Metric Bore Sprocket for ISO 10B Roller Chain (15.875mm Pitch)

Introducing our Metric Bore Sprocket, designed for ISO 606 and DIN 8187 10B Roller Chain with a 15.875mm pitch. This high-performance sprocket ensures durability and efficiency in various applications, making it an ideal choice for your machinery needs. GBC proudly offers high-quality Metric Bore Sprockets in Australia.

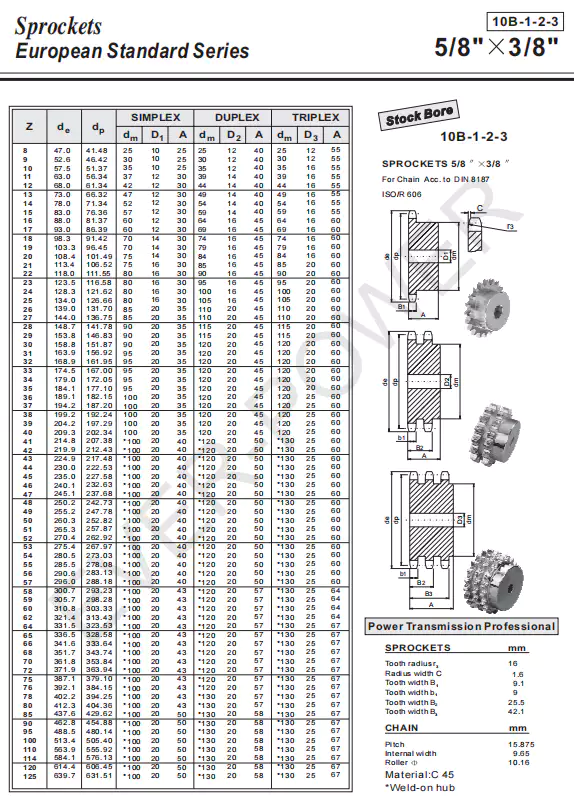

Specifications for Metric Bore Sprocket for ISO 10B Roller Chain (15.875mm Pitch)

A metric bore sprocket is specifically designed for use with ISO 10B roller chains, which have a pitch of 15.875mm. This type of sprocket is essential in many industrial applications, providing a reliable means of power transfer between rotating shafts. Its design ensures compatibility with standardized roller chains, making it a crucial component in various machinery setups.

Basic Structure of a Sprocket

A sprocket comprises several key components, including teeth, a bore, and sometimes keyways. The teeth interact with the chain's rollers to facilitate motion and power transmission. When customizing a sprocket, several important factors need to be taken into account:

-

- Material

The choice of material for the sprocket is dictated by its intended application. Common options include high carbon steel for strength, alloy steel for enhanced durability, or stainless steel for corrosion resistance in harsh environments.

-

- Tooth profile

The tooth profile is critical as it influences how well the sprocket meshes with the chain. Standard profiles such as ANSI and British standards are commonly used, ensuring effective engagement and minimizing wear.

-

- Number of teeth

The number of teeth on the sprocket plays a significant role in determining the speed and torque transmission ratio. A higher number of teeth typically results in lower speed and higher torque, while fewer teeth can produce the opposite effect.

-

- Dimensions

Dimensions like outer diameter and width are tailored to meet the specific demands of the application. Proper sizing is essential for ensuring optimal performance and compatibility with associated components.

-

- Bore

The bore is the central hole in the sprocket that secures it onto the shaft. Correct bore sizing is crucial for a tight fit, which helps prevent slippage during operation.

-

- Keyway

A keyway is a groove in the bore that allows for the insertion of a key. This component is vital for preventing rotational movement between the sprocket and the shaft, ensuring synchronized operation.

-

- Surface treatment

Surface treatments can significantly enhance the sprocket's durability, improving its resistance to wear and corrosion. Various treatments are available, depending on the specific environmental conditions the sprocket will face.

Applications of Metric Bore Sprockets

Metric bore sprockets find widespread application across various industries, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical manufacturing

- Assembly line operations

- Logistics and warehousing solutions

Maintenance and care

Regular maintenance of sprockets is vital to prolong their lifespan and ensure optimal performance. Key maintenance practices include:

-

- Daily inspection

It is imperative to regularly inspect the sprocket for any signs of damage, wear, or misalignment. Early detection of issues can prevent more significant problems down the line.

-

- Cleaning

Keeping the sprocket clean is essential to remove dirt, debris, and lubricant build-up that can impede its functionality. Regular cleaning helps maintain smooth operation and prevents corrosion.

-

- Lubrication

Applying suitable lubrication is crucial for facilitating smooth operation and minimizing wear on the sprocket and chain. Adequate lubrication reduces friction and heat during operation.

-

- Adjustment and calibration

Periodic checks and adjustments of the chain tension and alignment are necessary to maintain proper engagement between the chain and sprocket. This ensures efficient power transfer and reduces wear.

Common problems associated with sprockets include tooth skipping, breakage, wear, excessive noise, and chain detachment. Addressing these issues typically involves:

- Ensuring proper chain tension

- Replacing damaged or worn sprockets promptly

- Applying lubrication as needed

- Correctly aligning the chain and sprocket

- Inspecting and replacing worn-out chains regularly

Metric Bore Sprockets Supplier - GBC

GBC is the sales agent for Ever-power Group in Australia, and we are recognized as one of the leading sprocket suppliers in the region. Our company specializes in high-quality sprockets, including the Metric Bore Sprocket for ISO 10B Roller Chain (15.875mm Pitch). We take pride in our manufacturing standards, ensuring that each sprocket meets rigorous quality benchmarks to provide reliable performance in various applications.

At GBC, we prioritize customer satisfaction and offer comprehensive pre-sale and post-sale services. Our dedicated team is always ready to assist you in selecting the right products for your needs and ensuring a smooth purchasing experience. Furthermore, we understand that every project may have unique requirements, which is why we offer non-standard customizations tailored to our customers' specifications.

Additional information

| Edited by | Sylvia |

|---|

Introducing our Metric Bore Sprocket, designed for ISO 606 and DIN 8187 10B Roller Chain with a 15.875mm pitch. This high-performance sprocket ensures durability and efficiency in various applications, making it an ideal choice for your machinery needs. GBC proudly offers high-quality Metric Bore Sprockets in Australia.