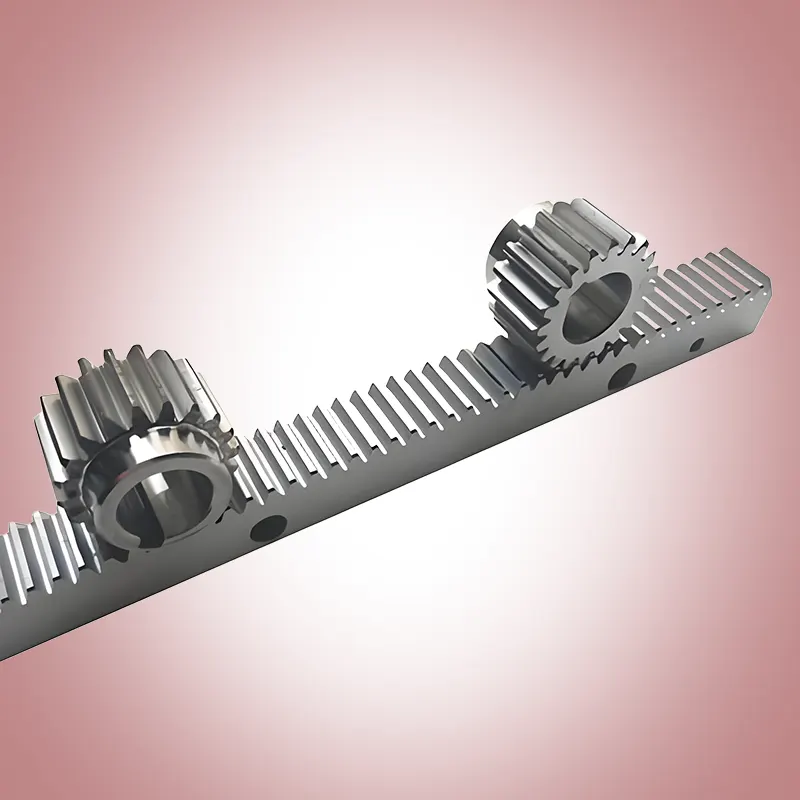

Gear Rack

Gear Racks for Sale

Our broad range of rack products, including plastic gear rack, gear rack for sliding gate and gear racks for construction, meet the unique needs of different industries. Spur gear rack is suitable for linear motion systems with high accuracy and stability. A helical gear rack is favored by machinery manufacturers for its smooth transmission and low noise. Round gear racks and curved gear racks provide flexibility for special curved movements. As one of the top gear rack suppliers in Australia, GBC has a premium gear rack for sale whether you’re looking for a standard product or a custom gear rack.

Spur Gear Rack

Spur gear racks feature straight teeth for precise linear motion. Ideal for automation and machinery, they ensure reliable performance with high accuracy.

Helical Gear Rack

Helical gear racks have angled teeth for smoother, quieter operation. Perfect for high-speed and heavy-load applications, they offer enhanced strength.

Round Gear Rack

Round gear racks are designed for circular motion systems. Their unique shape suits specialized machinery, providing flexibility and consistent motion.

Curved Gear Rack

Curved gear racks enable smooth motion along curved paths. Used in custom setups, they deliver precision for complex, non-linear applications.

Plastic Gear Rack

Plastic gear racks are lightweight and corrosion-resistant. Ideal for light-duty systems, they offer cost-effective solutions with low maintenance needs.

Gear Rack for Sliding Gate

Gear racks for sliding gates ensure reliable gate operation. Durable and easy to install, they provide smooth movement for residential and industrial gates.

Gear Rack for Construction

Gear racks for construction are built for heavy-duty tasks. Robust and wear-resistant, they support cranes, lifts, and other rugged equipment.

Affordable Gear Rack with Fast Delivery

Our company offers a wide range of high-quality rack and guide rail rack models to meet diverse industrial needs. The rack models include CSTGH, CSTMQ, CSTMH, CHTGH, CHTMQ, CHTMH, MSTGH, MSTMQ, MSTMH, MHTGH, MHTMQ, and MHTMH, covering a wide range of specifications and performances, and are suitable for various precision transmission scenarios. The guide rack models include MNVGH-00, MNTGH-00, MSVGH-CP, and MSTGH-CP. They are exquisitely designed to ensure high precision and stability. In addition, we also offer UV series and UR series guide rail rollers to match the guide rail system, providing customers with efficient and reliable motion control solutions.

