Specifications of C2052/2052 Double Pitch Carrier Roller Chain Sprocket

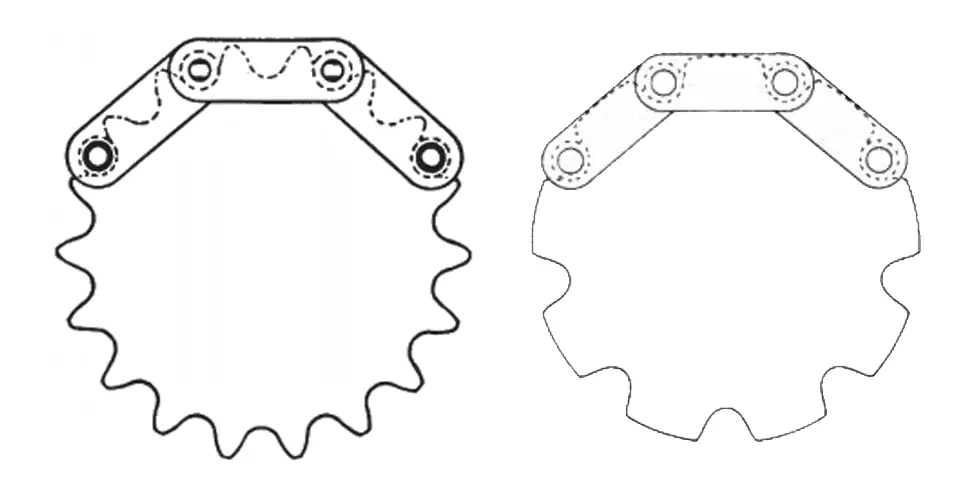

C2052/2052 Double Pitch Carrier Roller Chain Sprocket is a type of sprocket commonly used in transmission systems. It features a carrier roller that helps to guide the chain and ensure smooth operation.

| Sprocket Size | Tooth Count | Outside Diameter | Stock Bore | Maximum Bore | Length Thru Bore | Weight |

