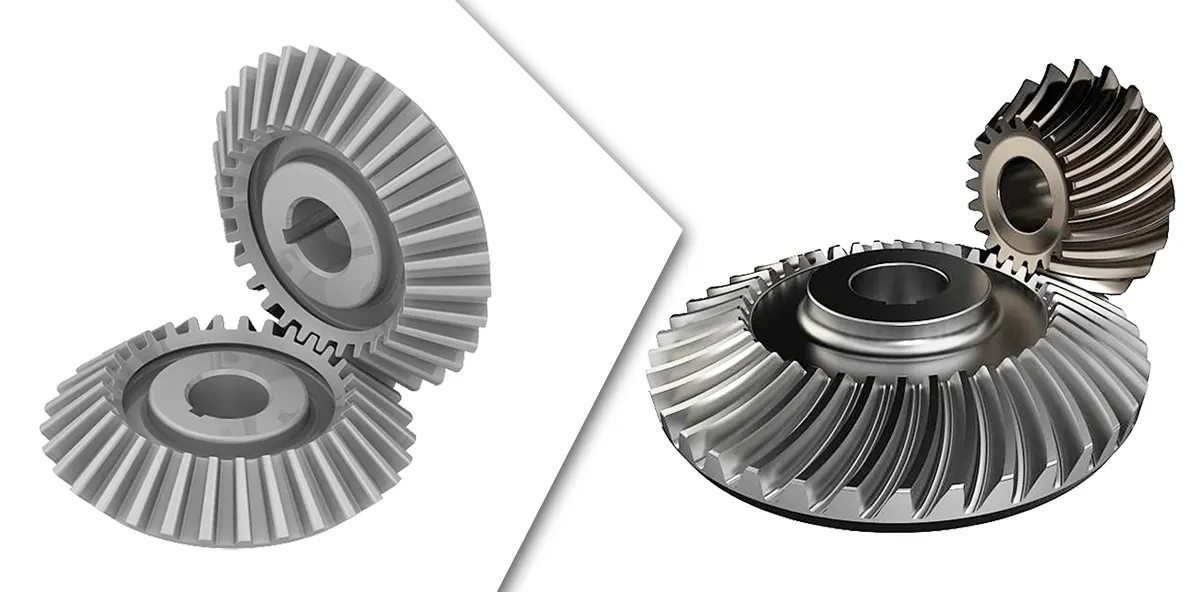

II Overview of Straight Bevel Gears

The tooth profile of spur bevel gears is straight and they are suitable for intersecting shaft transmission. Its design is simple, easy to understand and manufacture.

Advantages

It is easy to manufacture and low in cost

It is easy to install and debug

It is suitable for low-speed and light-load applications

Disadvantage

It makes a lot of noise when running at high speed

Strong vibration affects the smoothness of transmission

The efficiency is relatively low

Typical specification parameters

The gear ratio is determined based on the transmission requirements

module: Determines the size and strength of the gear

Materials: Commonly used are cast iron, steel, etc

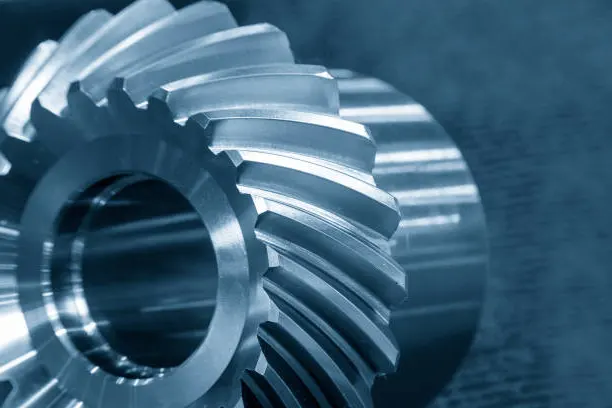

III. Overview of Spiral Bevel Gears

The tooth profile of spiral bevel gears is curved and involute, which makes the gear meshing more stable. Its design is complex, but its performance is superior.

