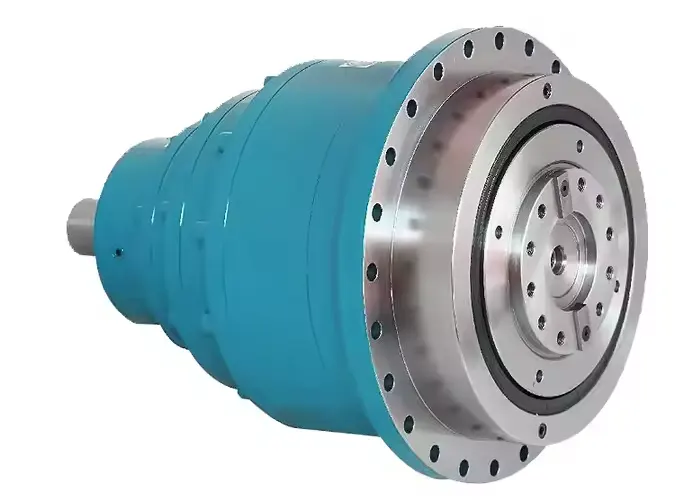

Planetary Gearboxes

Cost-Effective and Customized Solutions

High efficiency, durability and precision for a wide range of industries

Planetary Reduction Gearbox for Sale

Hot Sale Planetary Reducers at GBC

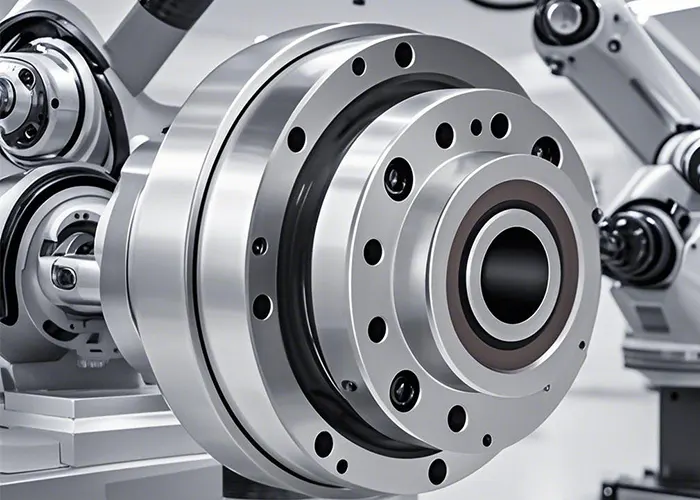

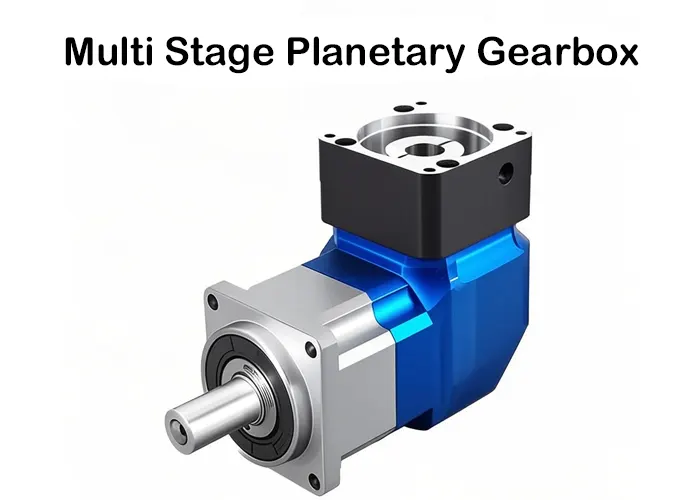

Planetary Reducer Gearbox by Structure

Single Stage Planetary Gearbox

Multi Stage Planetary Gearbox

Planetary Reducers by Applications

Industrial Planetary Gearbox

Automotive Planetary Gearbox

Planetary Gearbox for Aerospace

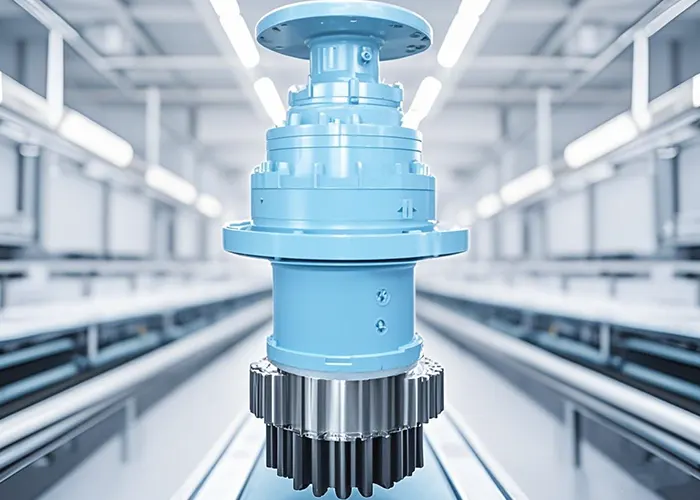

Planetary Gear Drive by Mounting Type

Flange Mounted Planetary Gearbox

Foot-Mounted Planetary Gearbox

Shaft Mounted Planetary Gearbox

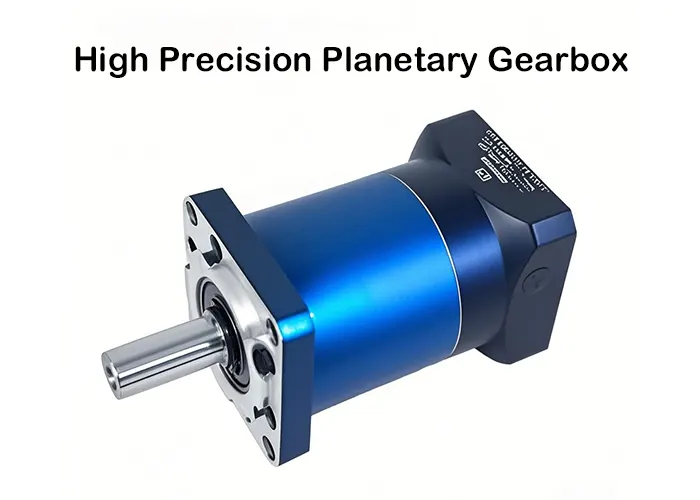

Planetary Speed Reducers by Precision Grade

Standard Precision Planetary Gearbox

High Precision Planetary Gearbox

Planetary Drive Gearboxes by Ratios

Low Reduction Ratio Planetary Gearbox (1:3 to 1:10)

Medium Reduction Ratio Planetary Gearbox (1:10 to 1:100)

High Reduction Ratio Planetary Gearbox (Above 1:100)

Planetary Gearbox Reducers by Load Capacity

Light Duty Planetary Gearbox

Medium Duty Planetary Gearbox

Heavy Duty Planetary Gearbox

Planetary Gear Reduction Boxes by Material or Lubrication Method

Steel Gear Type Planetary Gearbox

Composite Type Planetary Gearbox

Oil Lubricated Planetary Gearbox

Grease Lubricated Planetary Gearbox

Key Benefits of Planetary Gearboxes

Cost-effective

Quality performance at a reasonable price to reduce your purchasing costs.

Efficient Transmission

Up to 98% transmission efficiency, suitable for both general and customized applications.

Customization

From design to production, exclusive solutions to meet unique needs.

Durable

Rigorous testing to ensure long-term stable operation.

Planetary Reduction Gearbox Applications

Common Planetary Gearbox Failure and Maintenance Strategies

Planetary Gearboxes are widely used in industrial automation, wind power generation, heavy machinery and other fields due to their compact structure, high torque transmission efficiency and multi-stage reduction capabilities. However, complex working conditions are prone to cause faults such as bearing wear, gear failure, and oil leakage, leading to equipment downtime and increased maintenance costs.