|---|---|---|---|---|---|---|

|

2052A12

|

12 | 5.420" | 23/32" | -- | -- | 1.58 LBS |

|

2052A13

|

13 | 5.820" | 23/32" | -- | -- | 1.82 LBS |

|

2052A14

|

14 | 6.230" | 23/32" | -- | -- | 2.28 LBS |

|

2052A15

|

15 | 6.630" | 23/32" | -- | -- | 2.46 LBS |

|

2052A16

|

16 | 7.030" | 23/32" | -- | -- | 2.88 LBS |

|

2052A17

|

17 | 7.440" | 23/32" | -- | -- | 3.28 LBS |

|

2052A18

|

18 | 7.840" | 23/32" | -- | -- | 3.64 LBS |

|

2052A19

|

19 | 8.240" | 23/32" | -- | -- | 4.12 LBS |

|

2052A20

|

20 | 8.640" | 23/32" | -- | -- | 4.72 LBS |

|

2052A21

|

21 | 9.040" | 23/32" | -- | -- | 5.08 LBS |

|

2052A22

|

22 | 9.440" | 23/32" | -- | -- | 5.20 LBS |

|

2052A23

|

23 | 9.850" | 15/16" | -- | -- | 5.84 LBS |

|

2052A24

|

24 | 10.250" | 15/16" | -- | -- | 6.70 LBS |

|

2052A25

|

25 | 10.650" | 15/16" | -- | -- | 7.54 LBS |

|

2052A26

|

26 | 11.050" | 15/16" | -- | -- | 8.24 LBS |

|

2052A28

|

28 | 11.840" | 15/16" | -- | -- | 8.70 LBS |

|

2052A30

|

30 | 12.640" | 15/16 | -- | -- | 9.92 LBS |

|

2052B8

|

8 | 3.770" | 5/8" | 1-19/32" | 1" | 1.38 LBS |

|

2052B9

|

9 | 4.190" | 5/8" | 1-25/32" | 1" | 1.92 LBS |

|

2052B10

|

10 | 4.600" | 5/8" | 2" | 1" | 2.30 LBS |

|

2052B11

|

11 | 5.010" | 5/8" | 2" | 1" | 2.54 LBS |

|

2052B12

|

12 | 5.420" | 3/4" | 2" | 1-1/4" | 3.20 LBS |

|

2052B13

|

13 | 5.820" | 3/4" | 2" | 1-1/4" | 3.48 LBS |

|

2052B14

|

14 | 6.230" | 3/4" | 2" | 1-1/4" | 3.88 LBS |

|

2052B15

|

15 | 6.630" | 3/4" | 2-1/4" | 1-1/4" | 4.46 LBS |

|

2052B16

|

16 | 7.030" | 3/4" | 2-1/4" | 1-1/4" | 4.80 LBS |

|

2052B17

|

17 | 7.440" | 3/4" | 2-1/4" | 1-1/4" | 5.34 LBS |

|

2052B18

|

18 | 7.840" | 3/4" | 2-1/4" | 1-1/4" | 5.64 LBS |

|

2052B19

|

19 | 8.240" | 3/4" | 2-1/4" | 1-1/4" | 6.04 LBS |

|

2052B20

|

20 | 8.640" | 3/4" | 2-1/4" | 1-1/4" | 6.48 LBS |

|

2052B21

|

21 | 9.040" | 3/4" | 2-1/4" | 1-1/4" | 7.00 LBS |

|

2052B22

|

22 | 9.440" | 3/4" | 2-1/4" | 1-1/4" | 7.30 LBS |

|

2052B23

|

23 | 9.850" | 1" | 2-3/4" | 1-1/4" | 8.66 LBS |

|

2052B24

|

24 | 10.250" | 15/16" | 2-3/4" | 1-1/4" | 9.32 LBS |

|

2052B25

|

25 | 10.650" | 15/16" | 2-3/4" | 1-1/4" | 10.30 LBS |

|

2052B26

|

26 | 11.050" | 15/16" | 2-3/4" | 1-1/4" | 11.00 LBS |

|

2052B28

|

28 | 11.840" | 15/16" | 2-3/4" | 1-1/4" | 11.70 LBS |

|

2052B30

|

30 | 12.640" | 15/16" | 2-3/4" | 1-1/4" | 12.90 LBS |

Definition and Basic Structure

C2052 Double Pitch Sprocket refers to a sprocket with a larger pitch than standard sprockets. It consists of teeth positioned at a greater distance from each other, allowing for better load distribution and increased load capacity. The carrier roller, located between the teeth, acts as a guide for the chain.

Main Features of C2052/2052 Double Pitch Carrier Roller Chain Sprocket

- Greater Tooth Spacing: The larger pitch provides more space between the teeth, allowing for smoother engagement with the chain.

- Higher Load Capacity: The design of the sprocket and the presence of the carrier roller enable it to withstand higher loads.

- Smooth Operation: The carrier roller ensures smooth movement of the chain, reducing friction and noise.

Material Selection for C2052/2052 Double Pitch Carrier Roller Chain Sprocket

Double pitch sprockets can be made from different materials depending on the specific requirements of the application. The available material options include carbon steel, alloy steel, and stainless steel.

Carbon Steel: Known for its strength and affordability, carbon steel is commonly used for standard applications.

Alloy Steel: Alloy steel offers enhanced strength and durability, making it suitable for demanding environments or heavy-duty applications.

Stainless Steel: Stainless steel provides excellent corrosion resistance, making it ideal for applications where exposure to moisture or chemicals is a concern.

Manufacturing Process of C2052/2052 Double Pitch Carrier Roller Chain Sprocket

- Raw Material Preparation: The process starts with selecting high-quality materials that meet the required specifications.

- Forging or Casting: The selected material is either forged or cast to shape it into the desired sprocket form.

- Machining: The sprocket undergoes precision machining to achieve the correct dimensions and tooth profiles.

- Tooth Rolling: The teeth are formed using a rolling process, ensuring high precision and strength.

- Heat Treatment: The sprocket is subjected to heat treatment to enhance its hardness and durability.

- Surface Treatment: Various surface treatments like plating or coating are applied to improve corrosion resistance and aesthetics.

- Quality Inspection: The finished sprocket undergoes rigorous quality checks to ensure it meets the required standards.

Customization Services

We offer customization services for C2052/2052 Double Pitch Carrier Roller Chain Sprockets to meet specific requirements:

- Material Selection: Customers can choose the material that best suits their application needs.

- Tooth Profile Design: We can assist in designing the optimal tooth profile for efficient chain engagement and performance.

- Bore Size and Keyway: The bore size and keyway can be customized to match the shaft requirements of the application.

Sprockets Supplier in Australia

GBC serves as the Australian sales agent for Ever-power Group, a leading manufacturer of high-quality industrial products. Our extensive range includes the C2052/2052 Double Pitch Carrier Roller Chain Sprocket, designed for optimal performance in various applications. This sprocket is engineered to provide reliable operation and longevity, making it an excellent choice for industries requiring durable and efficient solutions.

In addition to our standard sprockets, we offer customized solutions tailored to meet specific customer requirements. We invite our clients to provide drawings or samples for non-standard designs, ensuring that we can deliver the exact product they need.

Additional information

| Edited by | Sylvia |

|---|