Plain Bore Sprocket NK80B (25.4mm Pitch)

The Plain Bore Sprocket NK80B features a 25.4mm pitch, designed for reliability and efficiency in various industrial applications. Its robust construction ensures durability, making it an excellent choice for power transmission needs. GBC proudly offers high-quality NK80B sprockets in Australia, ensuring top performance and customer satisfaction.

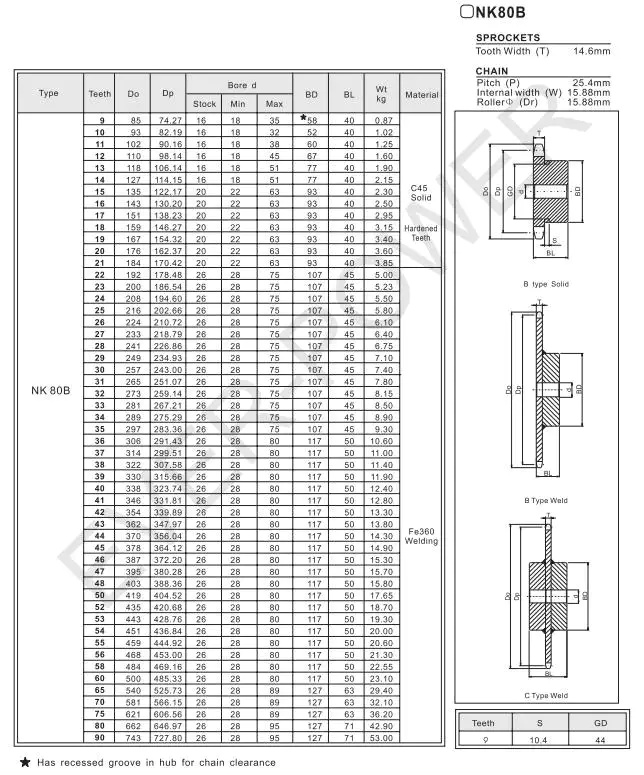

Specifications of Plain Bore Sprocket NK80B (25.4mm Pitch)

The Plain Bore Sprocket NK80B is designed with a standard bore that accommodates a specific shaft size, ensuring a secure fit. This type of sprocket is ideal for applications requiring easy mounting and dismounting, which significantly enhances its versatility across various industrial settings. It enables seamless integration into machinery, thereby improving operational efficiency.

Basic Structure of a Sprocket

A sprocket consists of three primary components: the hub, the chain groove, and the teeth. The hub serves as the central support, while the chain groove is meticulously designed to engage with the specific chain type being utilized. The teeth are crucial for the transmission of power, ensuring smooth operation. When selecting a sprocket, important considerations include material choice, tooth profile, tooth count, dimensions, center bore specifications, keyway requirements, and surface treatments to enhance durability.

Materials and Manufacturing Process

Our sprockets, including the NK80B model, are constructed from premium materials such as high-carbon steel, alloy steel, or stainless steel, tailored according to the intended application. The manufacturing process encompasses a variety of stages, including the selection of raw materials, cutting, stamping, forging, machining, heat treatment, surface hardening, and rust prevention measures. Rigorous quality inspections are conducted throughout to ensure each sprocket meets the highest standards of performance and reliability.

Applications

The NK80B Plain Bore Sprocket is extensively utilized in different sectors, including heavy machinery, food processing, packaging, as well as in chemical and pharmaceutical industries. Its adaptability also makes it suitable for assembly lines, logistics operations, and warehousing environments. These applications illustrate the sprocket's crucial role in enhancing productivity and efficiency in various mechanical systems.

Maintenance and Common Problems

To ensure optimal performance and extend the lifespan of the NK80B sprocket, regular maintenance and thorough inspections are imperative. This maintenance routine includes daily visual checks, cleaning procedures, lubrication, adjustments, and calibration as necessary. Common issues that may arise include skipping teeth, breakage, wear and tear, excessive noise during operation, and chain disengagement. Identifying and addressing these problems promptly is essential for maintaining operational efficiency and preventing unexpected downtimes.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are one of the best sprocket suppliers in Australia. Our commitment to quality ensures that we provide top-notch sprockets, including the Plain Bore Sprocket NK80B with a 25.4mm pitch. Each sprocket undergoes rigorous quality control tests to meet industry standards, guaranteeing durability and performance you can rely on.

In addition to our exceptional products, we pride ourselves on our comprehensive pre-sales and after-sales services. Our knowledgeable team is ready to assist you with any inquiries and provide support throughout your purchasing journey. We also offer non-standard customization based on customer requirements, ensuring that you receive a product tailored to your specific needs.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK80B features a 25.4mm pitch, designed for reliability and efficiency in various industrial applications. Its robust construction ensures durability, making it an excellent choice for power transmission needs. GBC proudly offers high-quality NK80B sprockets in Australia, ensuring top performance and customer satisfaction.