Common Planetary Gearbox Failure Types and Diagnostic Methods

|

Failure Type |

Failure Characteristics |

Diagnostic Methods |

|

Gear Tooth Breakage/Cracks |

Abnormal vibration, metal debris, abnormal fluctuations in meshing frequency |

Vibration spectrum analysis: Monitor changes in meshing frequency and its harmonics; Envelope demodulation analysis: Identify periodic impact components |

|

Bearing Wear/Pitting |

Abnormal temperature rise, high-frequency noise, increased radial vibration |

Temperature monitoring: Real-time tracking of bearing zone temperature; Envelope demodulation analysis: Extract bearing fault characteristic frequencies |

|

Lubricant Oil Leakage |

Oil stains at the gearbox joints, oil level drop, lubrication failure |

Visual inspection: Locate leakage points; Pressure testing: Verify the pressure resistance of seals |

|

Planet Carrier Eccentricity |

Output torque fluctuations, increased low-frequency vibration |

Shaft center trajectory analysis: Evaluate the motion trajectory of the planet carrier; Phase analysis: Compare the phase difference between input and output shafts |

|

Tooth Surface Pitting/Spalling |

Continuous noise, vibration energy concentrated at meshing frequency |

Sideband analysis: Detect sideband components on both sides of the meshing frequency; Refined spectrum analysis: Improve resolution of low-amplitude fault signals |

Planetary Gearboxes Maintenance Strategies and Preventive Maintenance

Repair of broken teeth/cracks in gearsStop the machine immediately and disassemble the faulty component. Use a three-coordinate measuring instrument to test the shape and position tolerance of the tooth surface. If the crack depth is ≤ 10% of the tooth width, laser cladding technology can be adopted for repair. If the limit is exceeded, replace the gear set. When assembling, the side clearance of the gear pair needs to be calibrated to 0.05-0.15mm and coated with anti-micro-pitting lubricant. |

Bearing maintenance planReplace grease-lubricated bearings regularly (every 5000 hours), and for oil-lubricated bearings, monitor the viscosity index of the oil (ISO VG 320). When installing, the hydraulic press-fitting method is adopted to control the interference fit. The recommended fit tolerance between the outer ring of the bearing and the seat hole is H7. |

Upgrade of the sealing systemFor the dynamic sealing part, a double-lip skeleton oil seal (NBR material) is adopted instead, and a labyrinth sealing structure is added. The static sealing surface is coated with Loctite 587 flat sealant, and after curing, its pressure resistance capacity can reach 25MPa. |

Planetary carrier calibration processThe coaxiality of the input shaft and the planet carrier was adjusted using a laser alignment instrument, with the error controlled within 0.02mm. After assembly, a no-load running-in test was conducted to monitor the effective value of the vibration velocity (≤4.5mm/s). |

Tooth surface strengthening treatmentThe new gears need to undergo carburizing quenching (HRC58-62) and superfinishing (surface roughness Ra≤0.4μm). During operation, extreme pressure additives (sulfur-phosphorus type) should be added regularly to enhance the anti-sticking ability of the tooth surface. |

Testimonials of GBC Planetary Gear Drive

Planetary Gear Reducer Manufacturers in Australia – GBC

GBC is the sales agent for the EverPower Group in Australia. As a key supplier of planetary gearboxes to one of Australia’s top 10 brands, we’re dedicated to delivering superior transmission solutions. Our planetary gearboxes, sold across New South Wales, Victoria, Queensland, and in cities like Sydney, Melbourne, Brisbane, Adelaide, and Perth, offer cost – effective options for general industry needs as well as high – end customization. They have a wide range of applications, including cranes, wind power, robots, and more. Additionally, we provide high – quality localization services to ensure swift responses and technical support. By choosing GBC, you get a reliable, durable, and efficient gearbox product. Contact us today to get a quote or customize your solution!