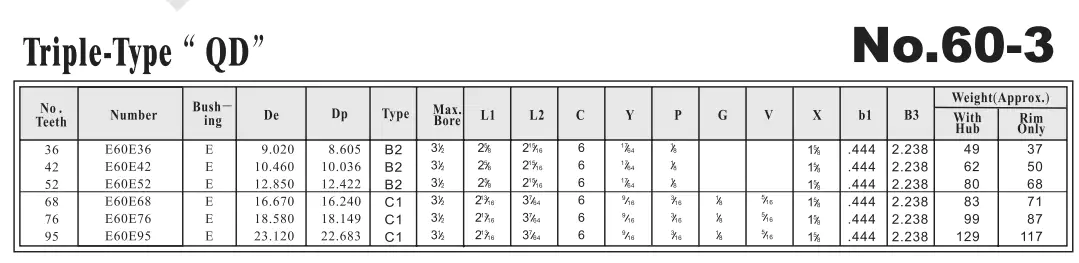

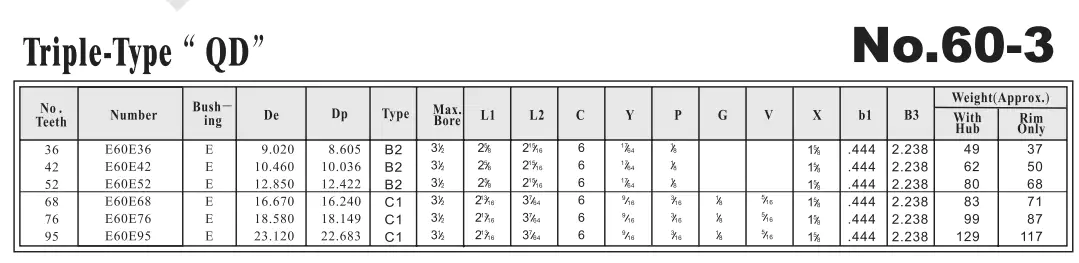

#60-3 3/4" Pitch QD Sprocket Specifications

QD Sprocket No.60-3 Triple Type is a variant of QD sprocket widely utilized in transmission systems. QD sprockets are crucial for power transmission, serving to transfer torque and rotational motion efficiently.

Definition and Basic Structure of QD Sprocket

A QD sprocket refers to a type of sprocket equipped with a quick disconnect (QD) bushing. This bushing facilitates the simple installation and removal of the sprocket without requiring extensive disassembly. The fundamental structure of a QD sprocket includes a hub, teeth, and the QD bushing.

Characteristics and Functions of QD Bushing

- Easy Installation: The QD bushing streamlines the installation process of the sprocket, saving valuable time and effort.

- High Load Capacity: Designed to bear heavy loads, QD bushings ensure reliable performance in rigorous applications.

- Standardized Design: QD bushings adhere to industry standards, guaranteeing compatibility with a range of shaft sizes.

- Compact Design: The compact nature of QD bushings enables space-efficient installations in confined areas.

- Low Maintenance Cost: Minimal maintenance requirements for QD bushings help reduce overall maintenance costs.

A notable advantage of QD bushings is their simplicity in installation and removal. This feature allows for quick and efficient sprocket replacements or adjustments, thus minimizing downtime and enhancing productivity.

Installation and Removal Process of QD Bushing

- Prepare Tools and Materials: Collect the necessary tools and materials, including a wrench and lubricant.

- Clean Shaft and Sprocket Surface: Ensure that both the shaft and sprocket surfaces are clean and free from contaminants.

- Position Sprocket: Place the sprocket onto the shaft, aligning the keyway or set screw holes appropriately.

- Install QD Bushing: Slide the QD bushing onto the shaft until it fits snugly.

- Secure Sprocket: Tighten the set screws or bolts on the QD bushing to firmly secure the sprocket.

- Check: Verify the installation for proper alignment and tightness to guarantee dependable operation.

Manufacturing Process of QD Sprocket

- Raw Material Preparation: Choose appropriate materials, such as steel, for producing QD sprockets.

- Cutting: Cut the raw material into the required shape and dimensions.

- Forging or Casting: Employ forging or casting processes to further refine the shape of the material.

- Machining: Utilize precision machining techniques to form the teeth and other essential features.

- Teeth Rolling: Roll the teeth to ensure they have accurate profiles that mesh correctly with the chain.