Ground & Milled Gear Racks

Our company, GBC, has been deeply engaged in the field of transmission components, specializing in providing ground racks and precision milled racks to meet the diverse needs of customers. The grinding rack takes the rack that has been precisely milled or planed as the blank, and is precisely processed by grinding tools and grinding agents. It features smooth transmission, low noise, and strong wear resistance, and is suitable for high-precision equipment such as precision machine tools and robots. The precision milled rack is formed by using high-precision milling machines and numerical control systems, featuring high production efficiency. It can meet the transmission requirements of most industrial scenarios such as ordinary machine tools and logistics conveying equipment, and has both efficiency and cost advantages.

| Item | Grinding Racks | Milling Racks |

|---|---|---|

| Accuracy Grade | Higher (ISO Grade 4 – 6) | Moderate (ISO Grade 7 – 9) |

| Surface Roughness | Ra ≤ 0.8μm | Ra 1.6 – 3.2μm |

| Production Efficiency | Lower (grinding is a slow process) | Higher (milling is suitable for mass production) |

| Cost | High (complex process, time-consuming) | Low (simple process, high efficiency) |

| Application Scenarios | Precision transmission, high-precision equipment | General transmission, medium and low-precision equipment |

Code Explanation

Ground Gear Rack |

|||||||||

| M1 | M1.5 | M2 | M3 | M4 | M5 | M6 | M8 | M10 | M12 |

| MHTGH01005 | MHTGH01505 | MHTGH02005 | MHTGH03005 | MHTGH04005 | MHTGH05005 | MHTGH06005 | MHTGH08005 | MHTGH10010 | CHTGH12010 |

| MSTGH01005 | MHTGH01510 | MHTGH02010 | MHTGH03010 | MHTGH04010 | MHTGH05010 | MHTGH06010 | MHTGH08010 | MSTGH10010 | CSTGH12012 |

| CHTGH01005 | MSTGH01505 | MSTGH02005 | MSTGH03005 | MSTGH04005 | MSTGH05005 | MSTGH06005 | MSTGH08005 | CHTGH10010 | |

| CSTGH01005 | MSTGH01510 | MSTGH02010 | MSTGH03010 | MSTGH04010 | MSTGH05010 | MSTGH06010 | MSTGH08010 | CSTGH10010 | |

| CHTGH01505 | CHTGH02005 | CHTGH03005 | CHTGH04005 | CHTGH05005 | CHTGH06005 | CHTGH08005 | |||

| CHTGH01510 | CHTGH02010 | CHTGH03010 | CHTGH04010 | CHTGH05010 | CHTGH06010 | CHTGH08010 | |||

| CSTGH01505 | CSTGH02005 | CSTGH03005 | CSTGH04005 | CSTGH05005 | CSTGH06005 | CSTGH08005 | |||

| CSTGH01510 | CSTGH02010 | CSTGH03010 | CSTGH04010 | CSTGH05010 | CSTGH06010 | CSTGH08010 | |||

Milled Gear Rack |

|||||||||

| M1 | M1.5 | M2 | M3 | M4 | M5 | M6 | M8 | M10 | M12 |

| MHTMH01005 | MHTMH01505 | MHTMH02005 | MHTMH03005 | MHTMH04005 | MHTMH05005 | MHTMH06005 | MHTMH08005 | MHTMH10010 | CHTMH12010 |

