AH101339 Gathering Chain Drive Sprocket For John Deere Corn Head

The AH101339 Gathering Chain Drive Sprocket is designed specifically for use with various John Deere Corn Heads. It is compatible with models including the 1253A, 853A, and 854A Corn Heads, as well as the 655A, 453A, 454A, 653A, and 654A Heads. This sprocket ensures optimal performance and durability, making it an essential replacement part for efficient corn harvesting operations.

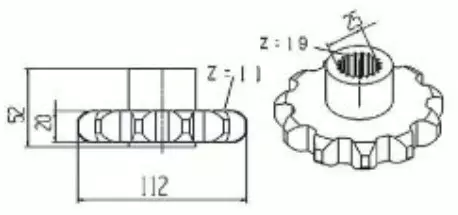

Parameters Of Gathering Chain Drive Sprocket

- Compatible with John Deere Header(s) 453A, 454A, 653A, 654A, 655A, 853A, 854A, 1253A

- Replaces John Deere OEM nos AH101339

- 11 Tooth

- 19 Splines Bore

- 1.720" Hub Length

- For RH Side gatherer chain

- All new, rebuilt and used tractor parts have a 5-year warranty

Features of AH101339 Gathering Chain Drive Sprocket

- Compatible with multiple John Deere Corn Head models, including 453A to 854A.

- 11 tooth design enhances efficiency in harvesting operations.

- 19 splines bore and 1.720" hub length ensure a precise fit.

- Specifically designed for the right-hand side gatherer chain.

- Comes with a 5-year warranty on all new, rebuilt, and used parts.

Installation Steps for AH101339 Gathering Chain Drive Sprocket

- Ensure the machine is turned off and properly secured before starting the installation.

- Remove the old gathering chain drive sprocket by unscrewing the bolts holding it in place.

- Inspect the area for any damage or wear before installing the new sprocket.

- Align the new AH101339 sprocket with the corresponding splines on the shaft, ensuring the 19 splines fit properly.

- Secure the sprocket with bolts, tightening them to the manufacturer's specifications.

- Reconnect the gatherer chain and check for proper alignment and functioning before operating the machine.

Manufacturing Process of AH101339 Gathering Chain Drive Sprocket

The manufacturing process of the AH101339 Gathering Chain Drive Sprocket involves several key steps:

- Design and Engineering: Initial designs are created using advanced CAD software to ensure precision.

- Material Selection: High-quality steel is chosen for durability and strength.

- Machining: The material is machined to form the sprocket shape, including the 11 teeth and 19 splines bore.

- Heat Treatment: The sprocket undergoes heat treatment to enhance hardness and wear resistance.

- Quality Control: Each sprocket is meticulously inspected for defects to meet OEM standards.

- Finishing: Finally, the sprocket is finished with a protective coating to prevent corrosion.

Agricultural Chains and Sprockets Supplier

GBC is the Australian sales agent for Ever-power Group and is one of the top ten sprocket suppliers in Australia. Our range of agricultural sprockets includes the AH101339 Gathering Chain Drive Sprocket designed specifically for John Deere Corn Heads. Our sprockets are compatible with various brands such as John Deere, New Holland, and Case-IH, making them suitable for combine harvesters, header attachments, corn headers, and grain elevators.

We pride ourselves on providing exceptional service to our clients, ensuring that all agricultural needs are met efficiently and effectively.

Agricultural Chains for Sale

In addition to the AH101339 Gathering Chain Drive Sprocket for John Deere Corn Head, we also offer high-quality agricultural chains for sale. Our chains are designed to meet the rigorous demands of farming equipment and ensure optimal performance. If you are interested in purchasing or would like to know more about our products, please contact us for further information.

Additional information

| Edited | Sylvia |

|---|

The AH101339 Gathering Chain Drive Sprocket is designed specifically for use with various John Deere Corn Heads. It is compatible with models including the 1253A, 853A, and 854A Corn Heads, as well as the 655A, 453A, 454A, 653A, and 654A Heads. This sprocket ensures optimal performance and durability, making it an essential replacement part for efficient corn harvesting operations.