- Heat Treatment: Implement heat treatment to improve the hardness and strength of the sprocket.

- Surface Treatment: Conduct surface treatments, like coating or plating, to enhance corrosion resistance.

- Quality Inspection: Perform comprehensive quality inspections to confirm that the sprocket meets established standards.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing top-quality sprockets and related products to meet the diverse needs of customers across various industries.

Introduction

QD Sprocket No.60-3 Triple Type is a type of QD sprocket that is commonly used in transmission systems. QD sprockets are an essential component in power transmission, providing a means to transfer torque and rotational motion.

Definition and Basic Structure of QD Sprocket

A QD sprocket is a type of sprocket that is designed with a quick disconnect (QD) bushing. The QD bushing allows for easy installation and removal of the sprocket without the need for extensive disassembly. The basic structure of a QD sprocket consists of a hub, teeth, and the QD bushing.

Characteristics and Functions of QD Bushing

- Easy Installation: The QD bushing simplifies the installation process of the sprocket, saving time and effort.

- High Load Capacity: QD bushings are designed to withstand heavy loads, ensuring reliable performance in demanding applications.

- Standardized Design: QD bushings are manufactured to meet industry standards, ensuring compatibility with various shaft sizes.

- Compact Design: The compact size of QD bushings allows for space-saving installations in tight spaces.

- Low Maintenance Cost: QD bushings require minimal maintenance, reducing overall maintenance expenses.

One of the key advantages of QD bushings is their ease of installation and removal. This feature allows for quick and efficient sprocket replacements or adjustments, minimizing downtime and maximizing productivity.

Installation and Removal Process of QD Bushing

- Prepare Tools and Materials: Gather the necessary tools and materials, including a wrench and lubricant.

- Clean Shaft and Sprocket Surface: Ensure that the shaft and sprocket surfaces are clean and free from dirt or debris.

- Position Sprocket: Position the sprocket on the shaft, aligning the keyway or set screw holes.

- Install QD Bushing: Slide the QD bushing onto the shaft, ensuring a snug fit.

- Secure Sprocket: Tighten the set screws or bolts on the QD bushing to secure the sprocket in place.

- Check: Inspect the installation for proper alignment and tightness to ensure reliable operation.

Manufacturing Process of QD Sprocket

- Raw Material Preparation: Select suitable materials, such as steel, for the manufacturing of QD sprockets.

- Cutting: Cut the raw material into the desired shape and size.

- Forging or Casting: Forge or cast the material to further refine its shape.

- Machining: Use precision machining techniques to create the teeth and other necessary features.

- Teeth Rolling: Roll the teeth to ensure accurate tooth profiles and proper meshing with the chain.

- Heat Treatment: Apply heat treatment to enhance the hardness and strength of the sprocket.

- Surface Treatment: Perform surface treatments, such as coating or plating, to improve corrosion resistance.

- Quality Inspection: Conduct thorough quality inspections to ensure the sprocket meets specified standards.

Frequently Asked Questions (FAQ)

- Q: What are the advantages of using a QD sprocket?

- Q: How do I install a QD bushing on a sprocket?

- Q: What is the manufacturing process of QD sprockets?

- Q: Can QD sprockets be used in high-load applications?

- Q: Are QD bushings interchangeable between different sprocket sizes?

A: The advantages of using a QD sprocket include easy installation and removal, high load capacity, standardized design, compact size, and low maintenance cost.

A: To install a QD bushing on a sprocket, follow these steps: prepare tools and materials, clean the shaft and sprocket surface, position the sprocket, install the QD bushing, secure the sprocket, and check the installation.

A: The manufacturing process of QD sprockets involves raw material preparation, cutting, forging or casting, machining, teeth rolling, heat treatment, surface treatment, and quality inspection.

A: Yes, QD sprockets are designed to withstand high loads, making them suitable for various heavy-duty applications.

A: QD bushings are manufactured to industry standards, allowing for interchangeability between different sprocket sizes within the compatible range.

Author: Miya

We offer a wide range of high-quality sprockets including the #60-3 3/4" Pitch QD Sprocket. Our products are designed to meet the highest standards, ensuring reliable performance in various applications. In addition to standard sprockets, we also provide custom non-standard products tailored to our customers' specifications. We welcome customers to reach out with drawings or samples for custom orders.

Additional information

| Edited by | Sylvia |

|---|