| MHTMQ01005 | MHTMH01510 | MHTMH02010 | MHTMH03010 | MHTMH04010 | MHTMH05010 | MHTMH06010 | MHTMH08010 | MHTMQ10010 | |

| MSTMH01005 | MHTMQ01505 | MHTMQ02005 | MHTMQ03005 | MHTMQ04005 | MHTMQ05005 | MHTMQ06005 | MHTMQ08005 | MSTMH10010 | |

| MSTMQ01005 | MHTMQ01510 | MHTMQ02010 | MHTMQ03010 | MHTMQ04010 | MHTMQ05010 | MHTMQ06010 | MHTMQ08010 | MSTMQ10010 | |

| CHTMH01005 | MSTMH01505 | MSTMH02005 | MSTMH03005 | MSTMH04005 | MSTMH05005 | MSTMH06005 | MSTMH08005 | CHTMH10010 | |

| CHTMQ01005 | MSTMH01510 | MSTMH02010 | MSTMH03010 | MSTMH04010 | MSTMH05010 | MSTMH06010 | MSTMH08010 | CHTMQ10010 | |

| CSTMH01005 | MSTMQ01505 | MSTMQ02005 | MSTMQ03005 | MSTMQ04005 | MSTMQ05005 | MSTMQ06005 | MSTMQ08005 | CSTMH10010 | |

| CSTMQ01005 | MSTMQ01510 | MSTMQ02010 | MSTMQ03010 | MSTMQ04010 | MSTMQ05010 | MSTMQ06010 | MSTMQ08010 | CSTMQ10010 | |

| CHTMH01505 | CHTMH02005 | CHTMH03005 | CHTMH04005 | CHTMH05005 | CHTMH06005 | CHTMH08005 | |||

| CHTMH01510 | CHTMH02010 | CHTMH03010 | CHTMH04010 | CHTMH05010 | CHTMH06010 | CHTMH08010 | |||

| CHTMQ01505 | CHTMQ02005 | CHTMQ03005 | CHTMQ04005 | CHTMQ05005 | CHTMQ06005 | CHTMQ08005 | |||

| CHTMQ01510 | CHTMQ02010 | CHTMQ03010 | CHTMQ04010 | CHTMQ05010 | CHTMQ06010 | CHTMQ08010 | |||

| CSTMH01505 | CSTMH02005 | CSTMH03005 | CSTMH04005 | CSTMH05005 | CSTMH06005 | CSTMH08005 | |||

| CSTMH01510 | CSTMH02010 | CSTMH03010 | CSTMH04010 | CSTMH05010 | CSTMH06010 | CSTMH08010 | |||

| CSTMQ01505 | CSTMQ02005 | CSTMQ03005 | CSTMQ04005 | CSTMQ05005 | CSTMQ06005 | CSTMQ08005 | |||

| CSTMQ01510 | CSTMQ02010 | CSTMQ03010 | CSTMQ04010 | CSTMQ05010 | CSTMQ06010 | CSTMQ08010 | |||

Product Application Industry

|

|

GBC gear racks are suitable for heavy load, high precision, high rigidity, high speed, and long stroke applications.

Application Cases

The application of machine tool equipment

Our rack and pinion features high speed, high precision, low noise, and low wear, providing a linear transmission option for precision machine tools.

For equipment that values high efficiency and precision performance, our grinding rack features can be fully utilized to enhance the performance of the equipment.

- Long stroke CNC gantry machining center

- Woodworking plastic foam and other engraving and milling equipment

- Long stroke milling and drilling equipment for aviation aerospace light rail etc

- Long stroke milling and drilling equipment for automobiles yachts etc

- Cutting and drilling equipment for aluminum alloys and various profiles

- Equipment using non contact methods such as lasers water jets and inkjet printers

Laser Cutting Machine

User: Fiber laser cutting machine manufacturer

Equipment and application: High-speed fiber laser cutting machine

Model: CHTGH02010, CHTGH03010

Reasons for use: High-speed drive, high-precision positioning

Long-stroke Cutting and Drilling Equipment

Users: Production equipment manufacturers, specialized non-standard equipment

Devices and applications: High-precision pipe fitting processing equipment, high-precision profile cutting equipment

Reason for use: High precision and high speed

Select Rack and Pinion Drive

Why Choose GBC Gear Racks?

High Quality Gear Rack Stock to Meet Your Immediate Needs

As a professional gear rack supplier, we offer a wide range of gear rack stock, including straight gear rack, helical gear rack, round gear rack and curved gear rack. Our gear rack for sale is known for its high precision and reliability and is widely used in industrial automation, construction and gating systems. An adequate supply of gear rack stock ensures you can get what you need quickly, without long waits, and help your projects move forward efficiently.

Precision Gear Rack Cutting Process, Customized Diversified Applications

Our industry-leading gear rack cutting technology enables us to produce rack products that meet a wide range of complex needs. From lightweight plastic gear rack to gear rack for construction for heavy duty equipment to gear rack for sliding gate, each rack is finely cut to ensure a perfect fit to your mechanical system. Helical gear rack is favored by customers for its smooth transmission and low noise performance; The curved gear rack and round gear rack provide flexibility for special trajectory movements.

Gear Rack Pitch Selection to Optimize Transmission Performance

When choosing a gear rack, gear rack pitch is a key factor affecting transmission efficiency. Our products are available in a wide range of pitch specifications to meet different needs, from high-precision automation equipment to heavy-duty construction machinery. Whether it’s a gear rack for construction requiring high load capacity or a straight gear rack requiring fine motion, we have the right gear rack pitch for you. As a trusted gear rack supplier, we ensure the stable and durable performance of each rack through strict quality control.

Reasonable Gear Rack Price, Taking into Account Quality and Cost

We are committed to providing cost-effective gear rack for sale, allowing customers to get quality products at a reasonable gear rack price. Whether it’s plastic gear rack for lightweight equipment or gear rack for sliding gate for gating systems, our products are priced transparently and competitively. Thanks to advanced production processes and efficient supply chain management, we control the gear rack price while maintaining quality, saving costs for your projects. With our gear rack, you’ll get the perfect balance of performance and economy.

Contact Us for Custom Gear Rack Solution

Looking for reliable gear rack suppliers? Look no further! Our extensive gear rack stock boasts a diverse range of types, including round gear racks, helical gear racks, and curved gear racks. We also offer professional gear rack-cutting services to precisely meet your individual needs, ensuring a perfect fit for your applications.

What’s more, our gear racks have made a significant impact on the Australian market. They’ve successfully covered states like New South Wales, Victoria, and Queensland and are actively selling in major cities such as Sydney, Melbourne, Brisbane, Adelaide, and Perth.

Browse our catalog today to explore and select the gear rack that’s right for you. Enjoy the convenience of fast shipping and our attentive customer support throughout your purchasing journey. Let’s collaborate to create an efficient and reliable mechanical transmission system tailored to your requirements!