Advantages

It operates smoothly with low noise

It has a strong load-bearing capacity and is suitable for high-load applications

It has high durability and a long service life

Disadvantage

It is complex to manufacture and costly

The alignment requirements are strict and the installation and commissioning are difficult

It may generate axial thrust, and additional support structures need to be designed

Introduction to Variants

Zero-degree spiral bevel gears are a variant of spiral bevel gears. Their tooth profile is close to that of straight teeth but retains some characteristics of spiral teeth, making them suitable for specific applications.

IV. Comparison between Spur Gears and Spiral Bevel gears

Performance comparison

Efficiency: Spiral bevel gears are usually higher

Noise: Spiral bevel gears are lower

Vibration: Spiral bevel gears are more stable

Service life: Spiral bevel gears have a longer lifespan

Manufacturing and cost comparison

The process difficulty is higher for spiral bevel gears

Material consumption: The two are comparable, but the spiral bevel gear may increase slightly due to its complex design

Overall cost: Spiral bevel gears are higher

Differences in applicable scenarios

For low speed and light load: straight bevel gears

High speed, high load: spiral bevel gears

Key Differences Table

| Characteristic | Straight Bevel Gear | Spiral Bevel Gear |

| Tooth Profile | Straight line | Curved (involute) |

| Noise Level | High | Low |

| Vibration | Intense | Smooth |

| Efficiency | Relatively Low | Relatively High |

| Cost | Low | High |

| Applicable Scenario | Low-speed, light-load applications | High-speed, heavy-load applications |

| Manufacturing Complexity | Simple | Complex |

| Installation & Alignment Requirement | Easy; less stringent alignment needed | Difficult; strict alignment required |

| Axial Thrust | Generally none (or minimal) | May generate significant axial thrust, requiring additional support structures |

| Durability & Lifespan | Shorter | Longer |

V. A guide to choosing the best gears for your project

Project Requirements assessment

Speed: Determine the maximum rotational speed of the transmission system

Load: Evaluate the maximum load of the transmission system

Noise requirements: Consider the tolerance of the working environment for noise

Budget: Determine the acceptable cost range for the project

Consideration of selection factors

Environmental conditions: such as temperature, humidity, corrosiveness, etc

Maintenance requirements: Consider the ease of maintenance and repair costs of the gears

Precision requirements: Select the appropriate gear type based on the precision requirements of the transmission system

Decision-making steps

- Determine the shaft Angle and transmission direction

- Evaluate load and speed requirements

- Consider the requirements for noise and vibration

- Select the appropriate gear type based on the budget

- Verify the compatibility and installation conditions of the gears

Common Error avoidance

Ignore axial thrust: Spiral bevel gears may generate axial thrust, and an appropriate support structure needs to be designed

Lubrication issue: Ensure that the gears are adequately lubricated to reduce wear and noise

The alignment of helical bevel gears is inaccurate: The alignment requirements for helical bevel gears are strict, and it is necessary to ensure precise installation

VI. Practical Application Cases

The application of spur bevel gears

Manual tools: such as drilling machines, sawing machines, etc

Simple machinery: such as conveyor belts, elevators, etc

Agricultural equipment: such as tractors, harvesters, etc

The application of spiral bevel gears

Automotive differential: It enables differential transmission between the left and right wheels

High-precision transmission systems for machine tools such as milling machines and grinders

Aviation equipment: such as aircraft landing gear, engine transmission systems, etc

Case Analysis

In the design of differentials, a certain automobile manufacturer initially adopted spur bevel gears. However, when operating at high speeds, the differential generates significant noise and vibration, which affects the driving experience. Later, the manufacturer switched to spiral bevel gears, successfully reducing noise and vibration, and enhancing the smoothness and durability of transmission.

VII. Conclusion

Straight bevel gears and spiral bevel gears each have their unique design features and applicable scenarios. Straight bevel gears are easy to manufacture and have a low cost, making them suitable for low-speed and light-load applications. Spiral bevel gears operate smoothly, generate low noise and have strong load-carrying capacity, making them suitable for high-speed and high-load applications. When choosing the type of gear, a comprehensive assessment should be conducted based on the project requirements. With the development of advanced materials and 3D printing technology, gear manufacturing will become more efficient, precise and personalized. In the future, we can look forward to more innovative gear designs to meet the constantly changing demands of mechanical transmission.